Patents

Literature

38results about How to "Production applicable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

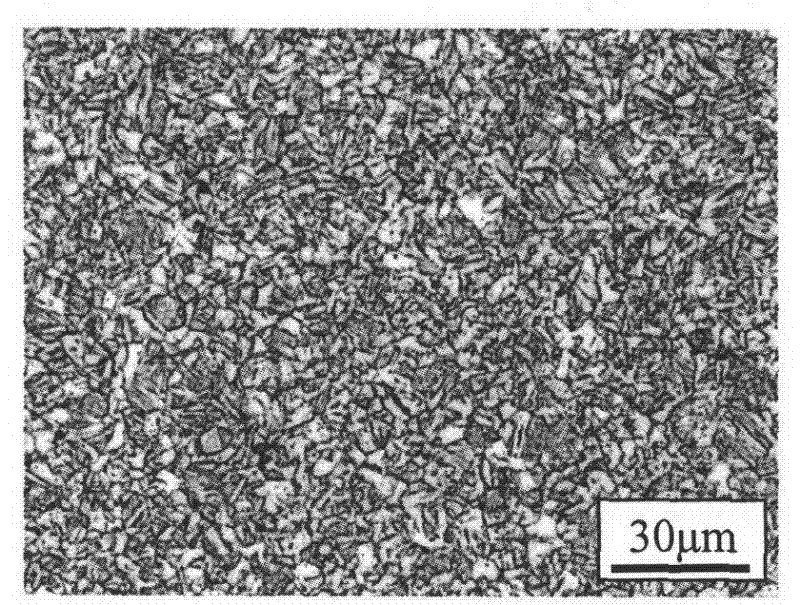

Easy-welding low-carbon bainitic steel and manufacturing method thereof

InactiveCN101787489ASimple production processProduction applicableTemperature control deviceMetal rolling arrangementsChemical compositionBoron

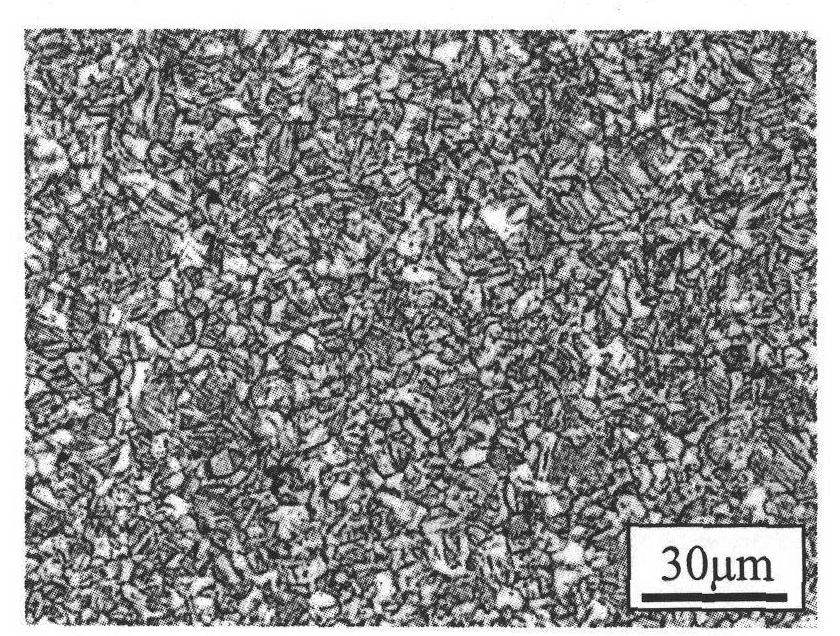

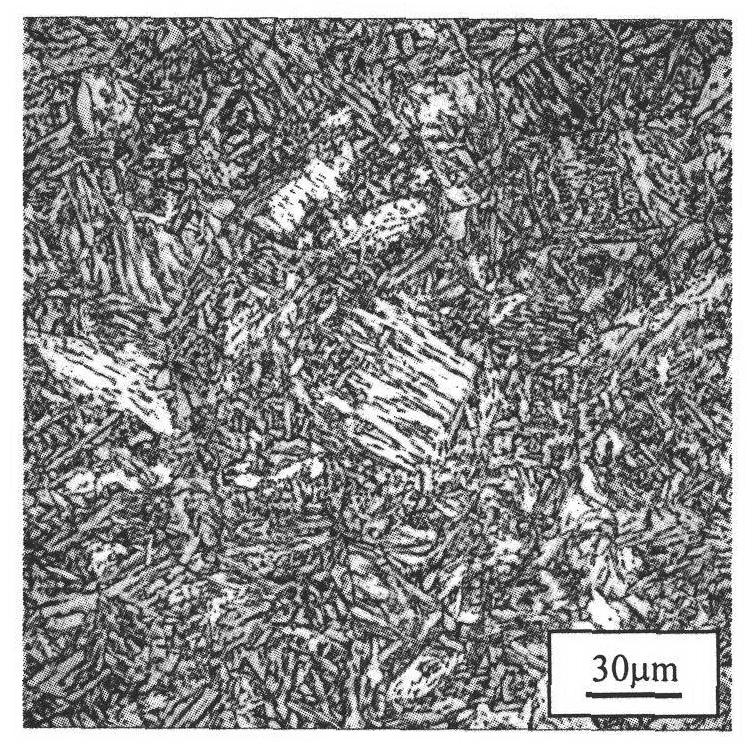

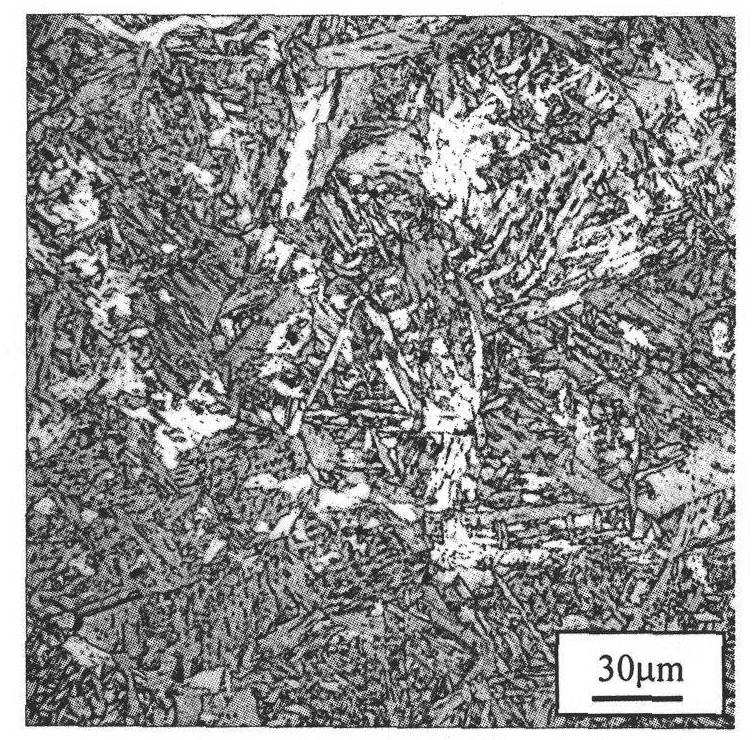

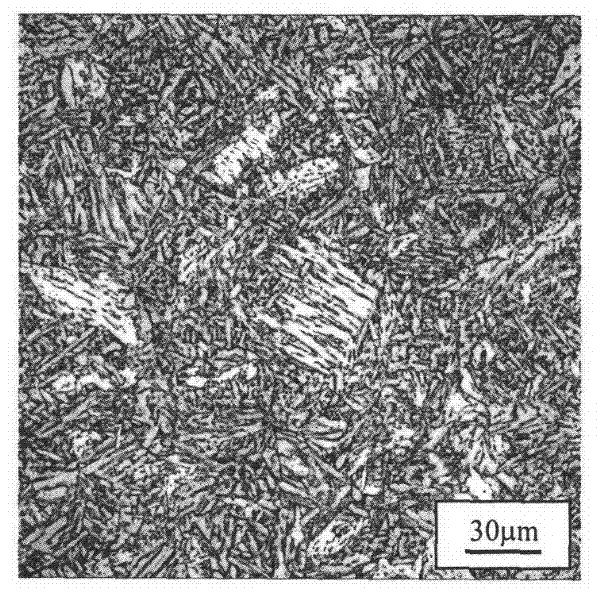

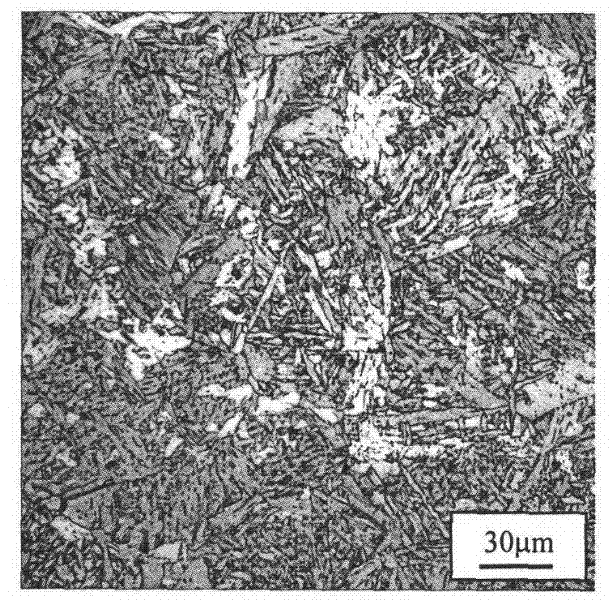

The invention discloses an easy-welding low-carbon bainitic steel and a manufacturing method thereof, belonging to the technical field of microalloy steel. The steel comprises the chemical components by weight percent: 0.02-0.08% of C, 1.20-1.80% of Mn, 0.10-0.50% of Si, less than or equal to 0.010% of S, less than or equal to 0.015% of P, 0.10-0.30% of Mo, 0.020-0.050% of Nb, 0.03-0.10% of V, 0.005-0.030% of Ti, 0.0050-0.010% of N, 0.0005-0.0020% of B, less than or equal to 0.035% of Al and balance of Fe and inevitable impurities. The proportion between the boron content and the nitrogen content in the steel simultaneously meets the conditions that 3N-10B is more than or equal to 0.005 and less than or equal to 0.015, and Ti+V+10B is more than or equal to 8.525N. The production process of smelting by an electric furnace or a converter, external refining, continuous casting and controlled rolling and cooling is adopted. The invention has the advantages that the yield strength of the steel is more than or equal to 550MPa, the tensile strength is more than or equal to 670MPa, the elongation is more than or equal to 20%, and the charpy impact energy under -40 DEG C is more than or equal to 200J; the charpy impact energy under -40 DEG C in a near weld zone is more than or equal to 100J when the weld heat input is 20-100Kj / cm; and the production process is simple and convenient.

