Method for continuous preparation of copper zinc tin sulfur film

A copper-zinc-tin-sulfur, thin-film technology, applied in sustainable manufacturing/processing, climate sustainability, final product manufacturing, etc., can solve problems such as heat and mass transfer limitations, decreased product uniformity, loss of function, etc. Simple process and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

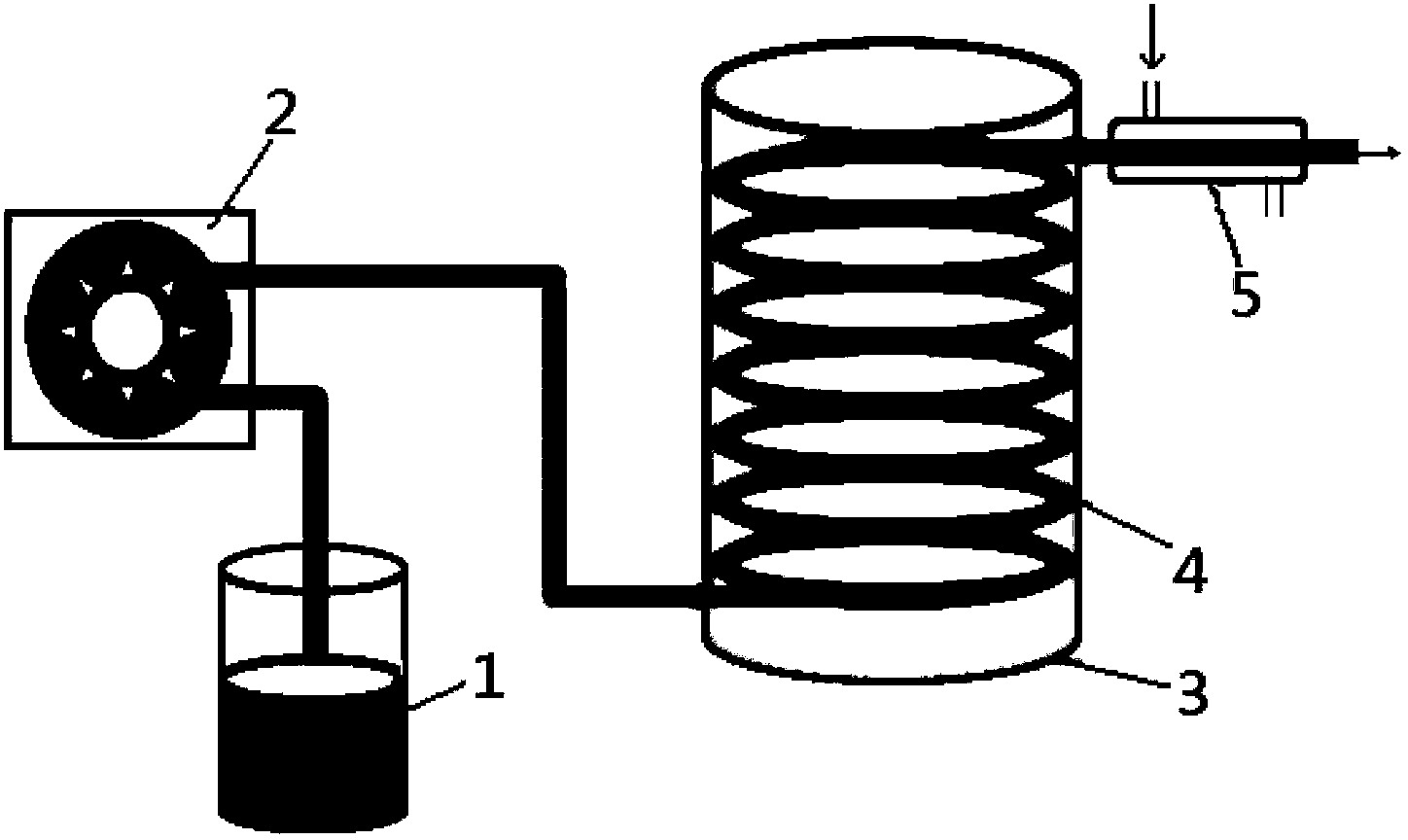

[0038] The preparation method of the above-mentioned copper-zinc-tin-sulfur thin film is different from the existing preparation method: the metal cation solution is first used to coat the film and then vulcanized by sulfur, but the reaction precursor solution system containing four sources is prepared first, and then the heating reaction, purification, coating The drying of the membrane and the selenium sulfurization treatment ensure the preparation of a thin film with good photoelectric conversion performance and stable performance. At the same time, the preparation method of the above-mentioned copper-zinc-tin-sulfur thin film adopts ingenious design to realize continuous and mass production, breaking the conventional laboratory production mode.

[0039] Now, the present invention will be further described in detail by taking the method for continuously preparing copper-zinc-tin-sulfur thin films as an example. Wherein, the substrate is a glass substrate, which is cut into ...

