External circular reaction device suitable for hydrogenation exothermic reaction

A reaction device and exothermic reaction technology, applied in the field of external circulation hydrogenation reactors, can solve the problems of difficult control of hydrogenation reaction temperature, easy coking coverage of reactants, catalyst deactivation, etc., to avoid carbon deposition or coking during polymerization, avoid Effects of polymerization carbon deposition and reaction temperature balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but this does not limit the protection scope of the present invention.

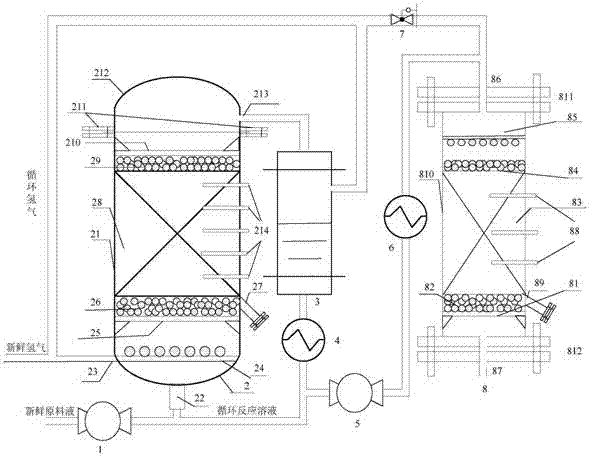

[0019] figure 1 It is a structural schematic diagram of the reaction device of the present invention.

[0020] The reaction device consists of a first feed pump 1, a primary hydrogenation reactor 2, a gas-liquid separator 3, a first heat exchange device 4, a second feed pump 5, a second heat exchange device 6, a pressure and flow stabilization Device 7 and secondary hydrogenation reactor 8 are formed;

[0021] The first-stage hydrogenation reactor 2 is provided with a first gas-liquid distribution device 24 at its lower part, a first support plate 25 is provided above the first gas-liquid distribution device 24, and a first packing layer 26 is sequentially provided on the first support plate 25 , the first catalyst bed 28, the second packing layer 29 and the pressure plate 210, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com