Low thermal radiation type fiber reinforced composite for lighting, daylighting panel and preparation method thereof

A fiber-reinforced, composite material technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as high power consumption, avoid energy loss, block infrared rays, and achieve continuous mass production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

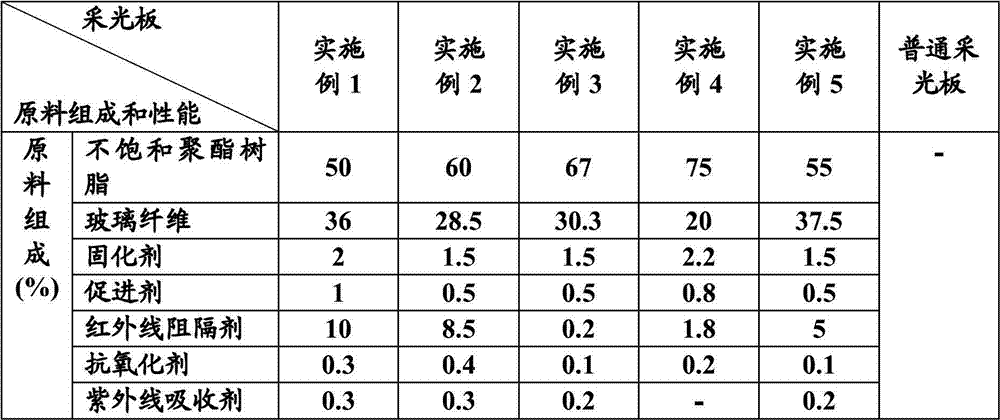

Embodiment 1

[0049] This embodiment provides a daylighting board, whose raw material composition and dosage are shown in Table 1, wherein: the unsaturated polyester resin is propylene glycol phthalate (purchased from Changzhou Huake Resin Co., Ltd.); the diameter of the glass fiber is 8-14 Micron (model T984, purchased from Taishan Glass Fiber Co., Ltd.); Infrared blocking agent (model GTO, purchased from Shanghai Huzheng Nano Technology Co., Ltd.); curing agent is methyl ethyl ketone peroxide; accelerator is zinc isooctanoate; antioxidant is 3,5-di-tert-butyl-4-hydroxyphenyl propanoic acid stearyl ester, tris(2,4-di-tert-butylphenyl) phosphite and tetratyl (3,5-di-tert-butyl Base-4-hydroxyphenylpropionic acid) methyl ester is composed of 1:1:1 by mass ratio; the ultraviolet absorber is 2-(2'-hydroxyl-5'-methylphenyl)benzotriazole; light stabilizer For bis (2,2,6,6-tetramethylbenzene piperidine agent) sebacate.

[0050] The preparation method of the lighting board is as follows:

[0051]...

Embodiment 2

[0056] This embodiment provides a daylighting board, its raw material composition and dosage refer to Table 1, wherein: the unsaturated polyester resin is ethylene glycol isophthalate (purchased from Changzhou Huake Resin Co., Ltd.); the diameter of the glass fiber is 8 ~14 microns (model T984, purchased from Taishan Glass Fiber Co., Ltd.); infrared blocking agent (model GTO, purchased from Shanghai Huzheng Nano Technology Co., Ltd.); curing agent is methyl ethyl ketone peroxide; accelerator is zinc isooctanoate; The oxidant is 3,5-di-tert-butyl-4-hydroxyphenyl propionate stearyl ester; the ultraviolet absorber is phenyl o-hydroxybenzoate; the light stabilizer is three (1,2,2,6,6- Pentamethylpiperidinyl) phosphite.

[0057] The preparation method of the lighting board is as follows:

[0058] (1), add unsaturated polyester resin, accelerator, auxiliary agent, and infrared ray blocking agent into the mixer according to the ratio in Table 1, stir, and wait until completely unifo...

Embodiment 3

[0063] The present embodiment provides a daylighting board, its raw material composition and dosage refer to Table 1, wherein: the unsaturated polyester resin is neopentyl glycol phthalate (purchased from Shanghai Tianhe Resin Co., Ltd.); the diameter of the glass fiber Be 8~14 microns (model T984, purchased from Taishan Glass Fiber Co., Ltd.); Infrared blocking agent (model GTO, purchased from Shanghai Huzheng Nano Technology Co., Ltd.); Curing agent is benzoyl peroxide; Accelerator is octanoic acid cobalt; antioxidant is 3,5-di-tert-butyl-4-hydroxyphenyl propionate stearyl ester; UV absorber is phenyl o-hydroxybenzoate; photostabilizer is tris(1,2,2,6 , 6-pentamethylpiperidinyl) phosphite.

[0064] The preparation method of the lighting board is as follows:

[0065] (1), add unsaturated polyester resin, accelerator and auxiliary agent into the mixer according to the ratio in Table 1, stir, and wait until completely uniform for later use;

[0066] (2), mix the mixture obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com