Embodiment 1

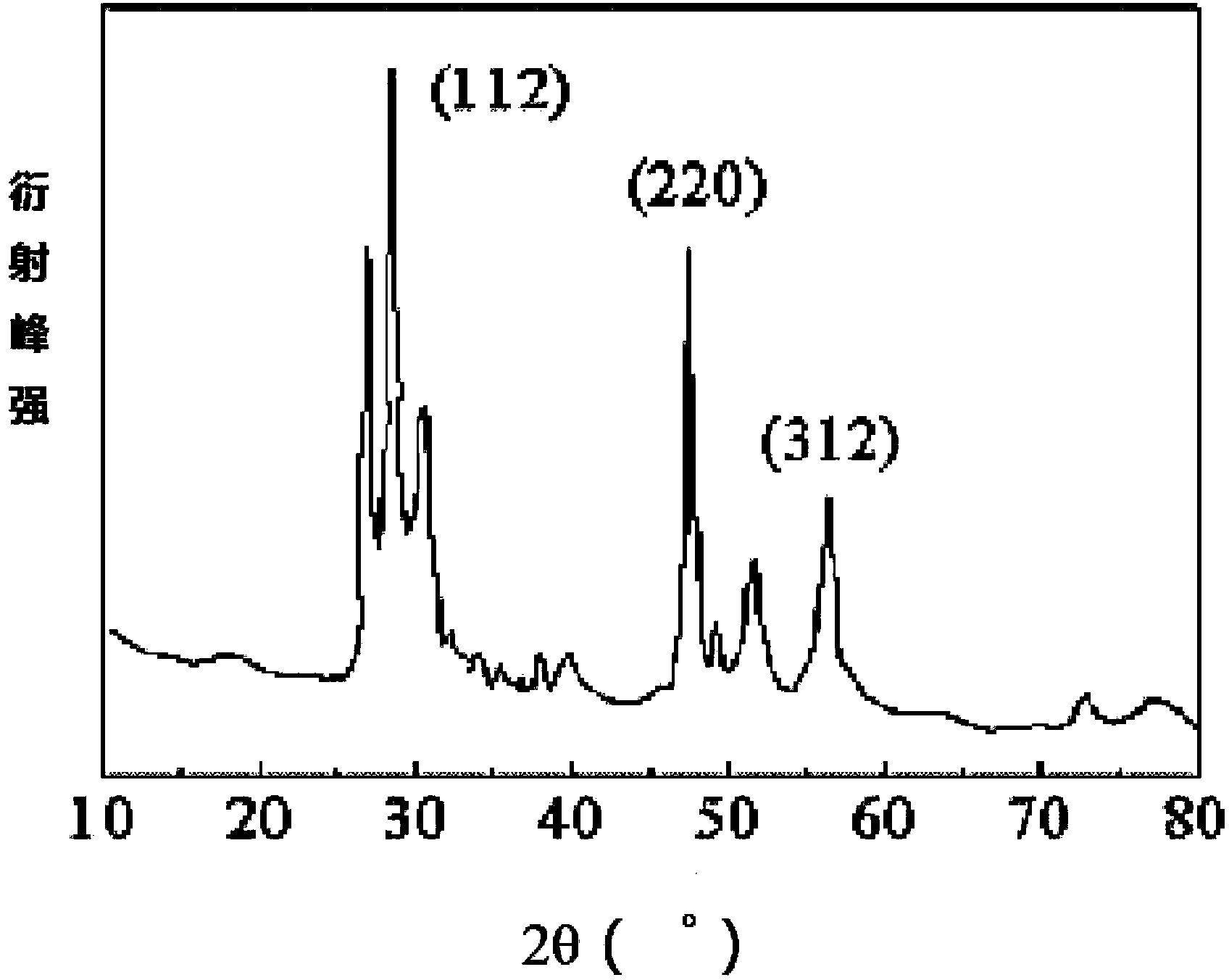

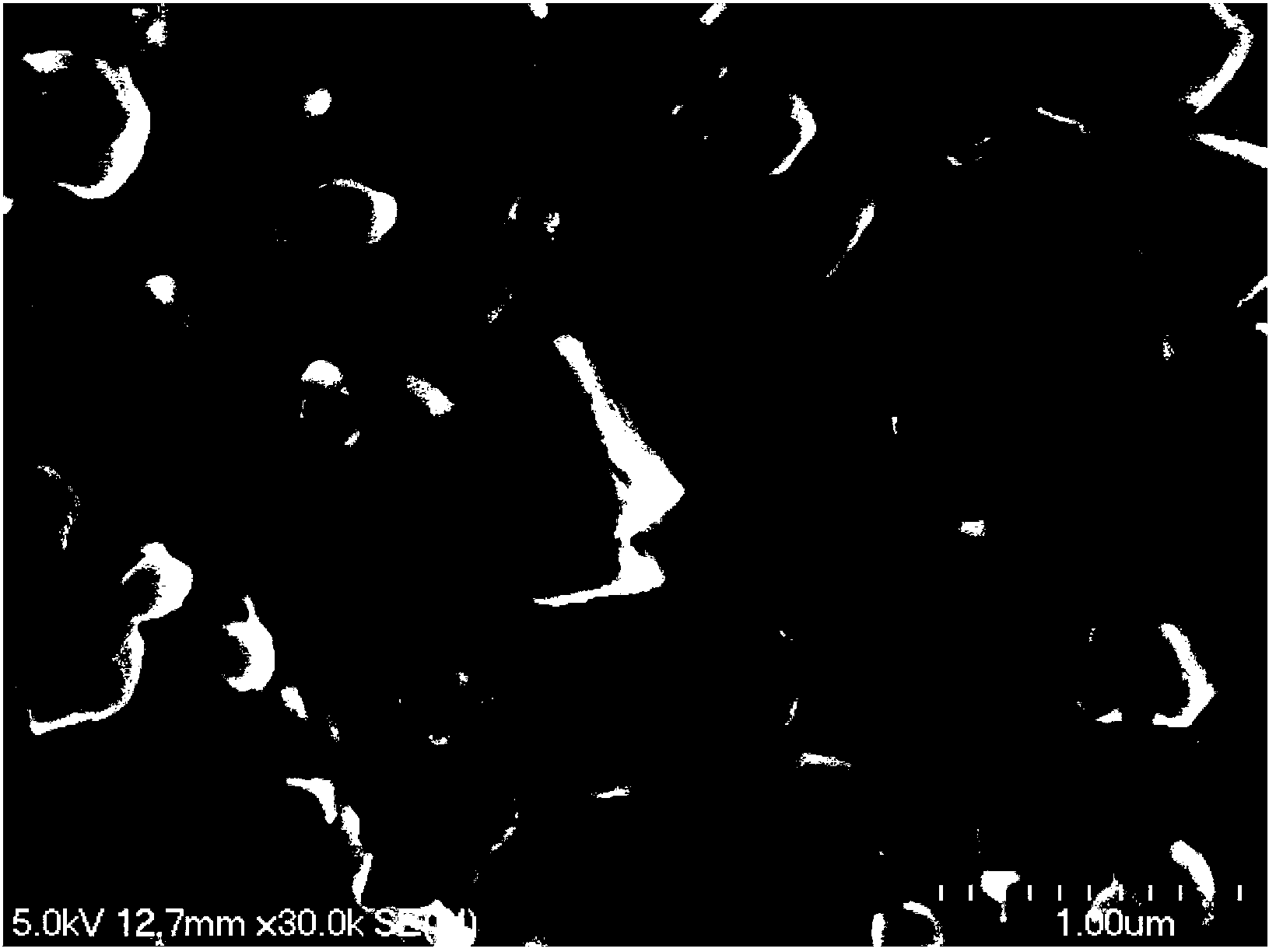

[0041] A method for continuously preparing copper-zinc-tin-sulfur (hereinafter referred to as CZTS) thin films in a flow reactor, comprising the steps of:

[0042] 1) Preparation of reaction precursor solution

[0043] The reactive precursor solution for continuous flow consists of SnCl 4 , CuCl 2 , Sulfur powder and ZnO are dissolved in a mixture of oleylamine and octadecene. Specific preparation method: in 2.0mmolCuCl 2 ·H 2 O and 1.0 mmol SnCl 4 ·5H 2 A small amount of THF (tetrahydrofuran) was added to the O mixture to increase the SnCl 4 Solubility in oleylamine, add THF (tetrahydrofuran) dropwise until the copper source and tin source are completely dissolved. After completely dissolving, 1.0 mmol of ZnO and 39 mL of oleylamine were added to the above mixed solution. The mixed solution was then heated to 50 °C in a rotary evaporator. After the ZnO was completely dissolved, the internal pressure in the rotary evaporator was reduced to 0.5 KPa to remove THF and ot...

Embodiment 2

[0056]A method for continuously preparing copper-zinc-tin-sulfur (hereinafter referred to as CZTS) thin films in a flow reactor, comprising the steps of:

[0057] 1) Preparation of reaction precursor solution

[0058] The reactive precursor solution for continuous flow consists of SnCl 2 2H 2 O, CuSO 4 ·5H 2 O, ZnCl 2 And thiourea is dissolved in a mixture of dodecylamine and octadecene to form. Specific preparation method: in 0.2mmol CuSO 4 ·5H 2 O and 0.1 mmol SnCl 2 2H 2 A small amount of THF (tetrahydrofuran) was added to the O mixture to increase the SnCl 2 Solubility in dodecylamine, add THF (tetrahydrofuran) dropwise until the copper source and tin source are completely dissolved. After complete dissolution, add 0.1 mmol of ZnCl 2 and 20 mL of dodecylamine were added to the above mixed solution. The mixed solution was then heated to 80 °C in a rotary evaporator. in ZnCl 2 After complete dissolution, the internal pressure in the rotary evaporator was reduce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com