Owner:YANSHAN UNIV

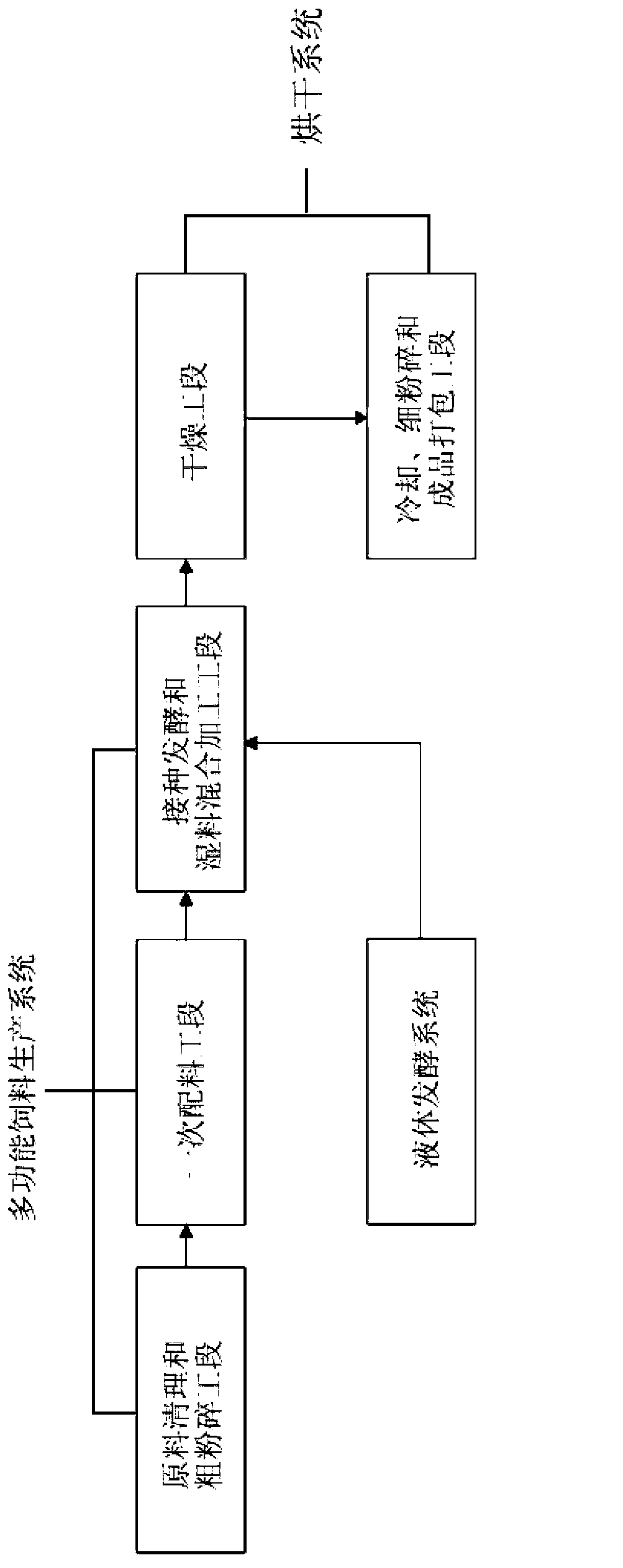

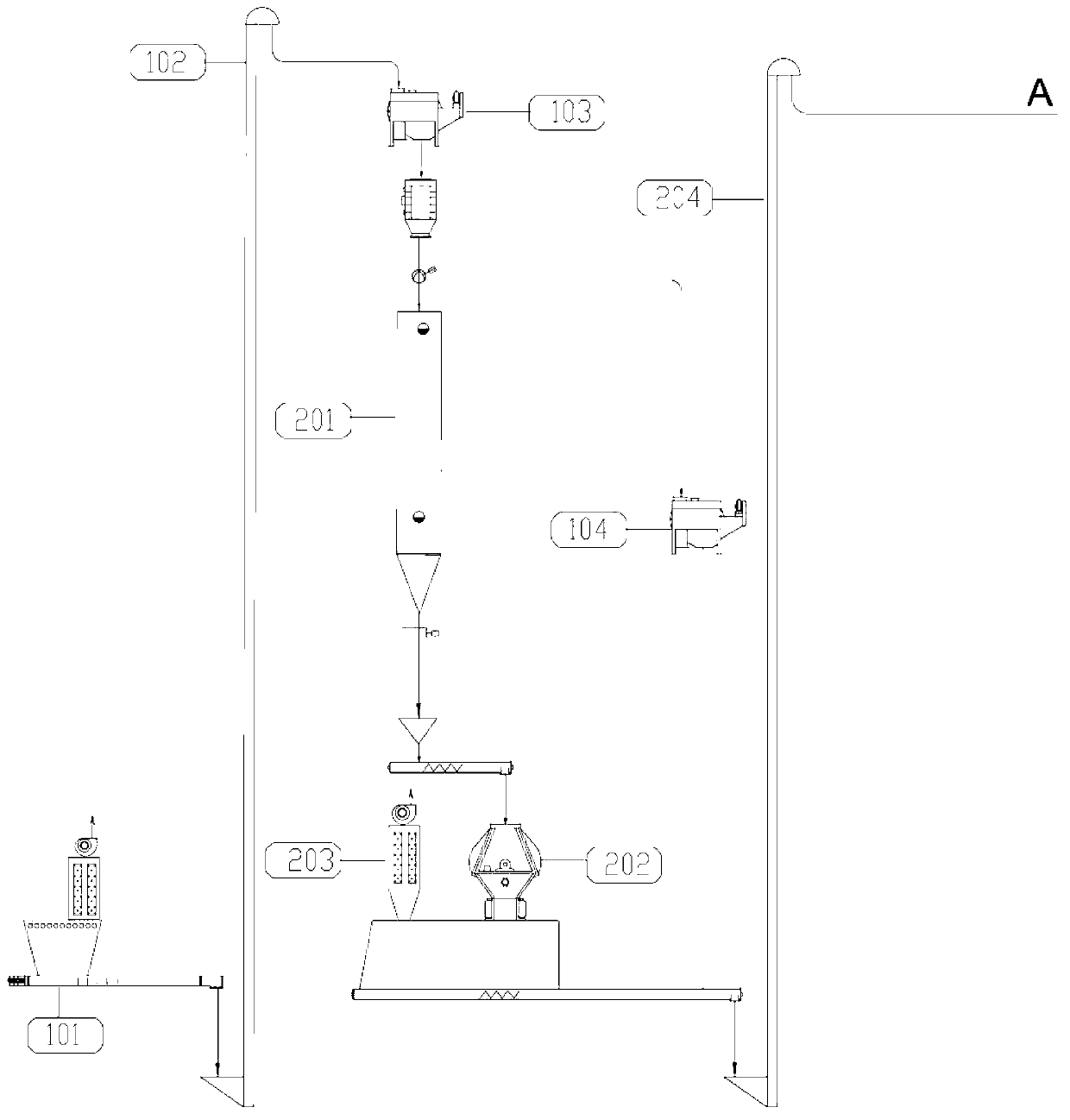

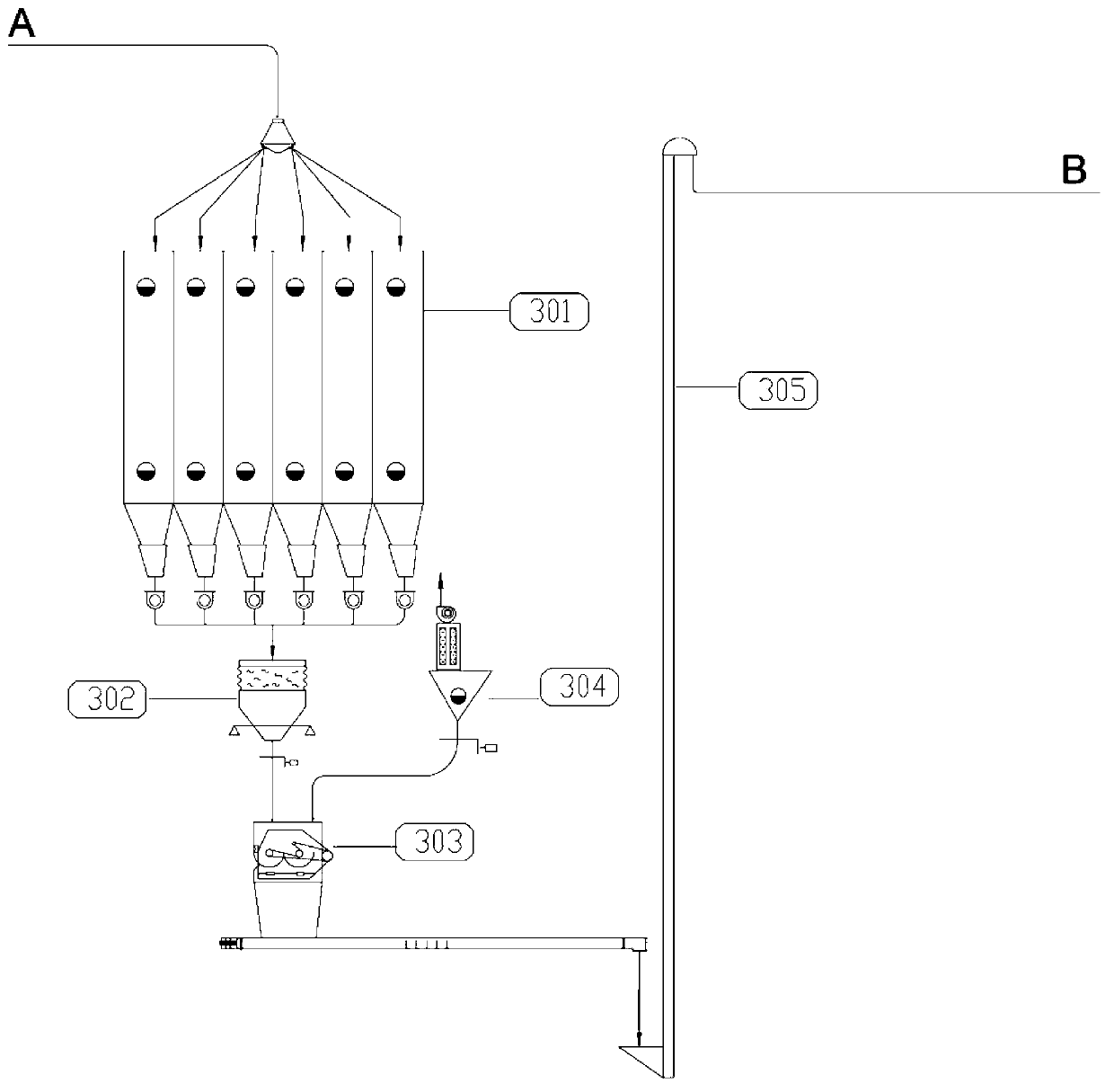

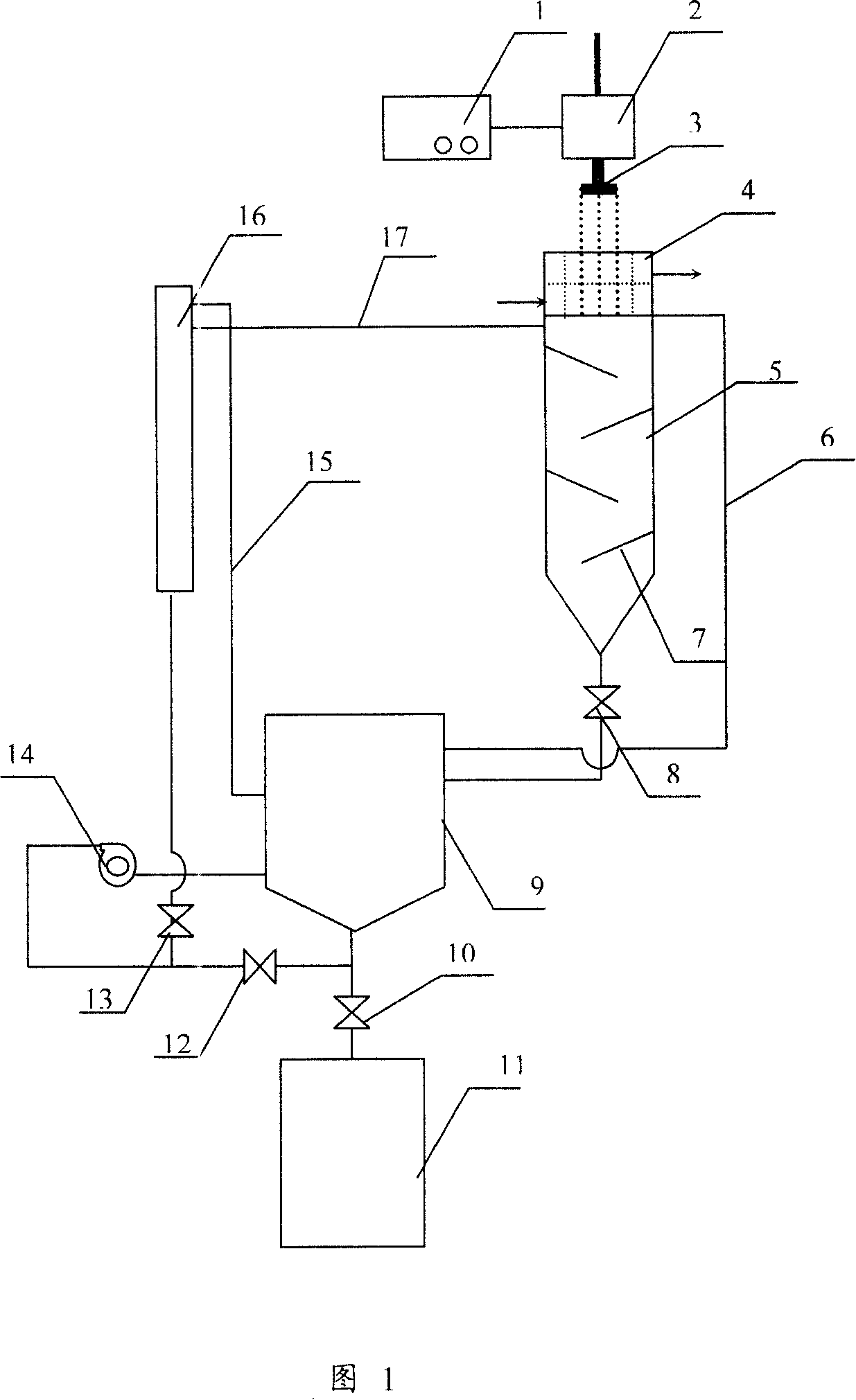

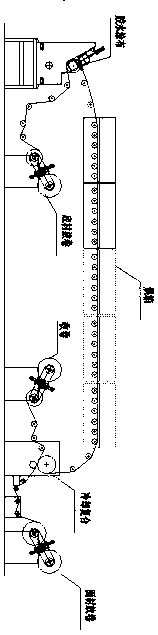

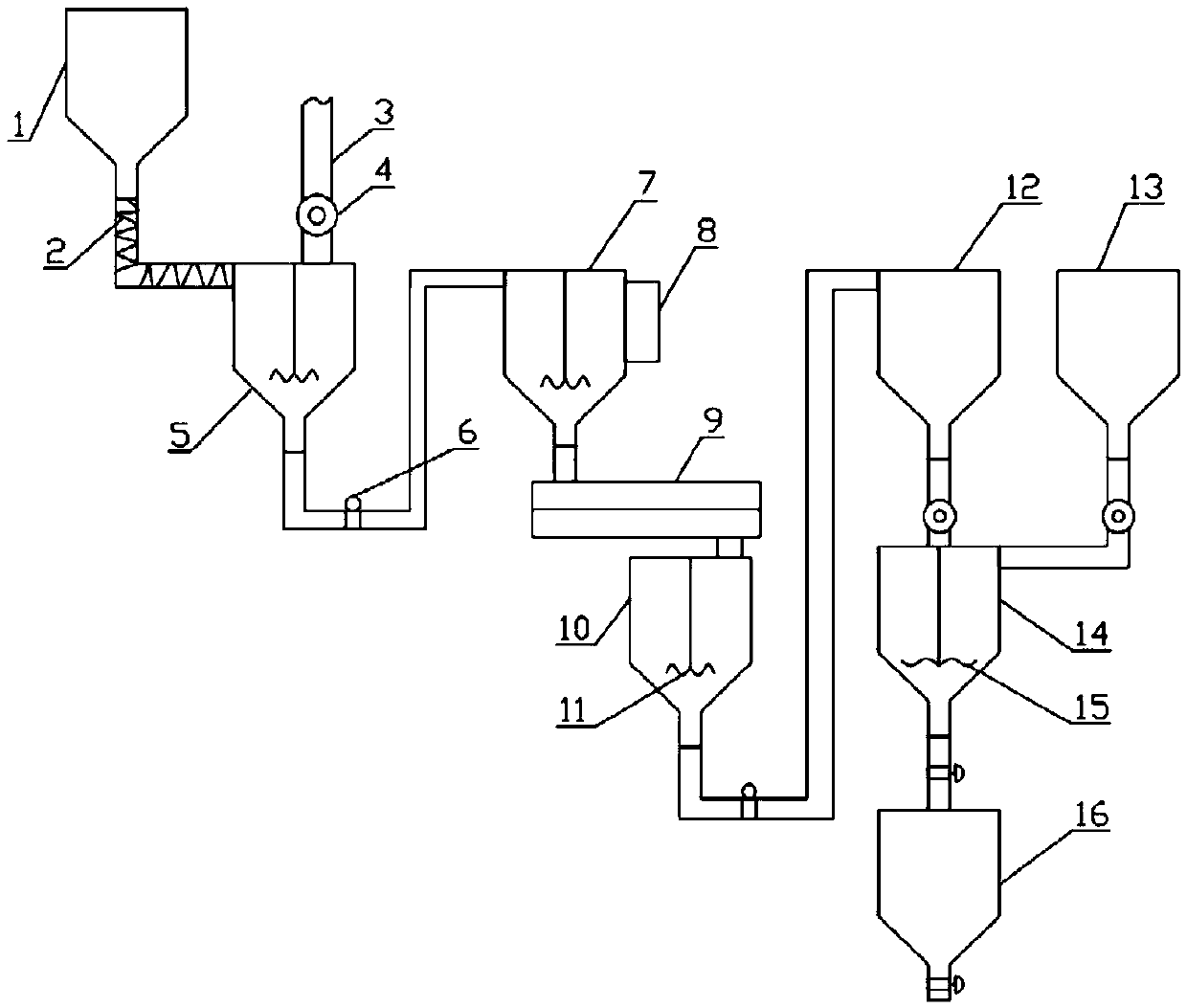

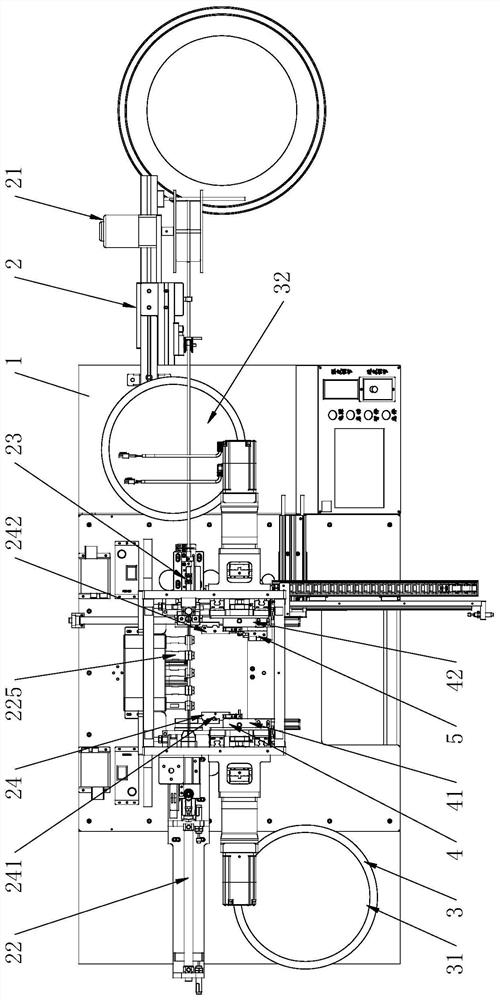

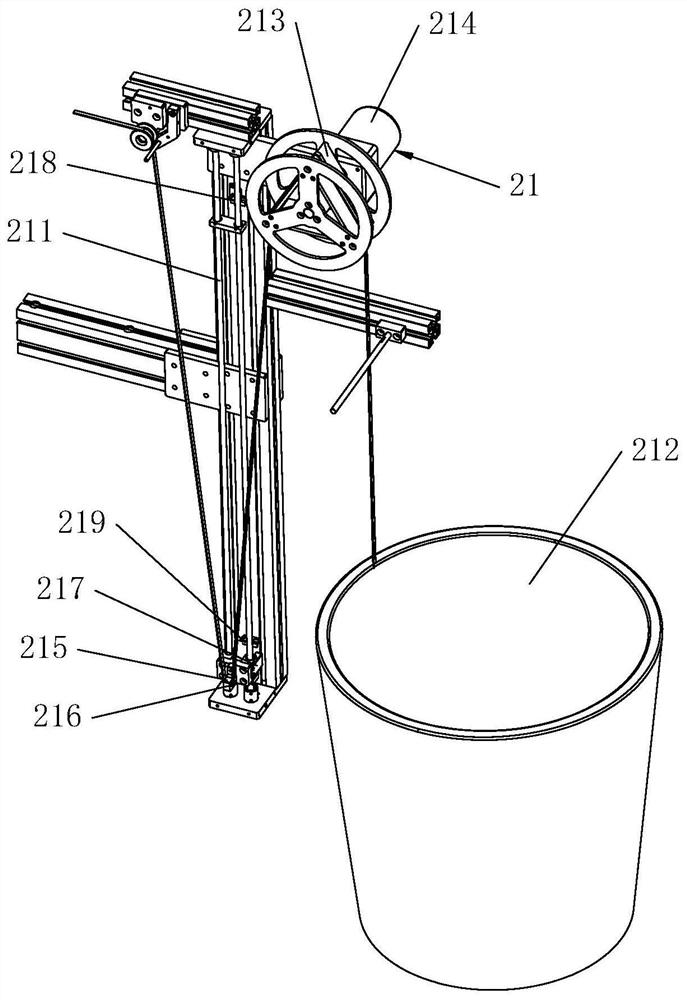

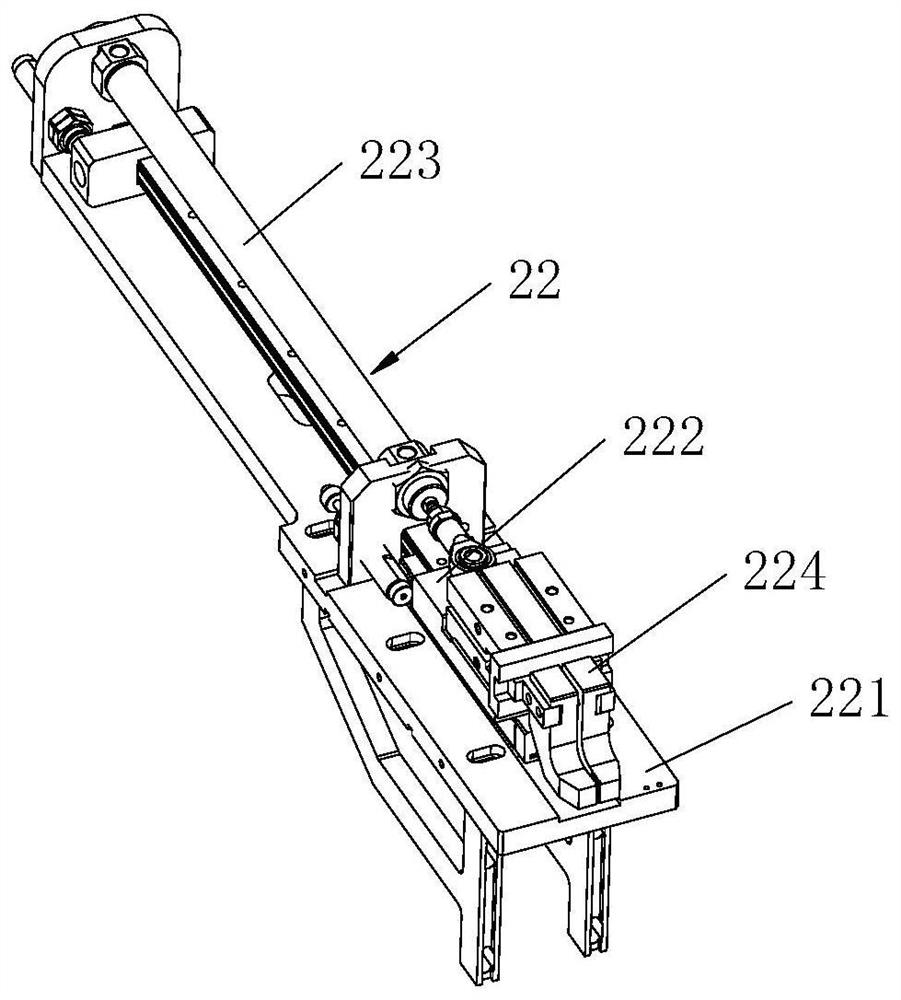

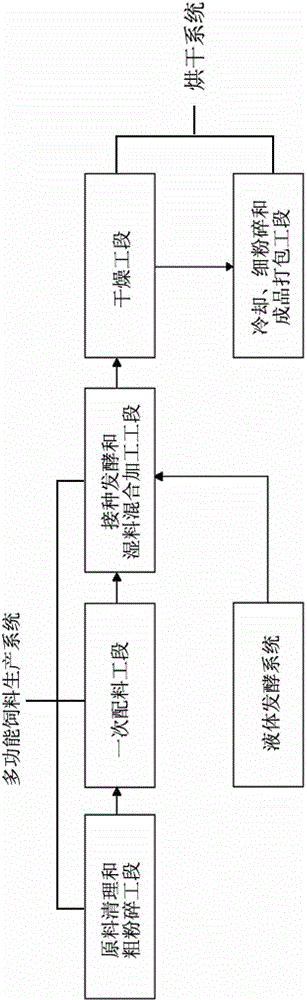

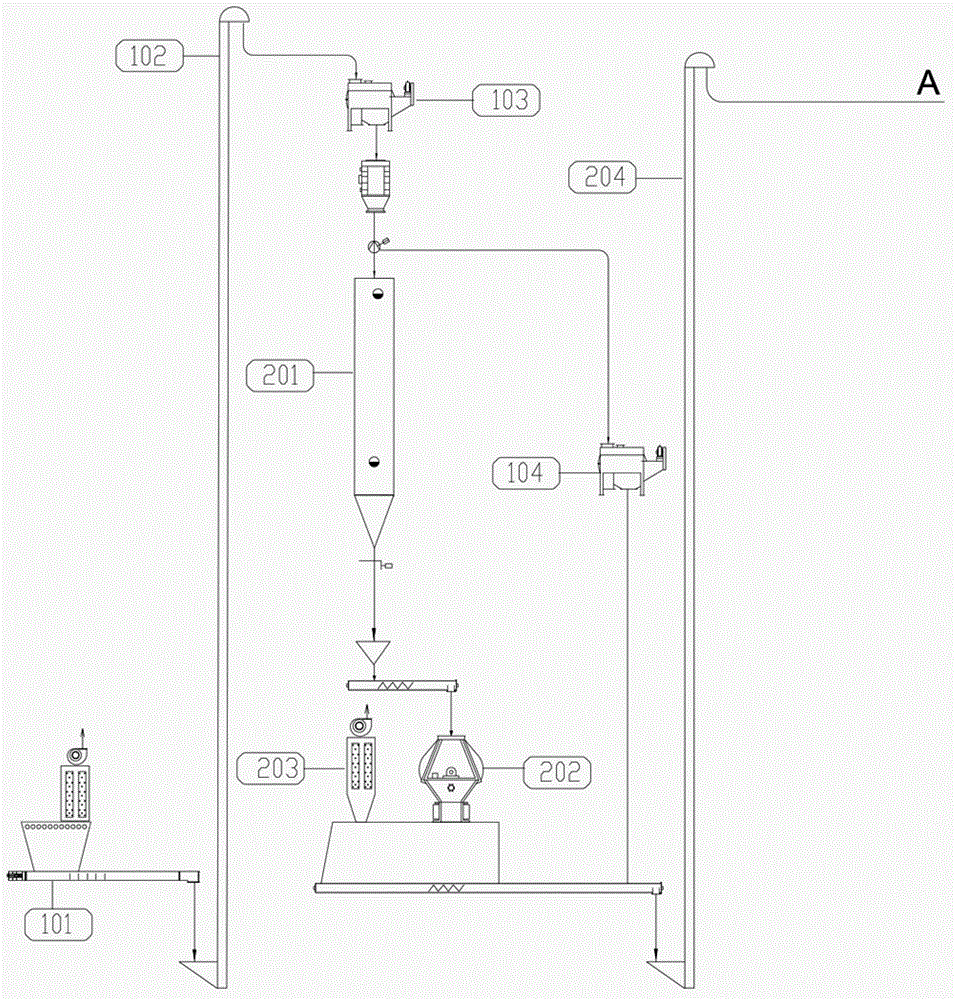

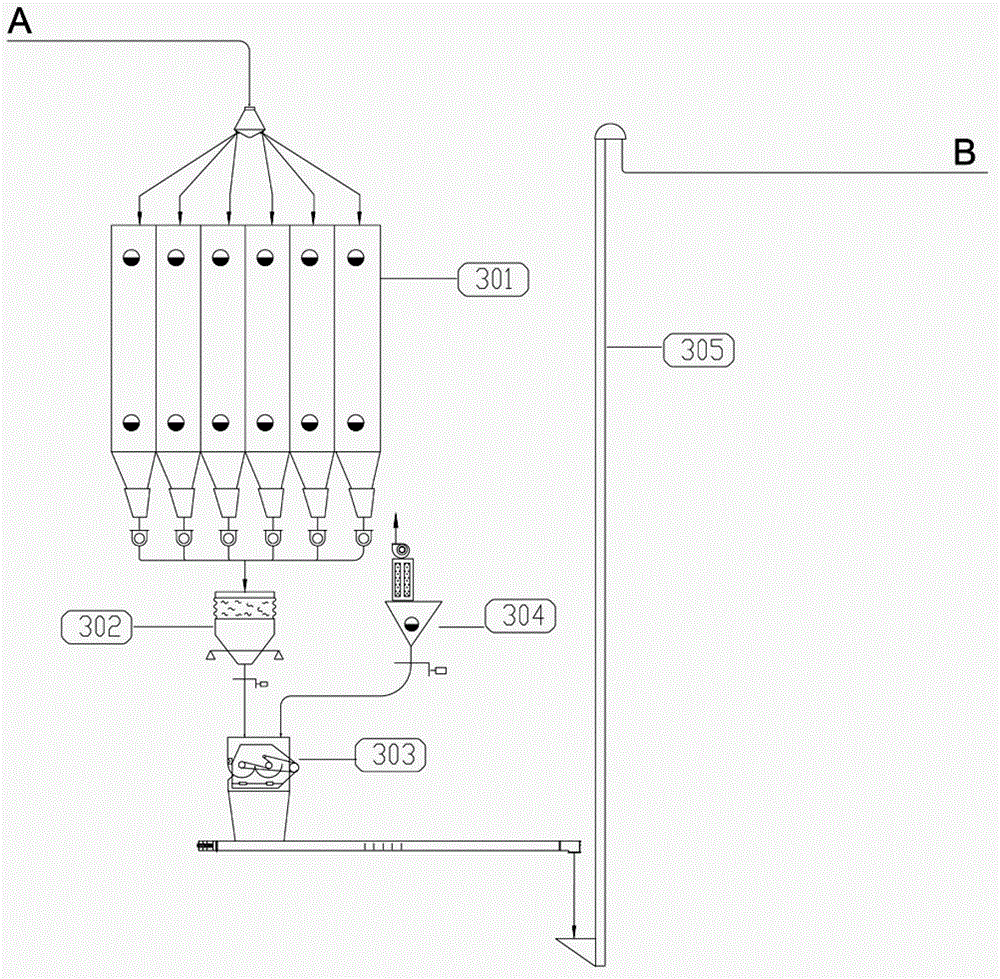

Production device and method of biological feeds

ActiveCN103126042ARealize continuous mass productionPrevent rustFeeding-stuffWork performanceAutomation

The invention provides a production device of biological feeds. The production device is composed of a multifunctional feed production system, a liquid fermentation system and a drying system, the multifunctional feed production system further comprises a raw material clearing and coarse grinding working section, a primary burdening working section and an inoculation fermentation and wet material mixing production working section, and the drying system further comprises a drying working section and a cooling, refine smashing and end product packing working section. The feed production device and a method are high in automation and mechanization degree, stable in working performance, high in work efficiency and simple and convenient to operate and achieve industrialization and large-scale production of probiotic fermented feeds.

Owner:张有聪

Propiconazol disinfectant

The present invention relates to a propiconazol water soluble emulsion fungicide, in which the weight content of the propiconazol is 5-25%.

Owner:周耀德

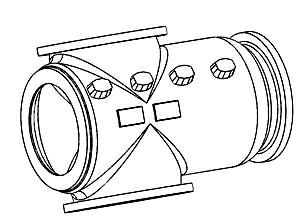

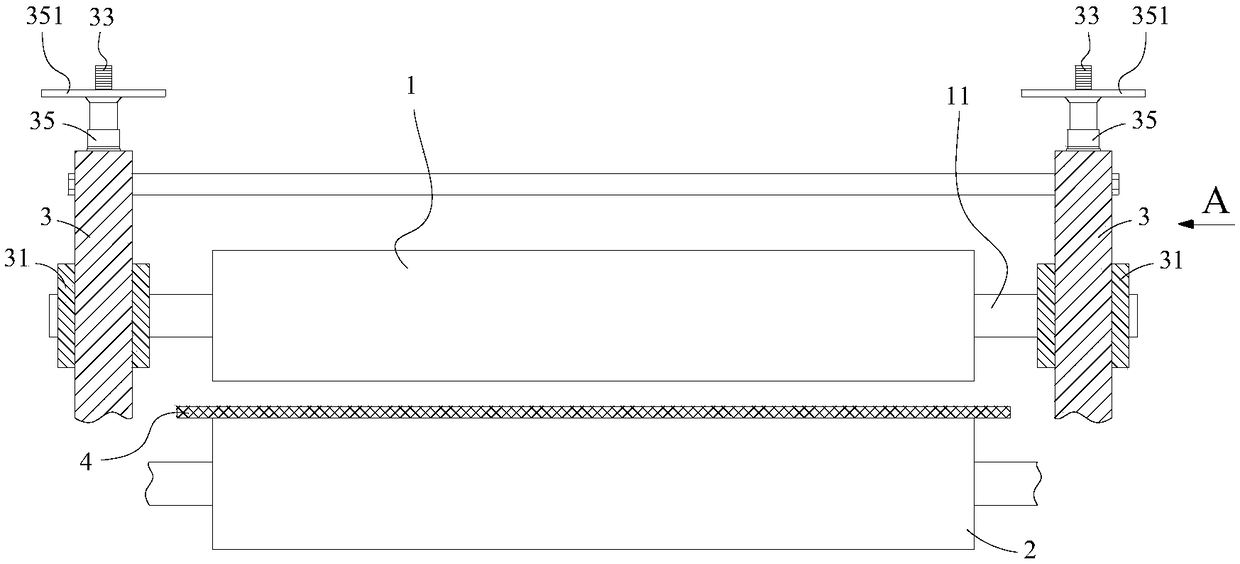

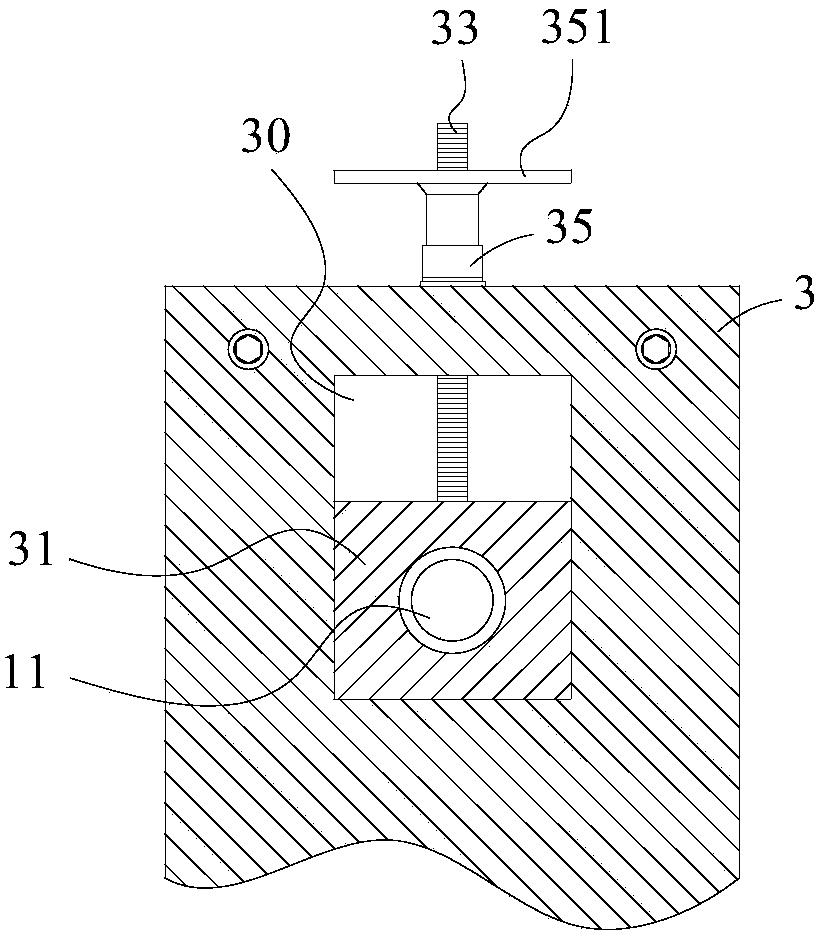

