Tea leaf drying device

A technology of a tea drying device and a drying cylinder is applied in the direction of tea processing before extraction, etc., which can solve the problems of inability to achieve continuous drying of tea leaves, deterioration of tea quality, low production efficiency, etc., and achieves reduction of heat loss, energy consumption, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

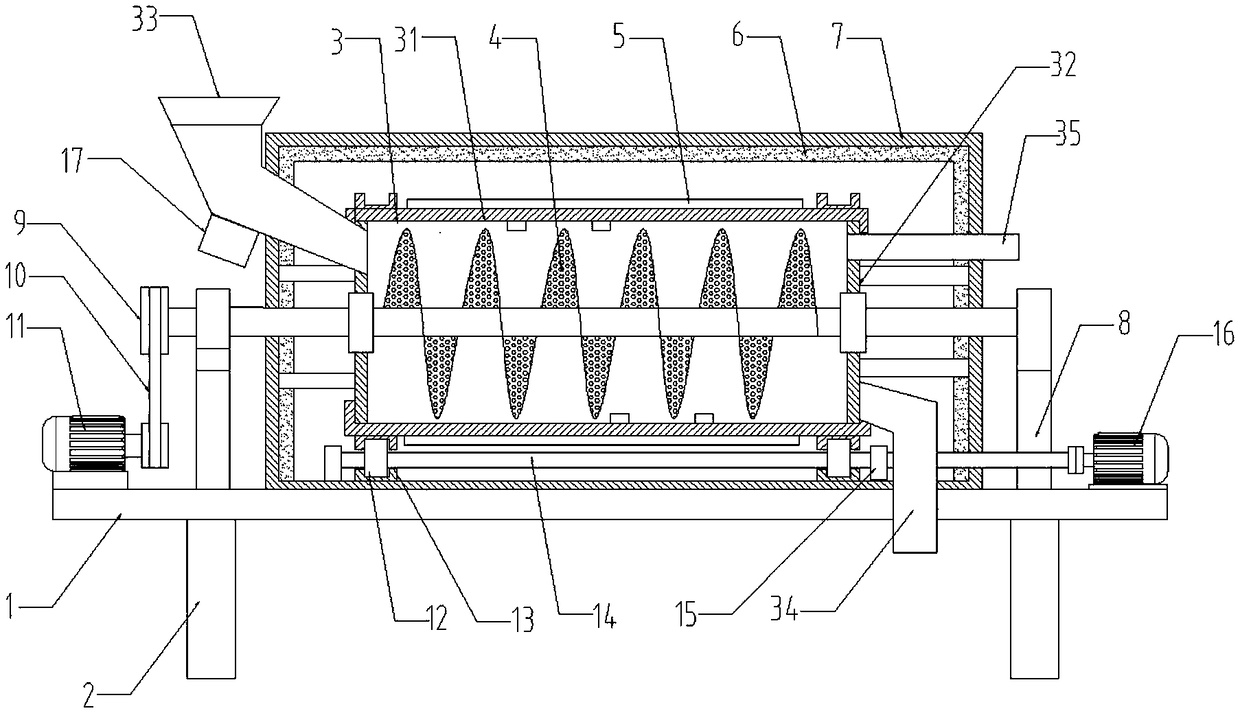

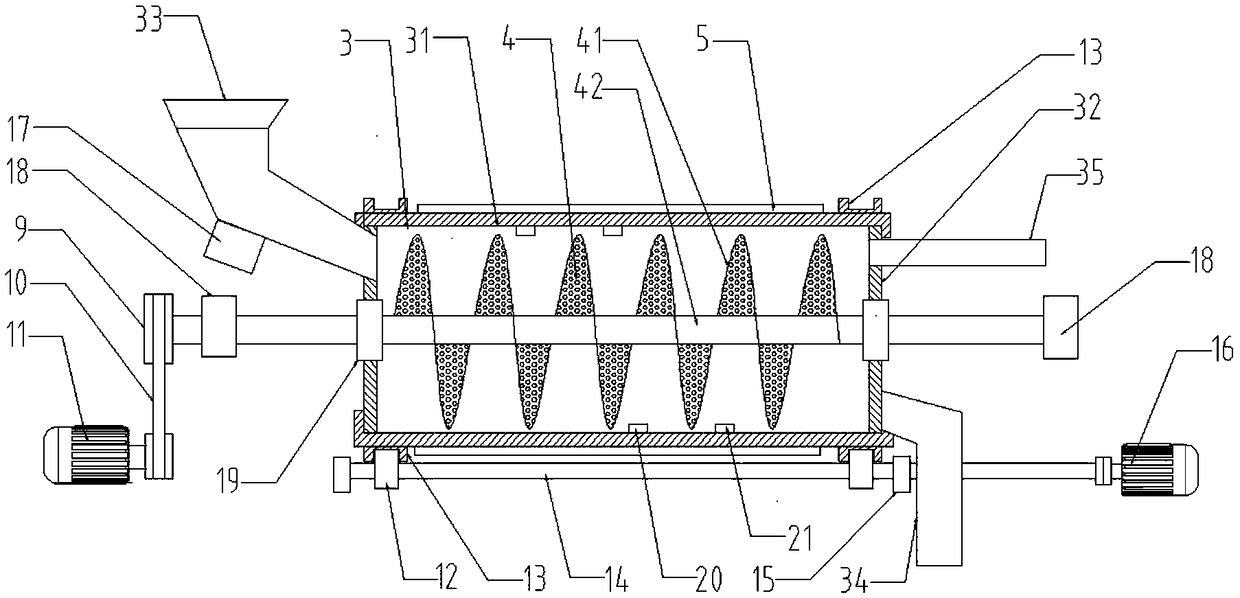

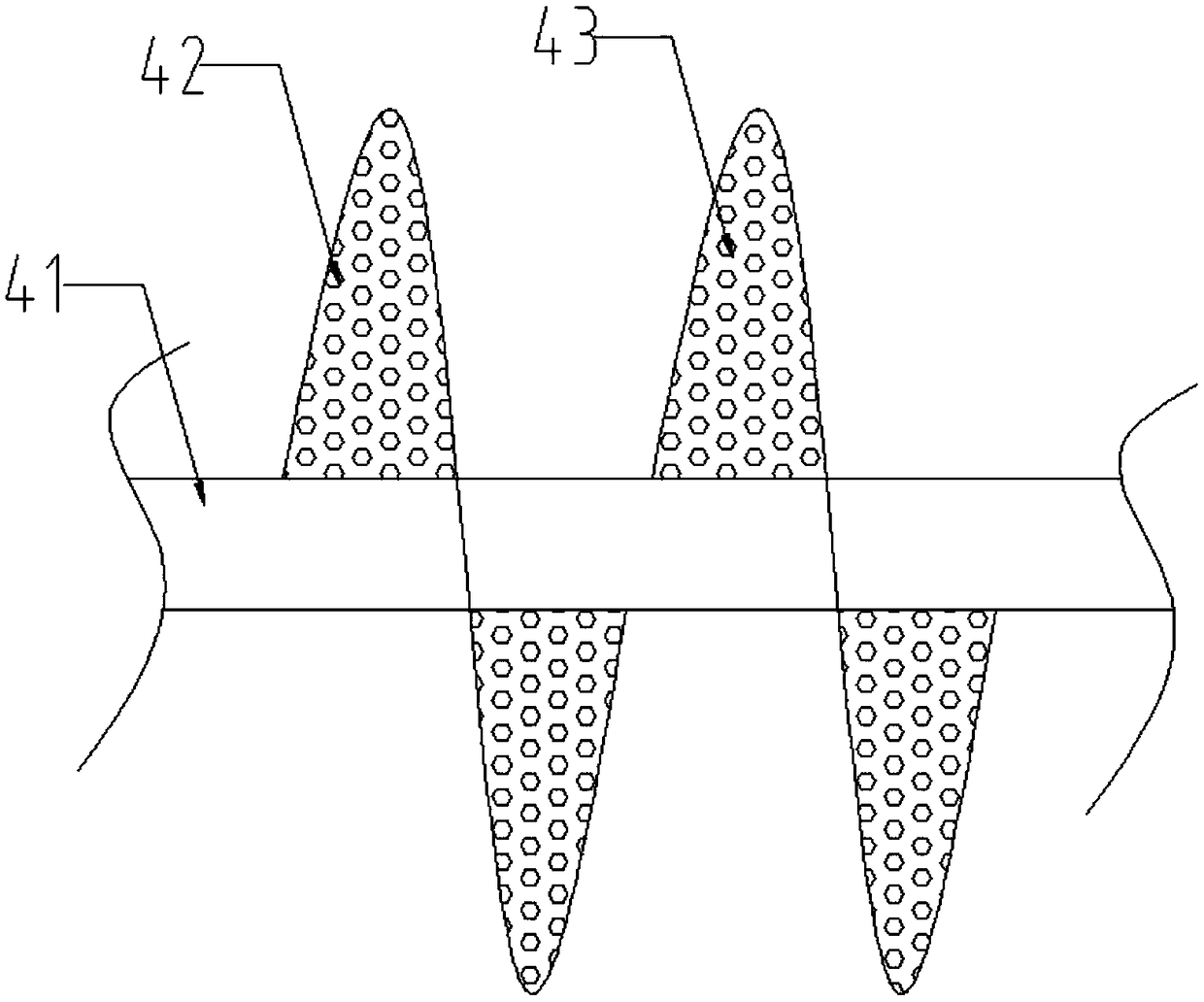

[0029] see Figure 1-3 , the present embodiment provides a tea drying device, comprising a bracket 1, a drying cylinder 3; the outside of the drying cylinder 3 is provided with a thermal insulation cylinder 7, the interior of the thermal insulation cylinder 7 is provided with a thermal insulation layer 6, and the thermal insulation cylinder 7 Installed on the bracket 1, the lower part of the bracket 1 is provided with a leg 2; the inside of the drying cylinder 3 is provided with a screw feeder 4, and the screw feeder 4 is driven by a first motor 11; the drying cylinder 3 includes a cylinder body 31 And side plate 32, described side plate 32 is positioned at cylinder body 31 two ends, and side plate 32 is connected with cylinder body 31 slidingly, and described side plate 32 is fixedly connected with insulating tube 7 inner wall by connecting plate; Described cylinder body 31 outer surface An electric heating plate 5 is arranged, and a plurality of rollers 12 are arranged at th...

Embodiment 2

[0039] see Figure 1-3 In this embodiment, on the basis of Embodiment 1, a vibration motor 17 is arranged on the feeding hopper 33, and the operation of the vibration motor 17 makes the tea leaves evenly enter the drying cylinder 3 for drying, preventing the tea leaves in the feeding hopper 33 from clogging and reducing Productivity.

[0040] Working principle of the present invention:

[0041] The present invention provides a tea drying device. Fresh tea leaves are put into the hopper 3, the first motor 11 runs to drive the screw feeder 4 to rotate, the second motor 16 runs to drive the roller 12 to rotate, and the roller 12 rolls to drive the barrel 31 Rotate, the heating plate 5 heats the drying cylinder 3; the tea leaves are fed to the discharge port under the function of the screw feeder 4, the spiral blade 42 rotates to stir-fry the tea leaves, and the cylinder 31 rotates to increase the stir-fry effect of the tea leaves. Make the tea leaves dry evenly, speed up the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com