Preparation of transient metal doped nano zinc oxide crystal whisker

A nano-zinc oxide and zinc oxide whisker technology is applied in chemical instruments and methods, zinc oxide/zinc hydroxide, single crystal growth, etc. Uniformity and other problems, to achieve the effect of simple process flow, wide raw material route and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

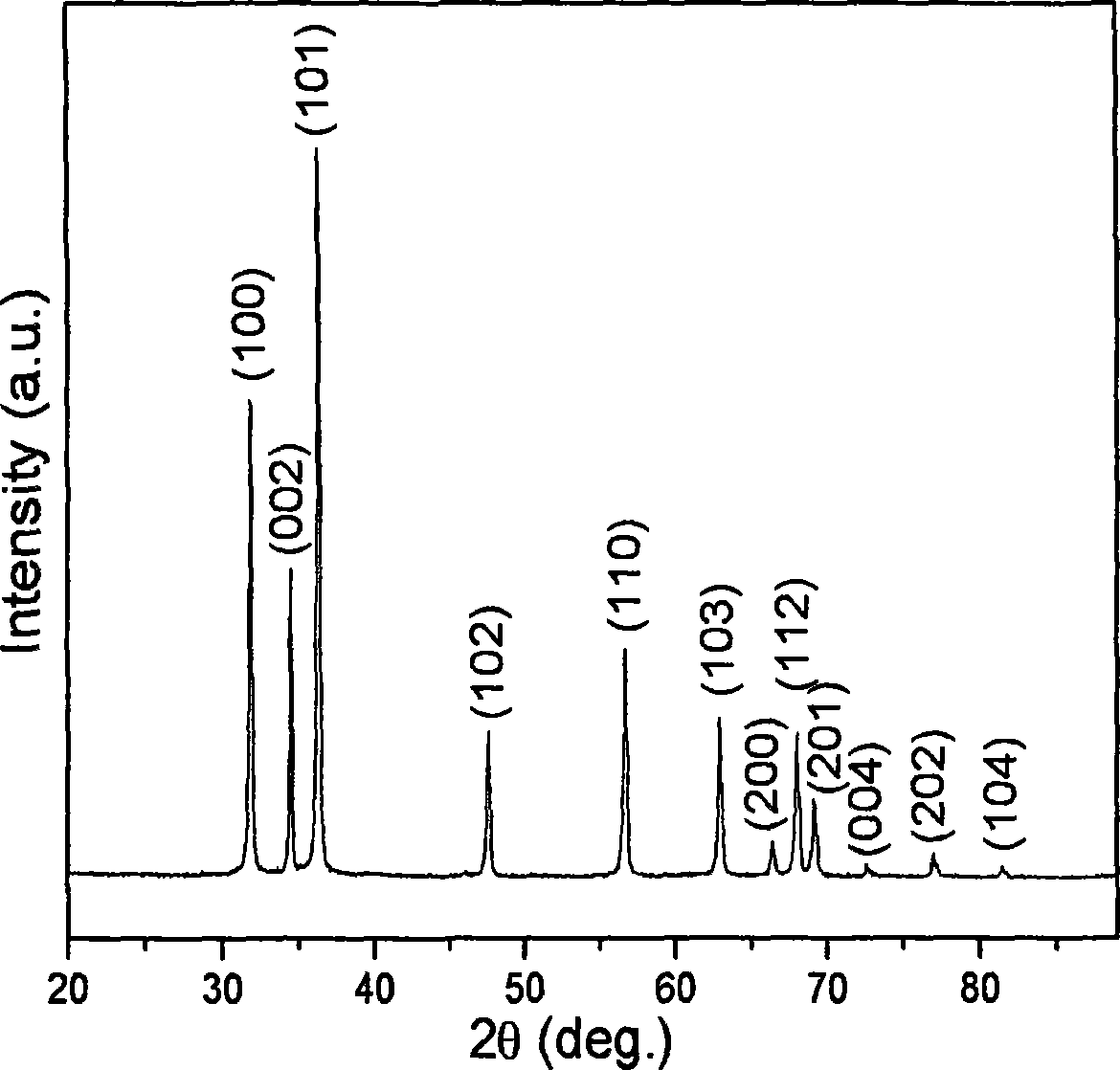

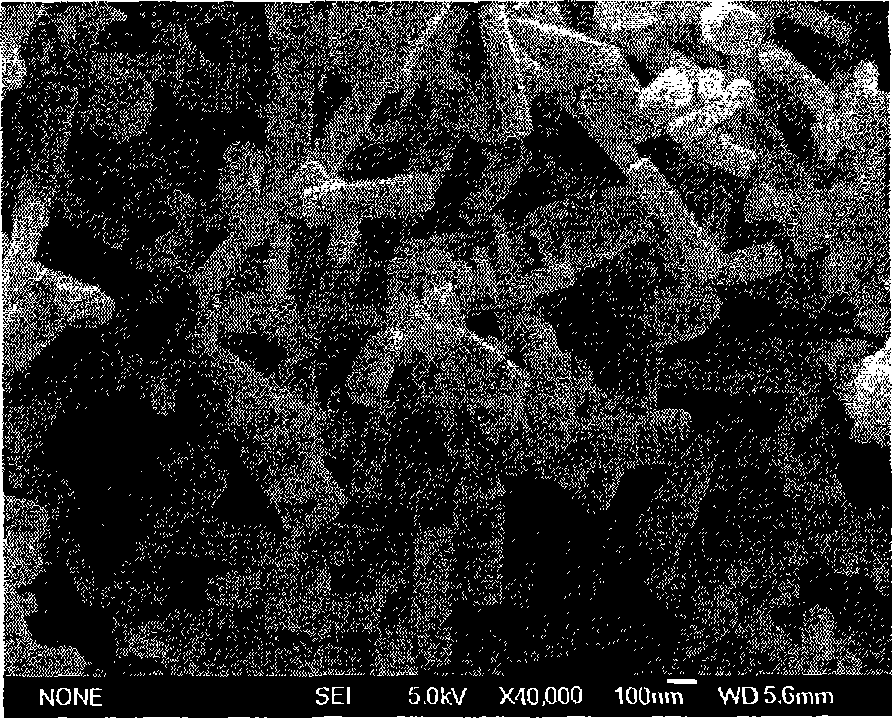

[0027] The raw materials are zinc powder and 2% manganese chloride, which are mixed and sieved and added to the feeding tank. During the experiment, the raw material was added to the plasma at 20 g / min. The plasma parameters are as follows:

[0028] central air

[0029] The product is collected by the receiving tank, and the structure analysis of the product is shown in the attachment figure 1 , product morphology analysis see appendix figure 2 And attached image 3 , the elemental analysis of the product is shown in the appendix Figure 4 .

Embodiment 2

[0031] The raw materials are zinc powder and 0.25% manganese chloride, which are mixed and sieved and added to the feeding tank. During the experiment, the raw material was added to the plasma at 20 g / min. The plasma parameters are as follows:

[0032] central gas

[0033] The product is collected by the receiving tank, and the product morphology analysis is shown in the attached Figure 5 .

Embodiment 3

[0035] The raw materials are zinc powder and 0.25% manganese chloride, which are mixed and sieved and added to the feeding tank. During the experiment, the raw material was added to the plasma at 20 g / min. The plasma parameters are as follows:

[0036] central air

[0037] The product is collected by the receiving tank, and the product morphology analysis is shown in the attached Image 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com