Method for controlling quality of castings obtained through low pressure casting and dynamic pressure detecting device thereof

InactiveCN102554184AProduction applicableReduce manufacturing costFluid pressure measurementMold fillingControl quality

The invention relates to a method for controlling the quality of castings obtained through low pressure casting and a dynamic pressure detecting device thereof. During mold filling, a pressure chamber of a low pressure casting holding furnace is inflated according to the requirements of low pressure casting, so as to input pressure to the pressure chamber, and the real time pressure of the pressure chamber is P0; during the mold filling process, real time pressure P1 of the pressure chamber of the low pressure casting holding furnace is read in a real time manner by utilizing the dynamic pressure detecting device; the real time pressure P1 is compared with the real time pressure P0; if the real time pressure P1 is within a pressure fluctuation range, mold filling is continuously conducted; and if the real time pressure P1 is beyond the pressure fluctuation range, mold filling is immediately stopped. By using the dynamic pressure detecting method provided by the invention, abnormal changes of the pressure in the pressure chamber under production anomaly circumstances can be timely measured, whether the metal liquid mold filling state is abnormal or not in the low pressure casting production process can be judged, the production process can be timely interrupted, and whether problems exist in the sealing performance, the moisture of molding sand and the breathability of the molding sand are detected by taking measures. Metal is saved, the production cost is reduced, and the method and the dynamic pressure detecting device thereof are particularly suitable for the production of large-scale low pressure castings.

Owner:NANTONG L S LIGHT METAL FORMING

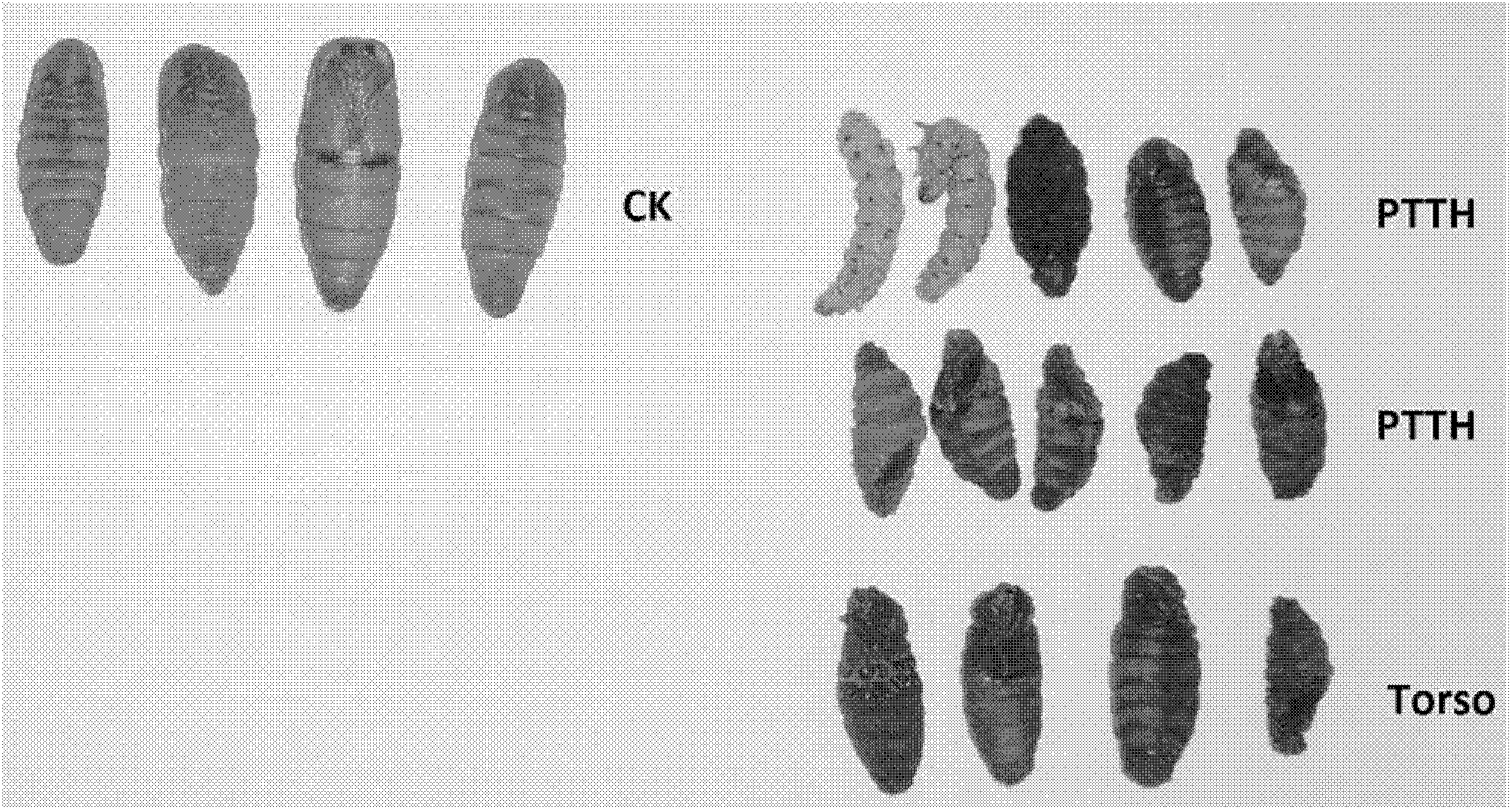

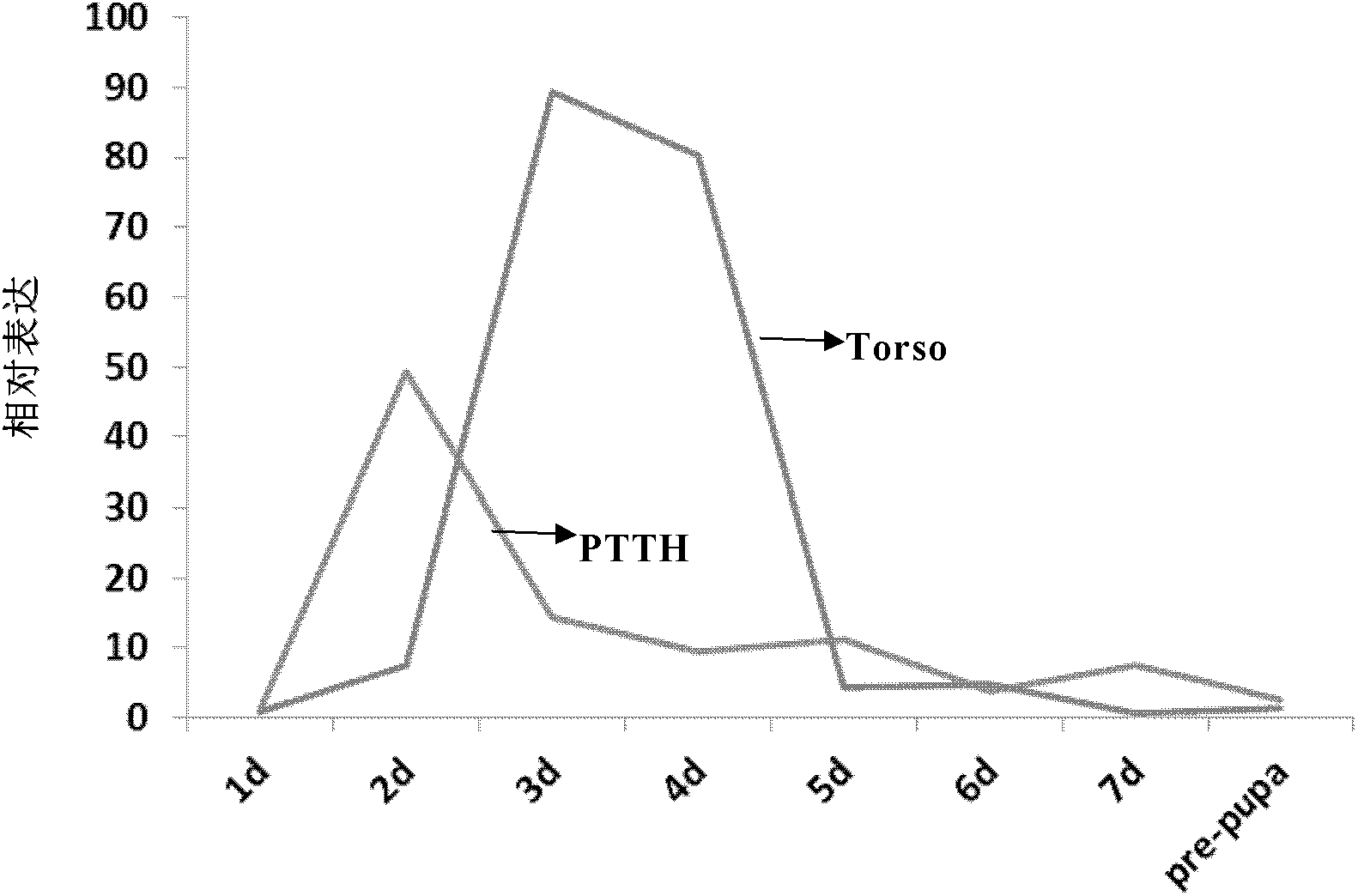

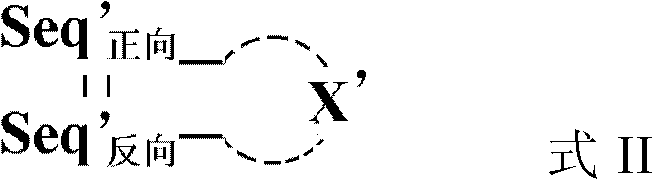

RNAi used for regulating and controlling growth of silkworm pupae and application

InactiveCN103215266AImprove efficiencyEasy to useVector-based foreign material introductionDNA preparationOrder LepidopteraSericulture

The invention relates to RNAi used for regulating and controlling growth of silkworm pupae and an application. Concretely, the invention discloses two gene segments based on the death of silkworm pupae due to a RNA interference technology, a composition containing dsRNA is sprayed on folium mori for feeding silkworm, so that the silkworm can be grown up at larval period and died at pupal period. The method is convenient, fast and accurate, can solve the problems of energy consumption and decreased silk quality due to cocoon drying treatment in sericulture industry, and provides references for preventing and controlling lepidoptera pests.

Owner:SHANGHAI INST OF BIOLOGICAL SCI CHINESE ACAD OF SCI

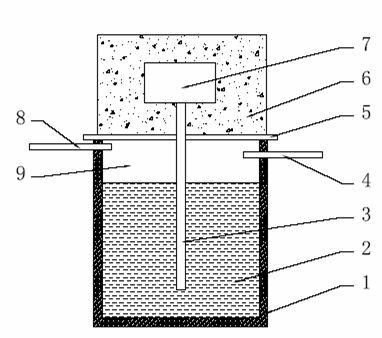

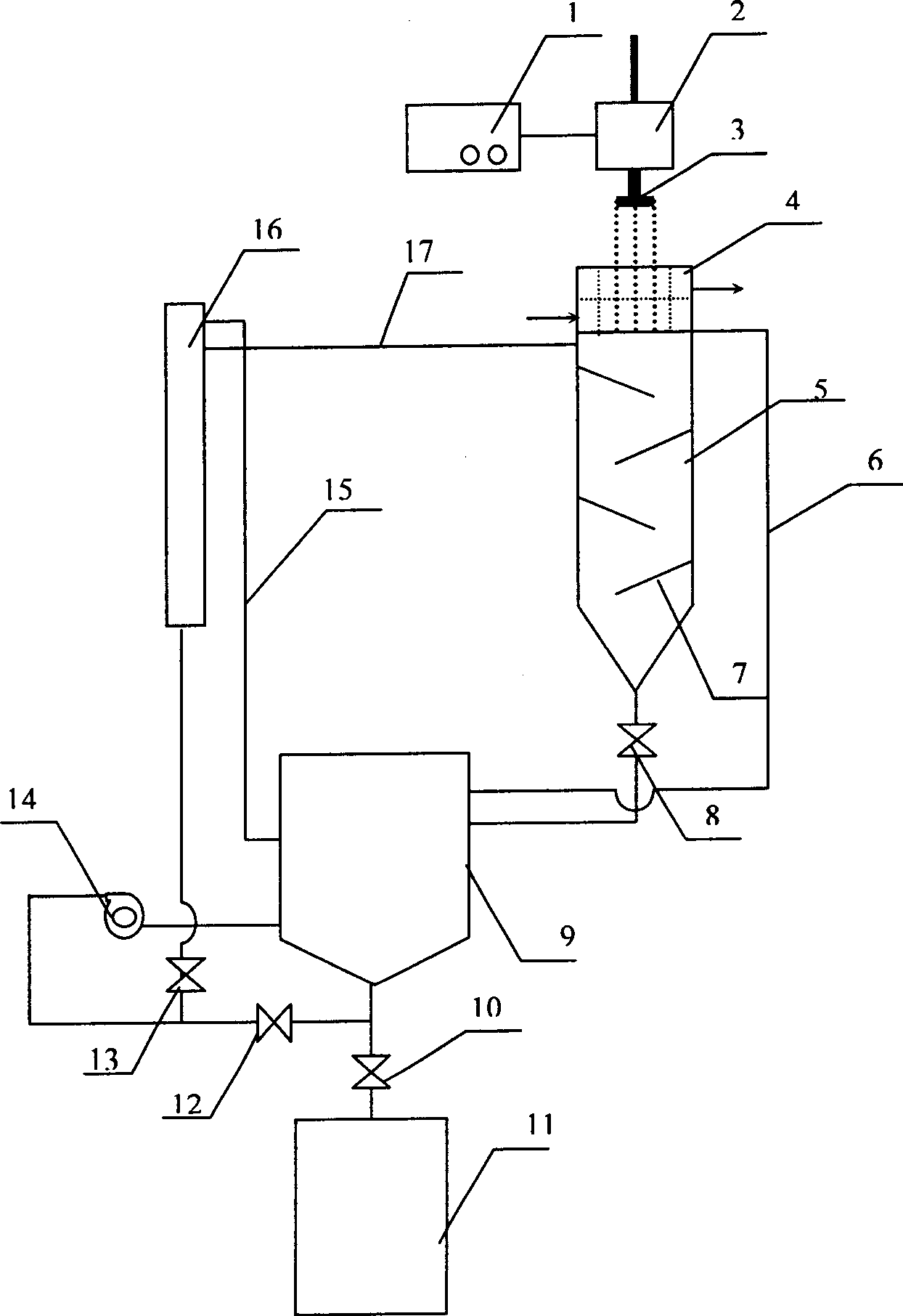

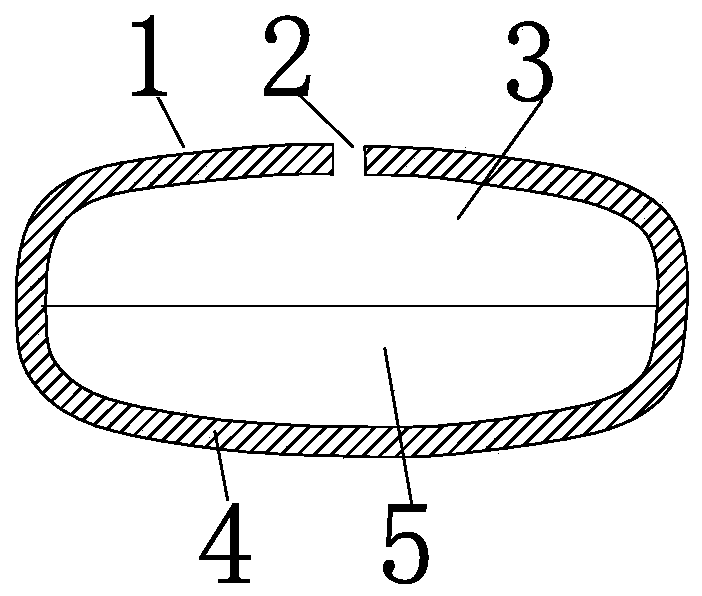

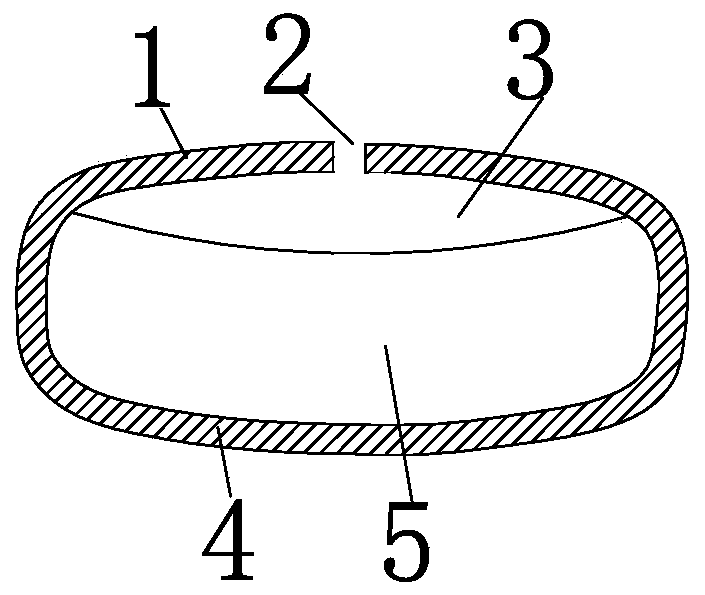

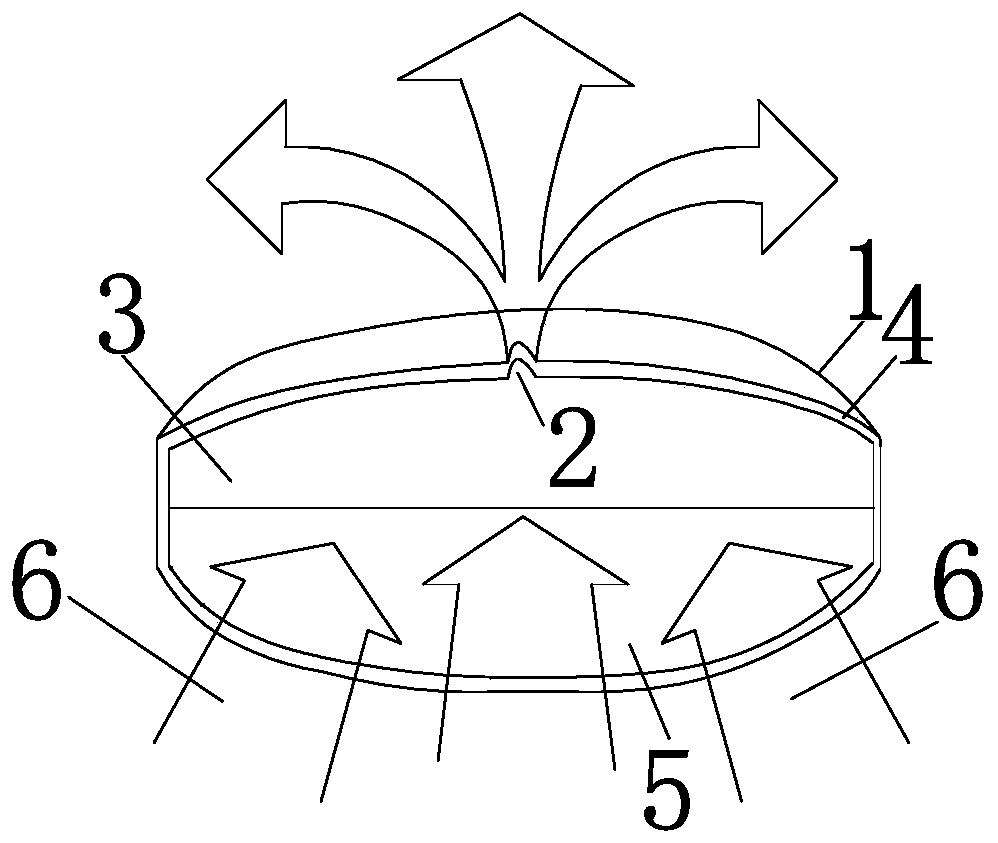

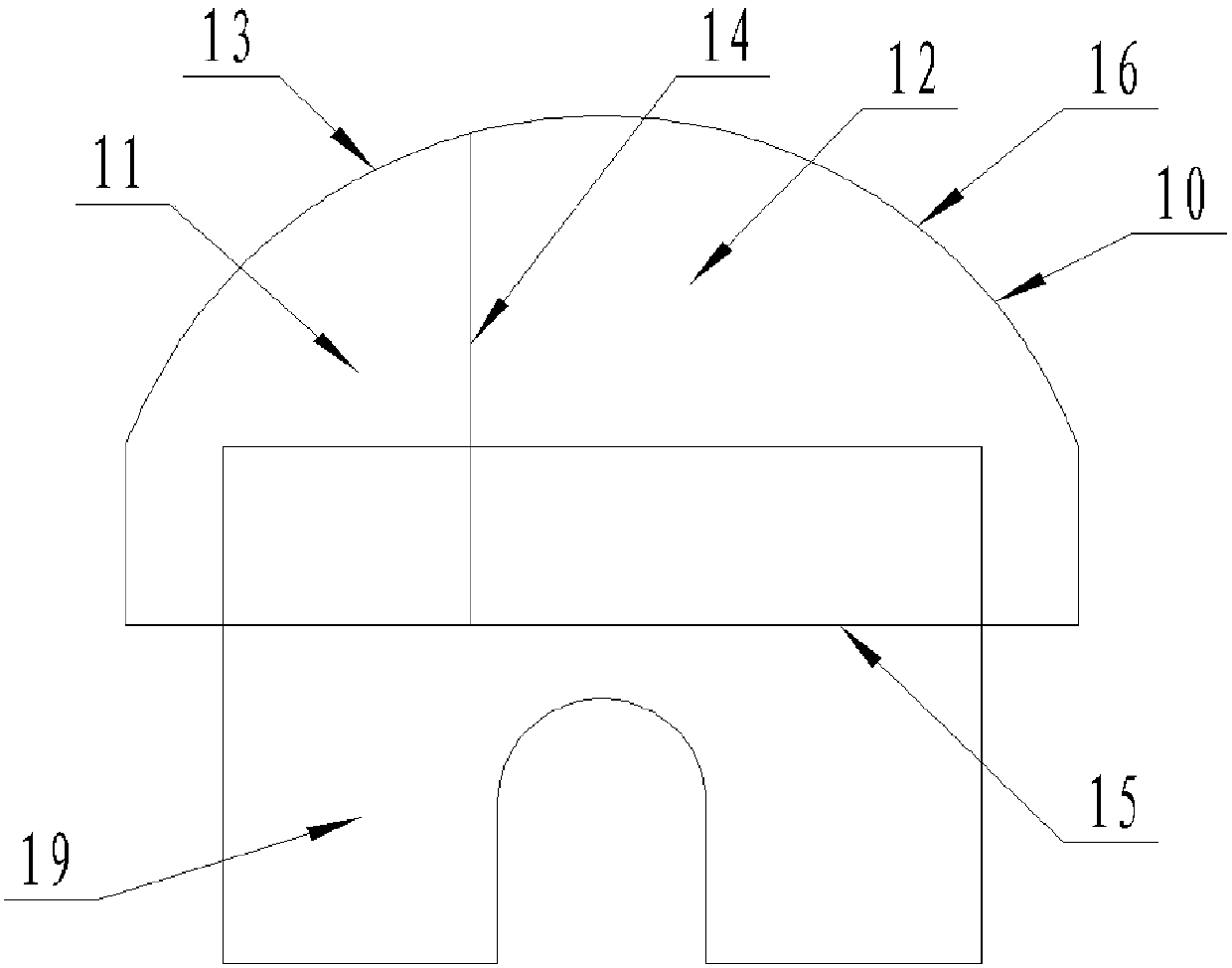

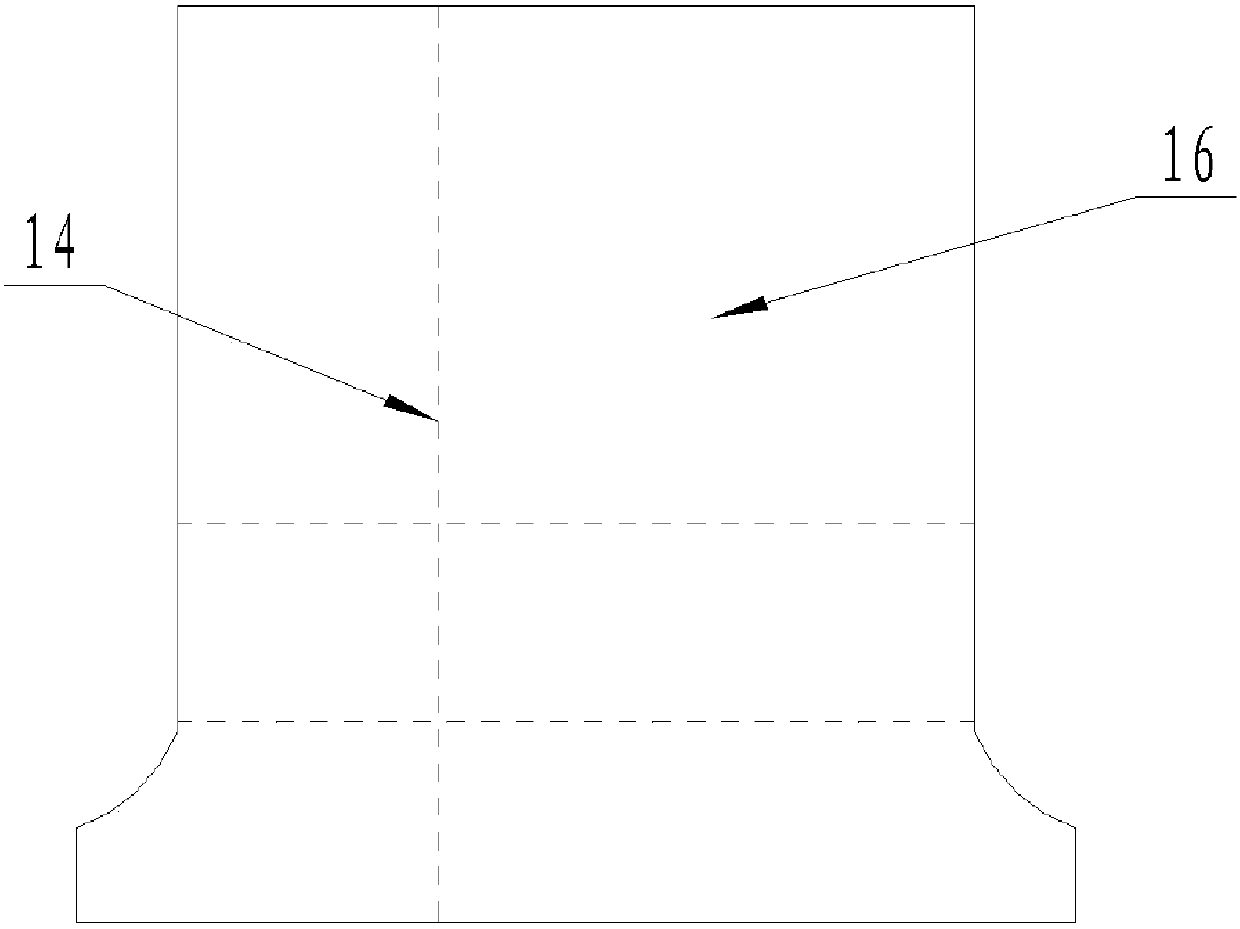

System for preparing gel bead

ActiveCN1843610AFull gelExtended stayNuclear energy generationGranulation by liquid drop formationEngineeringAmmonia

The invention relates to a system for preparing gel ball, belonging to the technique that preparing ceramic gel ball. Said system comprises two parts as vibration dispersion system and gel system. Wherein, the vibration dispersion system comprises a signal controller 1, a vibrator 2, and an ejector; the gel system comprises a ammonia distributing ring 4, a gel post 5, a liquid groove 9, a baffle post 16, and a ball storage pot 11. The liquid of gel via cycle pump 14 can be cycled between the gel post 5, the liquid groove 9, and the baffle post 16; the sol via the ammonia distributing ring 4 is gelled into gel ball in the gel post 5; and the gel ball will flow into liquid groove 9 with liquid. Said system can confirm full gelling on the sol ball and reduce the pressure between gel balls, to avoid the distribution of flowing medium liquid on the liquid level. And it has simple operation and the application for continuous operation.

Owner:TSINGHUA UNIV

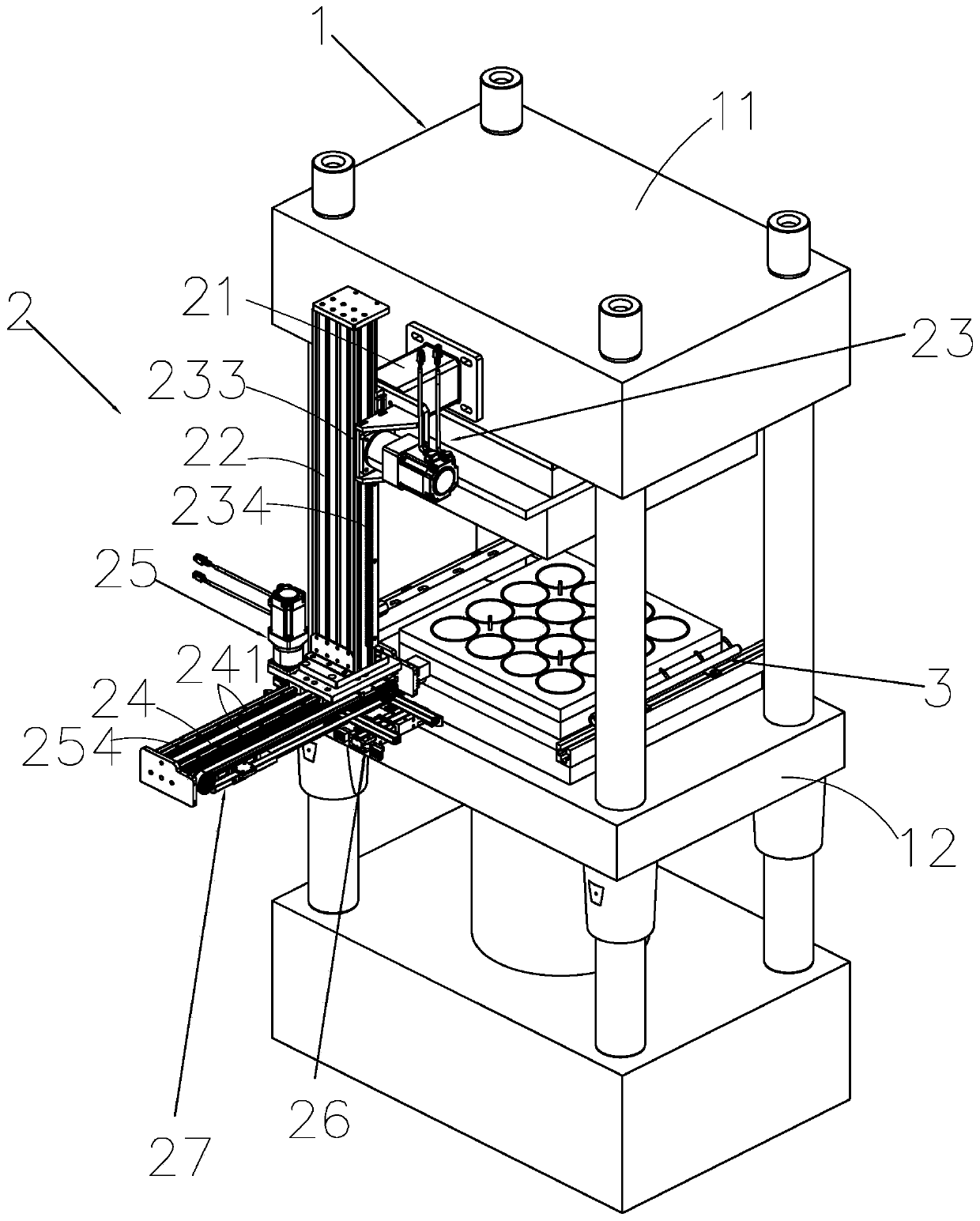

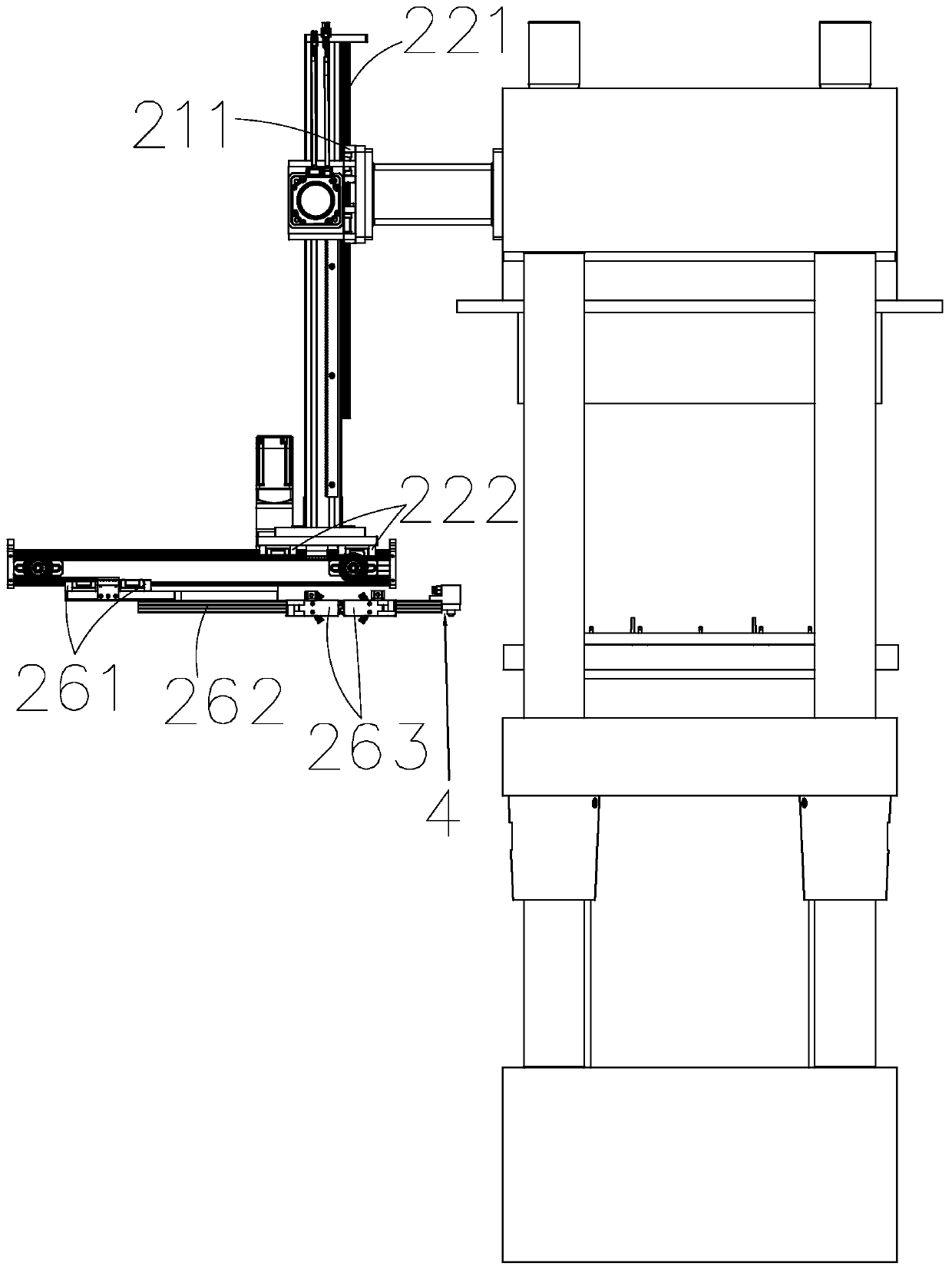

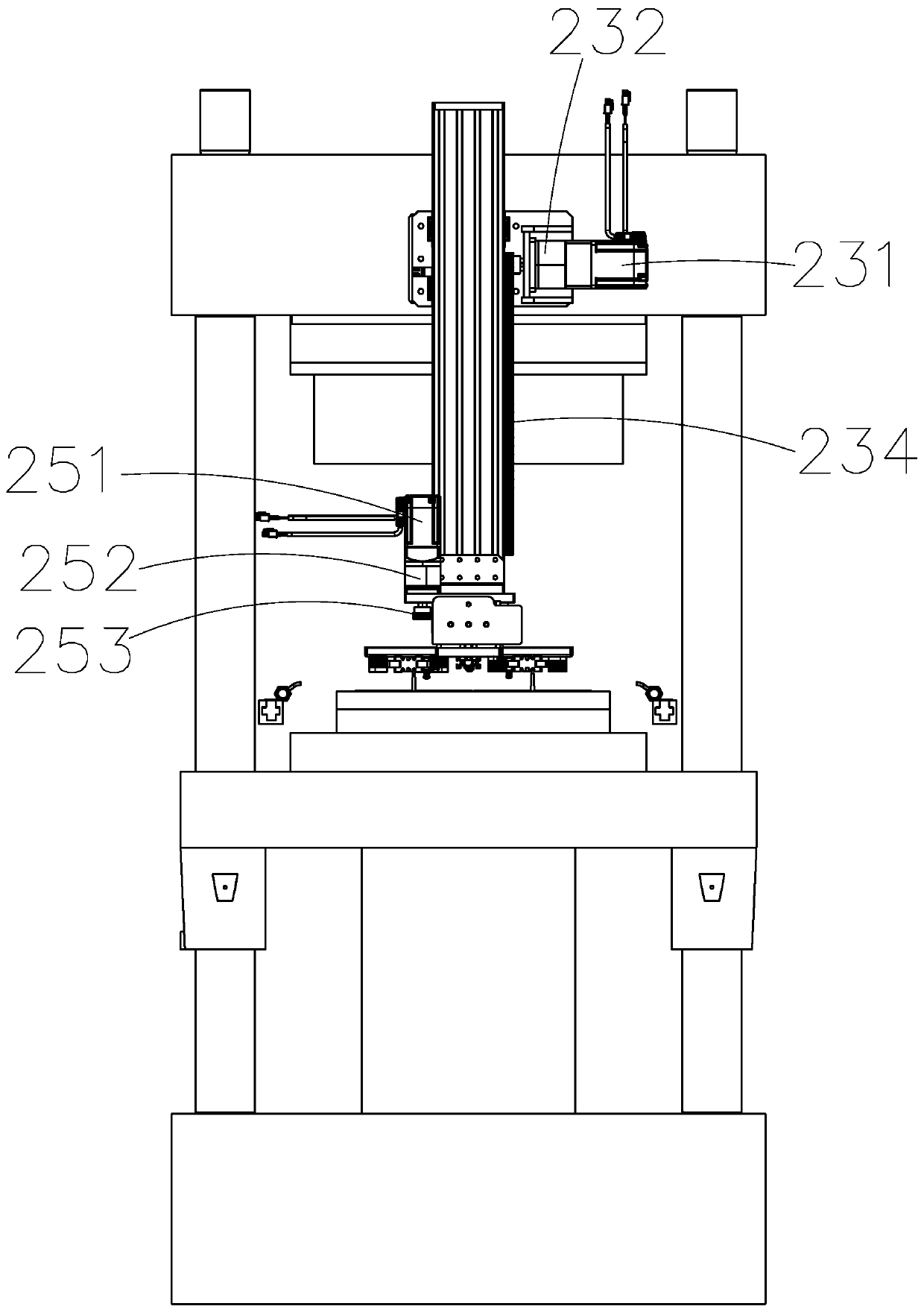

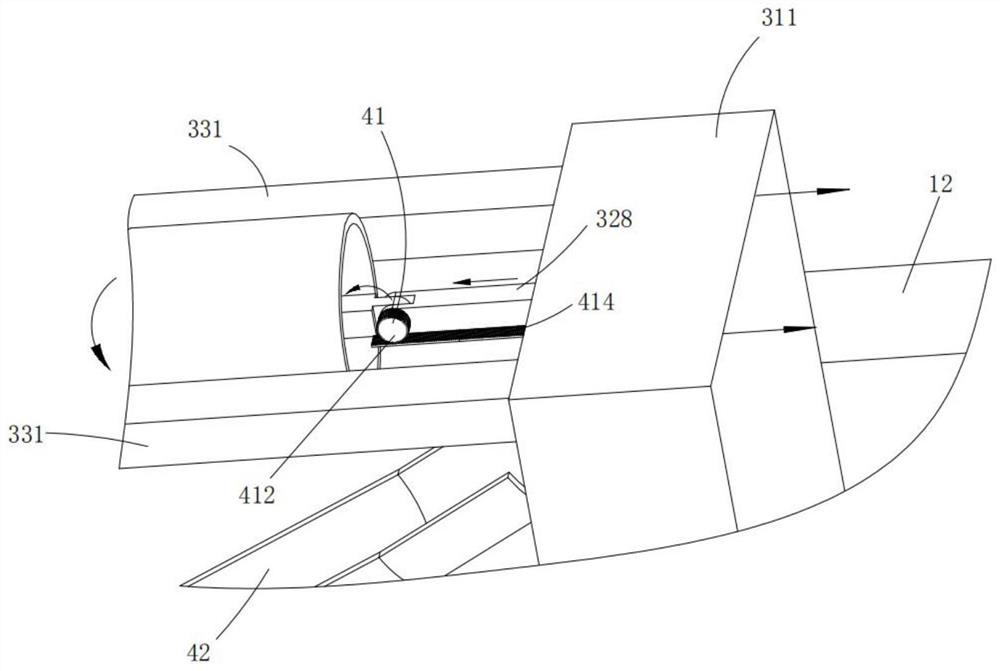

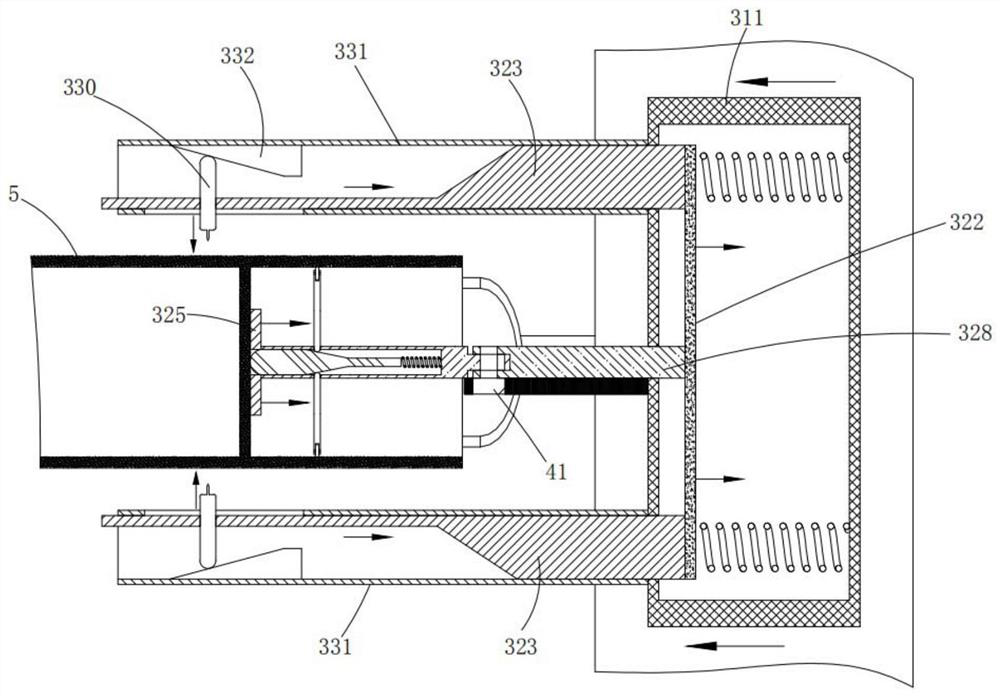

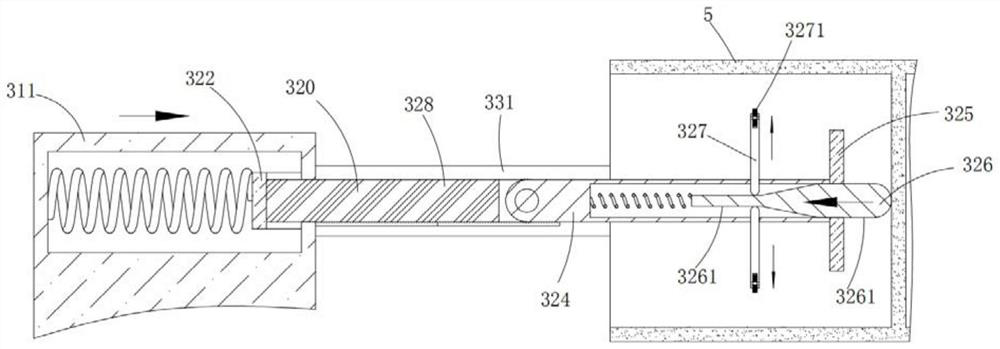

Automatic production device

The invention relates to an automatic production device which comprises a mold having a mold opening state and a mold closing state and a material taking mechanism capable of taking out a product formed in the mold. The material taking mechanism comprises a fixing base fixedly installed on the mold, a first main beam capable of sliding relative to the fixing base in the up-down direction, a firstdriving assembly used for driving the first main beam to slide relative to the fixing base, a second main beam capable of sliding relative to the first main beam in the left-right direction, a seconddriving assembly used for driving the second main beam to slide relative to the first main beam, a clamping assembly used for clamping a product and a linkage assembly connected with the first main beam and the clamping assembly and enabling the clamping assembly to slide relative to the second main beam when the second main beam slides relative to the first main beam, and the linkage assembly isinstalled on the second main beam. The automatic production device can achieve unmanned production, reduces manual labor, improves production efficiency and production safety, and is particularly suitable for production of rubber products.

Owner:昆山佳龙科智能科技有限公司

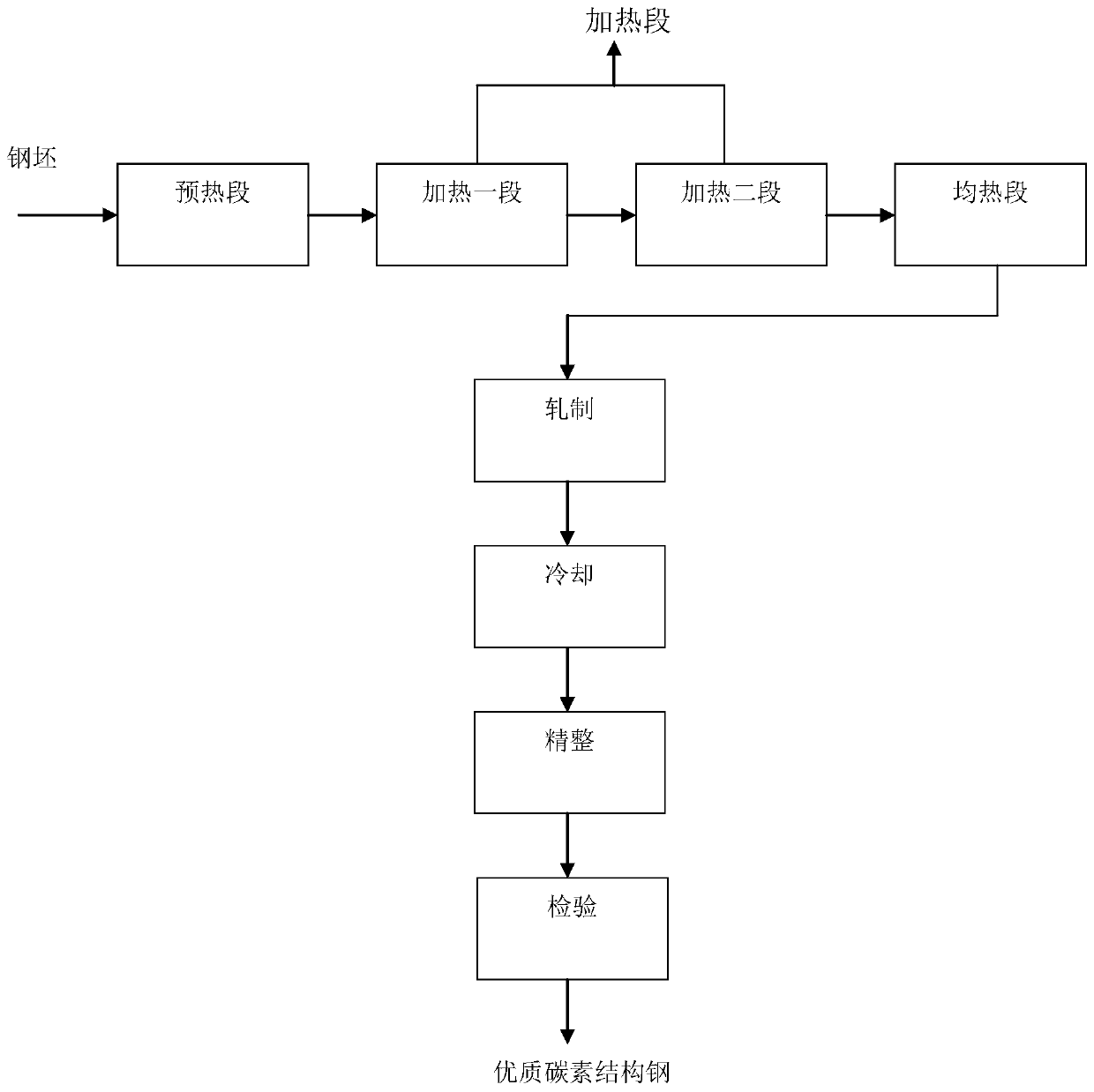

Hot rolling process for quality carbon structural steel

InactiveCN111530942APrevent grain coarseningAvoid increased rolling forceTemperature control deviceWork cooling devicesBrinellingPearlite

The invention provides a hot rolling process for quality carbon structural steel. Procedures of preheating, heating, soaking, rolling, cooling, finishing and inspection are adopted, the temperature ofa heating section is controlled to be 1060 to 1250 DEG C, and the temperature of a soaking section is controlled to be 1040 to 1240 DEG C, so as to prevent the temperature of the heating section andsoaking section from being too low, resulting in increasing the rolling force and making overload of the rolling mill, and to reduce the risk of equipment damage; the temperature of final rolling is controlled to be 900 to 950 DEG C to make the temperature of final rolling close to a phase transformation point, the transformation rate of undercooled austenite to pearlite with ferrite is accelerated such that the Brinell hardness of the quality carbon structural steel is reduced, and the phenomenon that cracks are prone to occur in the subsequent cold shearing process is improved; and billet composition, cooling method, crimping temperature and other methods are controlled to further reduce the occurrence of edge cracks in the production process of carbon structural steel. The hot rolling process for quality carbon structural steel has low control difficulty, strong operability, simple method, no need for high-cost transformation of controlled cooling process, and low cost, and can be applied to the production of various specifications of quality carbon structural steel.

Owner:江苏联峰实业有限公司

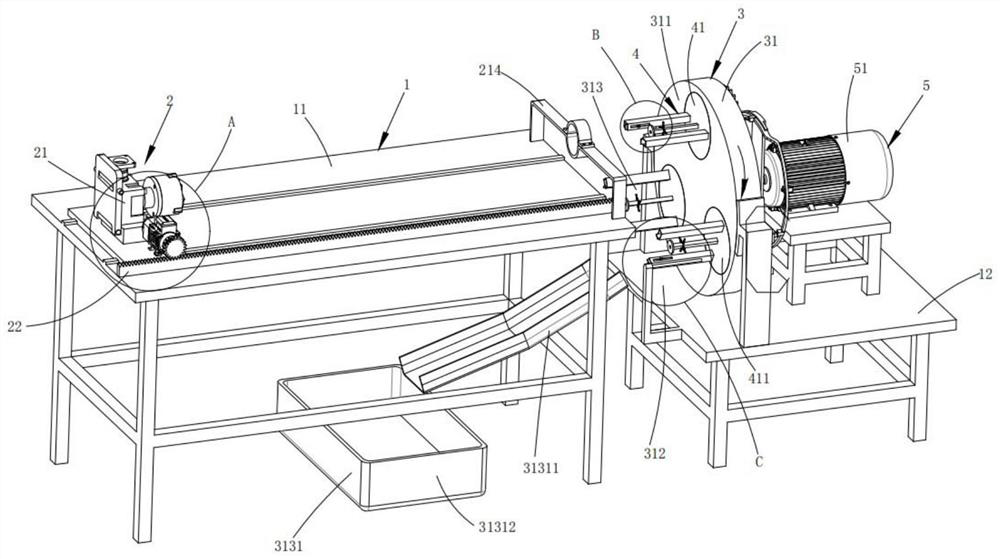

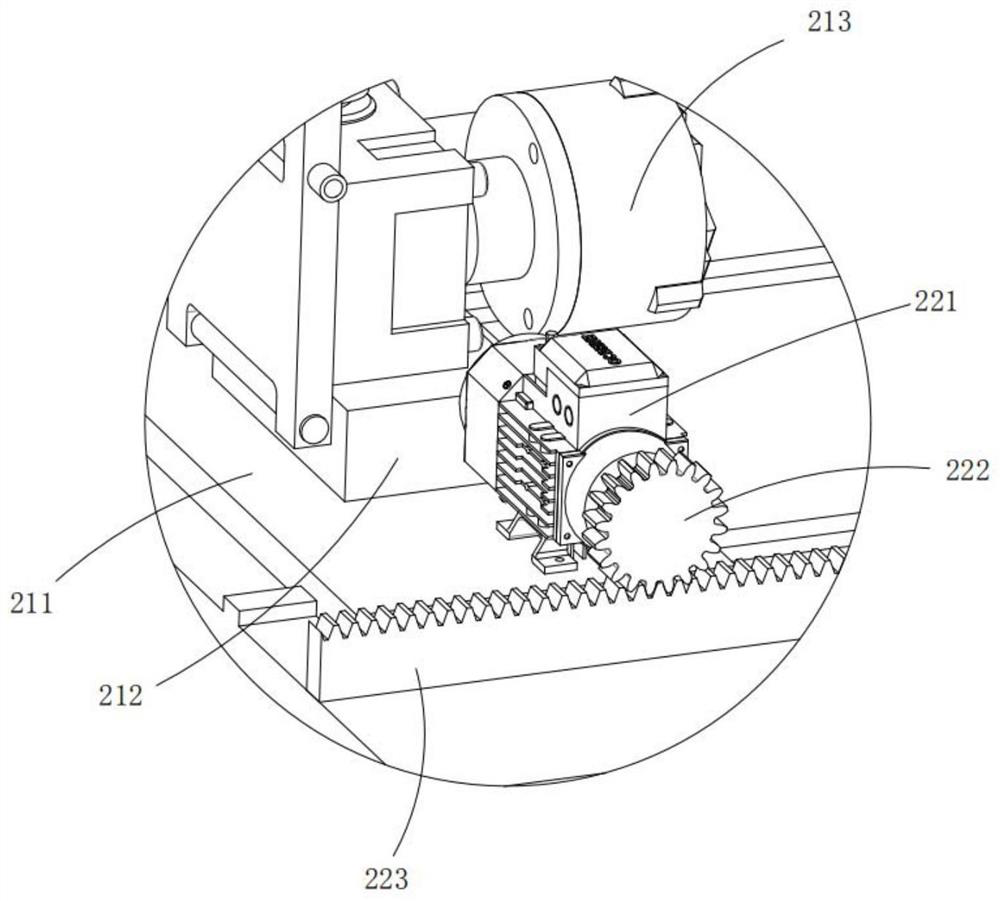

Bamboo pen barrel primary processing equipment

InactiveCN111805653AIncrease productivityFast blankingCane mechanical workingProfiling/shaping machinesEngineeringMechanical engineering

The invention provides bamboo pen barrel primary processing equipment. The bamboo pen barrel primary processing equipment comprises a worktable, a feeding device, a cutting device and a material receiving device, wherein the worktable comprises a main worktable and an auxiliary worktable; the feeding device comprises a fixing assembly, a power assembly and a grinding assembly; the cutting device comprises a moving assembly, a positioning assembly and a cutter assembly, and the positioning assembly comprises an installation assembly and a supporting assembly; the cutter assembly comprises a cutting head; and the material receiving device comprises a control assembly. According to the bamboo pen barrel primary processing equipment, the feeding device drives a bamboo tube to move and rotate,a supporting assembly can extend into the bamboo tube, the supporting assembly can rotate under the action of a control assembly, after the supporting assembly is in contact with a bamboo joint, the movement of the moving assembly make the cutting head abut against the outer wall of the bamboo tube, the bamboo tube rotates the cutter assembly to cut the bamboo tube and retain the bamboo joint, then the moving assembly exits, the control assembly drives the supporting assembly for discharging, and the technical problems of low production efficiency of pen barrels caused by manual cutting and stacking of the pen barrels in the prior art are solved.

Owner:临泉县金钉子生产力促进中心有限公司

Preparation method for preparing capsules by using modified soy protein

InactiveCN104368008AGood water solubilityImprove water holding capacityCapsule deliveryMacromolecular non-active ingredientsBiotechnologyNutritive values

The invention discloses a preparation method for preparing capsules by using modified soy protein. The method comprises the following steps: preparing soy protein and modifying the protein. According to the method, the water solubility, water binding capacity, gel property and viscosity of vegetable proteins are improved by virtue of chemical modification, cross-linking between polyhydroxy compounds and proteins and interactions between transglutaminase and the soy protein, and the aim of replacing gelatin by using the modified soy protein so as to produce medical capsules is achieved. The series of products are high in nutritive values, green, environmentally friendly, non-toxic and pollution-free, and some infectious diseases caused by animal gelatin can be avoided. Meanwhile, the method disclosed by the invention has the characteristics of simplicity and convenience in operation, low cost and simplicity in control.

Owner:ANHUI UNIVERSITY

Double-chamber osmotic pump type glipizide controlled release tablet and industrial production method

InactiveCN110368372AGood compatibilityReduce investmentSulfonylurea active ingredientsPharmaceutical non-active ingredientsOrganic solventPunching

The invention belongs to the technical field of glipizide controlled release tablets, and particularly relates to a double-chamber osmotic pump type glipizide controlled release tablet and an industrial production method. The double-chamber osmotic pump type glipizide controlled release tablet consists of a drug layer, a propelling layer, a rigid semi-permeable membrane, a drug release small holeand a moisture-proof layer; the drug layer takes polyethylene glycol 6000 as a carrier, granulation is carried out by a hot melting method, an organic solvent is not used, and low-power laser round punching is carried out to prepare the double-chamber osmotic pump type glipizide controlled release tablet. The double-chamber osmotic pump type glipizide controlled release tablet and the industrial production method have the advantages of simple granulation process, less equipment investment, high production efficiency, low energy consumption and suitability for industrial production. The produced controlled release tablet is good in stability and convenient to store and transport; organic solvent residues are completely avoided in a granulation process; in a double-layer tabletting process,the technical problem of color mixing is solved, the requirement on equipment performance is lowered, and the service life of the equipment is prolonged.

Owner:淄博万杰制药有限公司

System for preparing gel bead

ActiveCN100371064CRelieve pressureReduce distortionNuclear energy generationGranulation by liquid drop formationEngineeringAmmonia

The invention relates to a system for preparing gel ball, belonging to the technique that preparing ceramic gel ball. Said system comprises two parts as vibration dispersion system and gel system. Wherein, the vibration dispersion system comprises a signal controller 1, a vibrator 2, and an ejector; the gel system comprises a ammonia distributing ring 4, a gel post 5, a liquid groove 9, a baffle post 16, and a ball storage pot 11. The liquid of gel via cycle pump 14 can be cycled between the gel post 5, the liquid groove 9, and the baffle post 16; the sol via the ammonia distributing ring 4 is gelled into gel ball in the gel post 5; and the gel ball will flow into liquid groove 9 with liquid. Said system can confirm full gelling on the sol ball and reduce the pressure between gel balls, to avoid the distribution of flowing medium liquid on the liquid level. And it has simple operation and the application for continuous operation.

Owner:TSINGHUA UNIV

Electrostatic film product and production process thereof

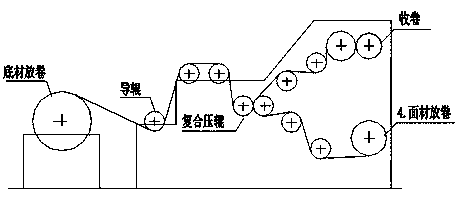

InactiveCN110039870ASimple structureChange thicknessSynthetic resin layered productsLaminationBiochemical engineeringPaper sheet

The invention relates to an electrostatic film product and a production process thereof. The electrostatic film product comprises two-side offset paper, wherein a glue layer is arranged on one side ofthe two-side offset paper, a BOPP film is arranged on one side of the glue layer, and electrostatic film fabric is arranged on one side of the BOPP film; the BOPP film is placed on a winding roller on a coating machine, paper is introduced through the roller, and acrylic glue is evenly applied to the side with low surface tension of the BOPP film through a coating scraper; the BOPP film is introduced into an oven at 60-80 DEG C for 20-25 seconds by a drive guide roller, then the acrylic glue is dried and then taken out of the oven to be combined and glued with the two-side offset paper, and electrostatic film backing paper is formed; the manufactured electrostatic film backing paper is subjected to rewinding, defective products are removed, the rewound paper is arranged orderly on a special compound machine to compound the electrostatic film fabric with the BOPP film side of the electrostatic film backing paper, and then winding and packaging are performed. The product has the advantages of simple structure, high gluing speed, stable glue thickness, convenient operation and the like, production benefits can be greatly increased, and glue thickness can be adjusted.

Owner:LECCO KAIPING ADHESIVE PROD

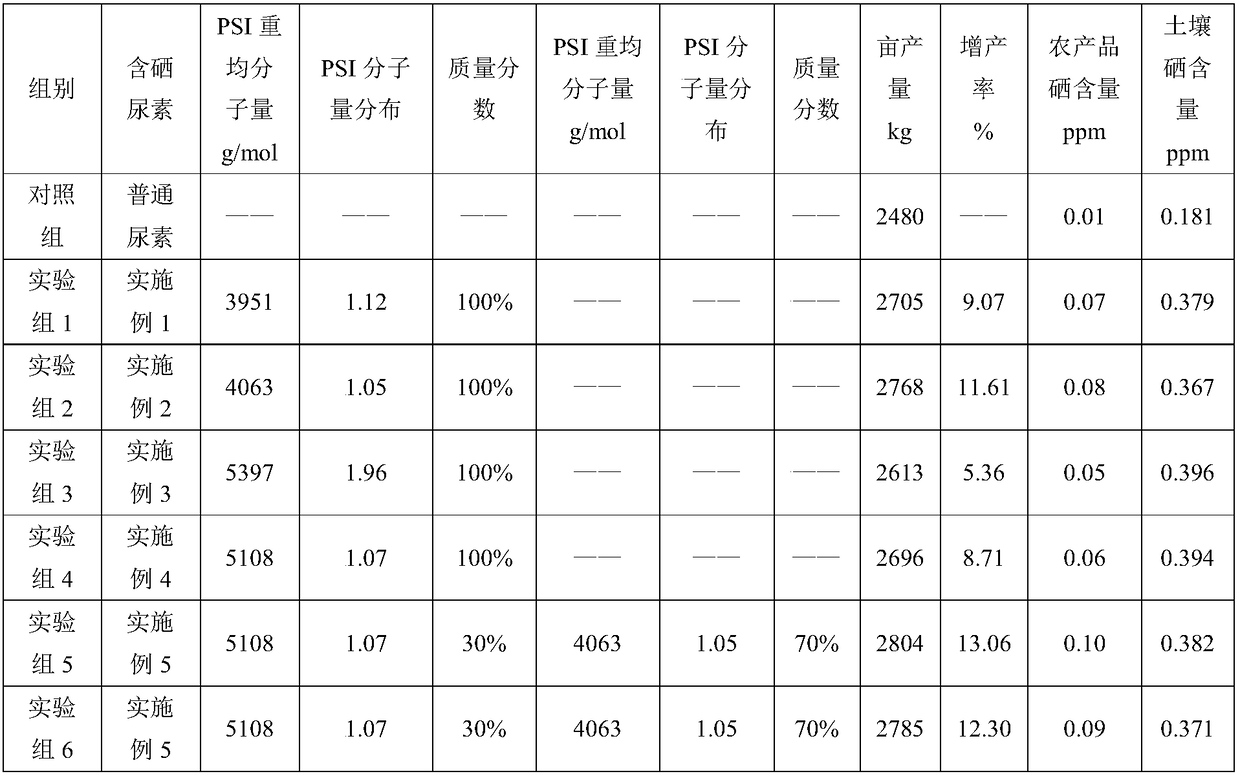

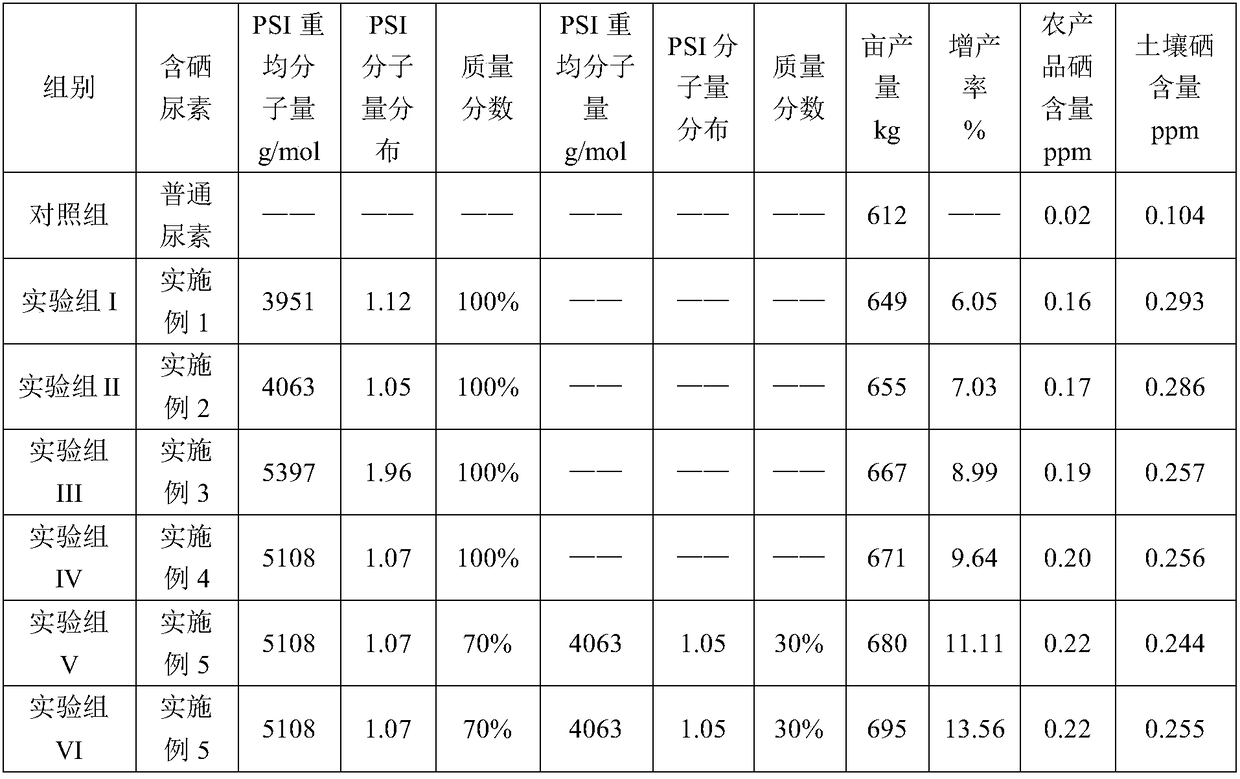

Organic chelate selenium fertilizer synergist and preparation method and application thereof

ActiveCN108503469ALow toxicityIncrease profitFertilising methodsOrganic fertilisersWater insolubleInorganic selenium

The invention relates to an organic chelate selenium fertilizer synergist which is prepared from poly-aspartate, organic chelate zinc and organic chelate selenium in a weight ratio of (5-1):(5-20):(3-14), preferably (8-12):(10-15):(6-10). The invention also relates to a method for preparing the synergist, and a fertilizer containing the synergist. According to the invention, inorganic selenium isseparated from organic selenium by ethanol, so as to ensure the content of organic selenium in the fertilizer, and effectively prevent the problem that water insoluble matter is produced by slow chelating of inorganic selenium and poly-aspartate at normal temperature. After the organic chelate selenium is added to the fertilizer, the fertilizer can achieve a non-toxic standard, and after the prepared selenium-containing fertilizer is applied to soil, the residual amount is extremely low, and selenium pollution cannot be caused to the soil, and therefore, the synergist disclosed by the invention can be directly used for single fertilizers and compound fertilizes, and is wide in application scope.

Owner:CHONGQING JIANFENG INDAL GROUP

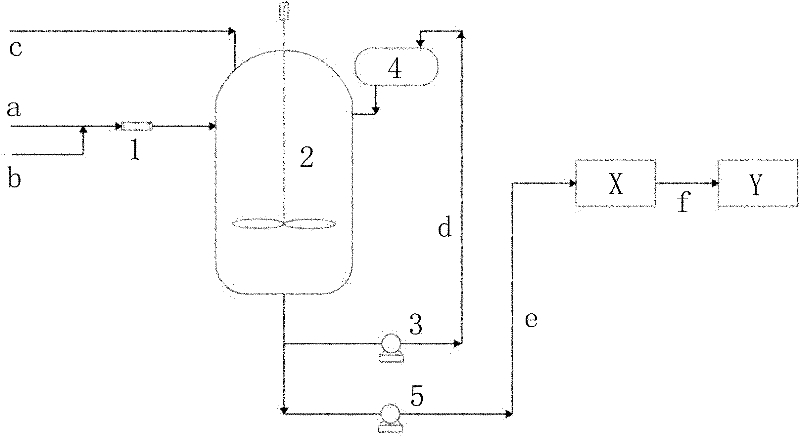

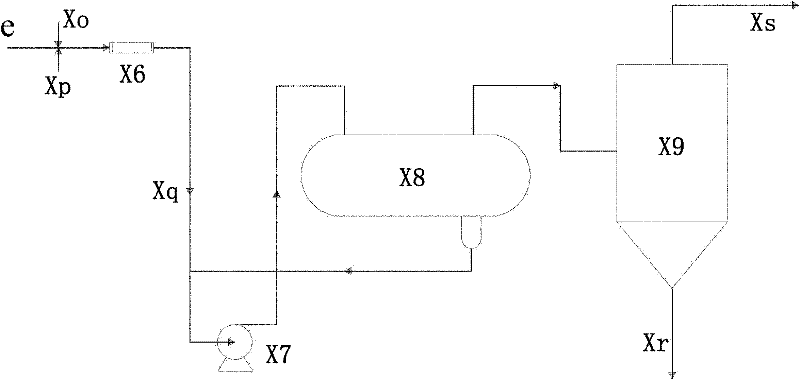

Continuous polymerization production method of petroleum resin

ActiveCN102086252BGuaranteed stabilityThe polymerization process is stablePetroleum resinMixed materials

The invention provides a continuous polymerization production method of petroleum resin. The continuous polymerization production method comprises the following steps: raw materials are pre-mixed in a static mixer, and then continuously enter into a polymerization reaction kettle from a kettle side; a catalyst solution enters into the polymerization reaction kettle continuously from a kettle top;mixed material liquid are stirred in the polymerization reaction kettle to generate polymerization reaction; polymerization material liquid is fed to a condenser for condensation through a circulating pump connected with the kettle bottom, and then the condensed polymerization material liquid returns to the reaction kettle to be polymerized continously; and the polymerization material liquid is continuously extracted by an extraction pump at the kettle bottom and then subjected to posttreatment so as to obtain the petroleum resin product. In the method, the production process especially polymerization reaction is continuously carried out, thus the petroleum resin with good hue and molecule weight is obtained, gelatin and implosion phenomena do not happen, the stability of the product quality can be guaranteed, simultaneously, energy consumption is reduced, and benefits are increased.

Owner:ZIBO LUHUA HONGJIN NEW MATERIAL CO LTD

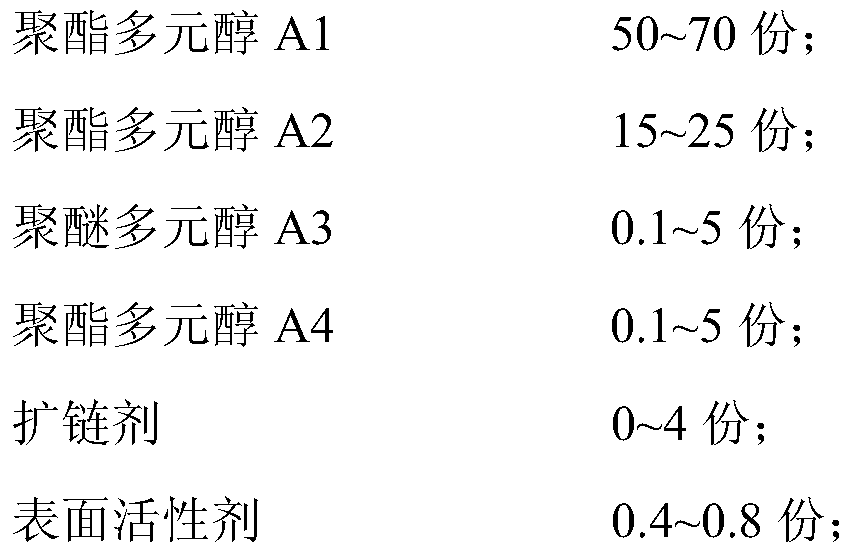

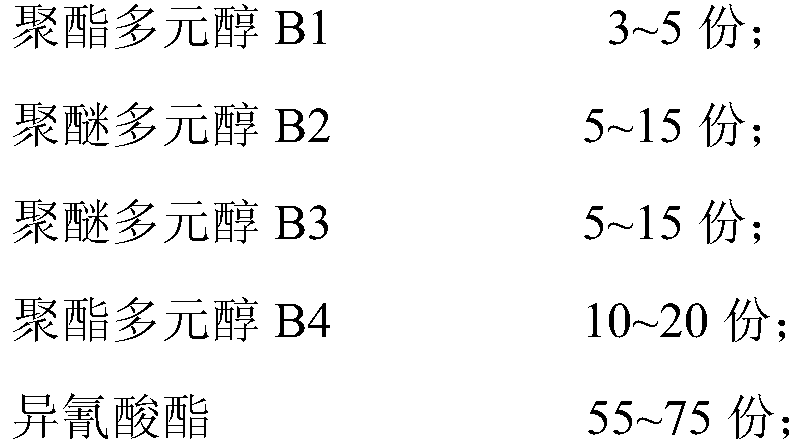

Polyurethane shoe sole stock solution and preparation method thereof

The invention relates to a polyurethane shoe sole stock solution and a preparation method thereof. The polyurethane shoe sole stock solution comprises a component A, a component B and a component C, wherein the component A comprises the raw materials of polyester polyol A1, polyester polyol A2, polyether polyol A3, polyester polyol A4, a chain extension agent and a surfactant; the component B comprises the raw materials of polyester polyol B1, polyether polyol B2, polyether polyol B3, polyester polyol B4, isocyanate and a storage stabilizer; and the component C is an alcamines catalyst. When the finally prepared polyurethane shoe sole stock solution is used for polyurethane shoe sole production, the elasticity and hand feeling of a PU shoe sole are greatly improved, the rebounding rate isas high as 38%, the folding resistance is as high as 50 thousands without cracks, and therefore the stock solution has high application value and is suitable for production of outsoles of cotton-padded shoes and cloth shoes.

Owner:JIANGSU HUADA NEW MATERIAL CO LTD

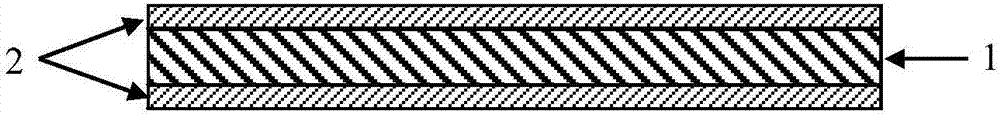

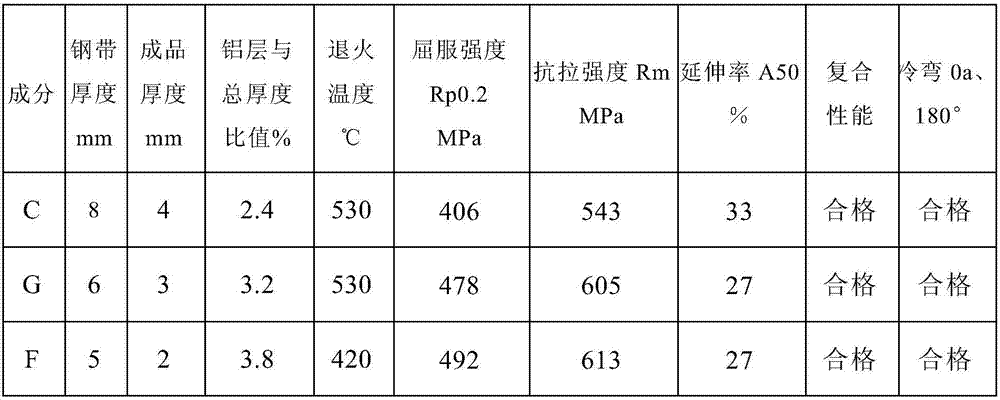

Lightweight aluminum coated sheet strip and production method thereof

ActiveCN107881412AHigh strengthGood cold bendingMetal rolling arrangementsChemical compositionStrip steel

The invention discloses a lightweight aluminum coated sheet strip and a production method thereof. The lightweight aluminum coated sheet strip is of an aluminum strip-steel strip composite structure.The steel strip comprises, by weight, 0.04-0.08% of C, greater than 0 and less than or equal to 0.005% of Si, 0.9-1.8% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, lessthan or equal to 0.005% of Al, 0.0062-0.02% of N, 0.006-0.05% of O, 0.002-0.004% of Ca, 0.01-0.03% of Ti, 0.01-0.03% of Nb and the balance Fe and inevitable impurities, wherein the sum of O and N isgreater than or equal to 0.013%, and 0.5<=(O+N) / (P+S)<=5. According to the aluminum coated sheet strip, the yield strength is 400 MPa or above, the tensile strength is 500-800 MPa, meanwhile, the elongation A50% is 18% or above, thus, the aluminum coated sheet strip has the strength of steel, the properties such as good plasticity, colding bending, stamping and the like and the characteristics ofcorrosion resistance, radiating performance and attractive appearance of aluminum, and can be used for production of radiators, radiating fins and wheels, and lightweight design can be achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

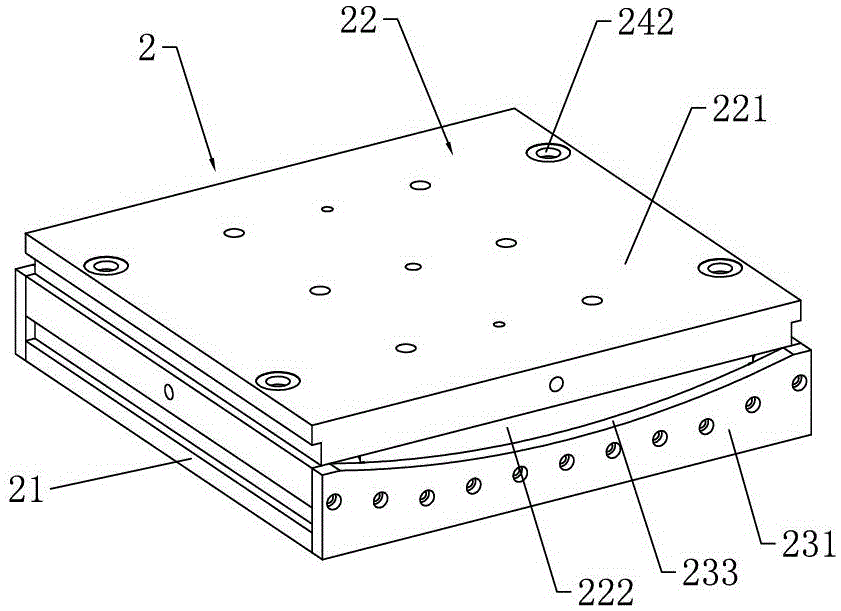

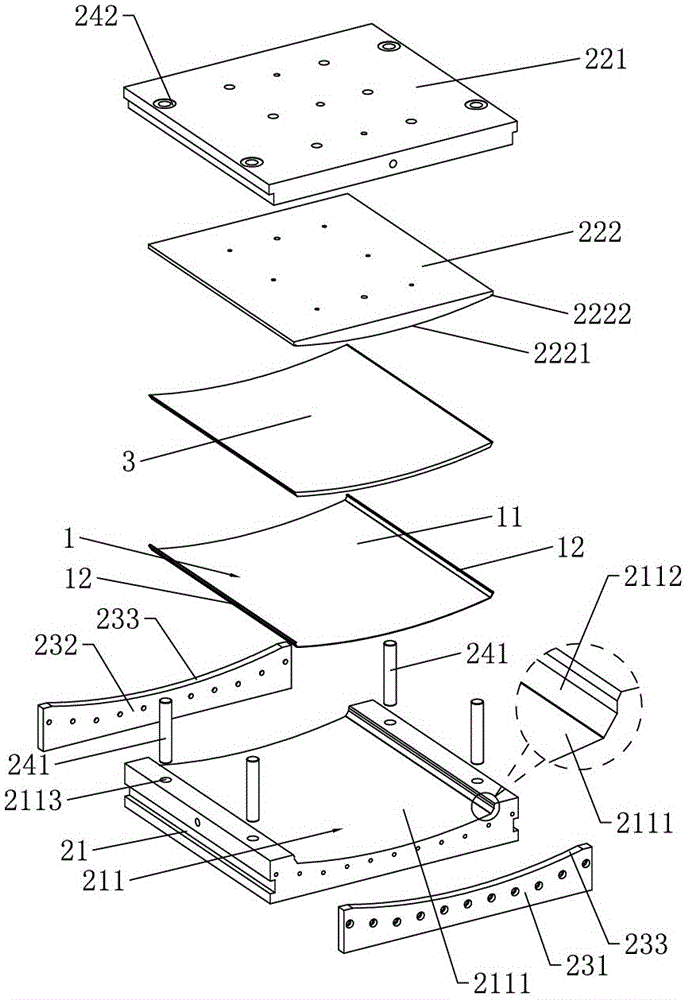

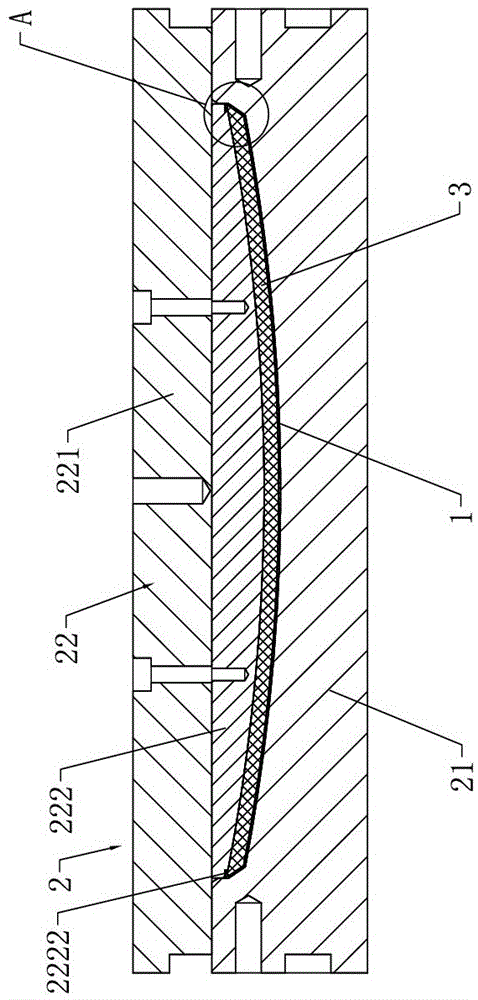

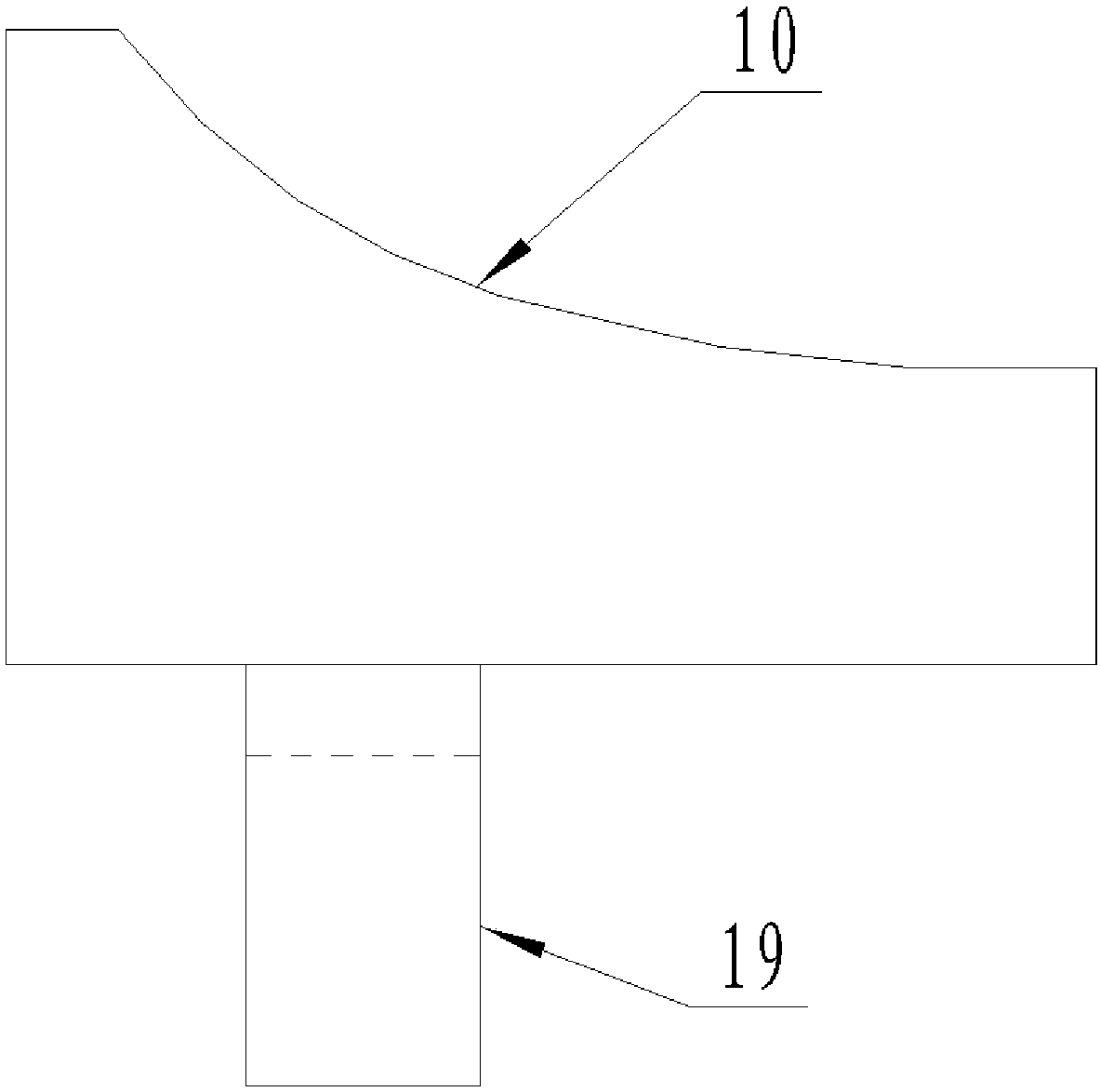

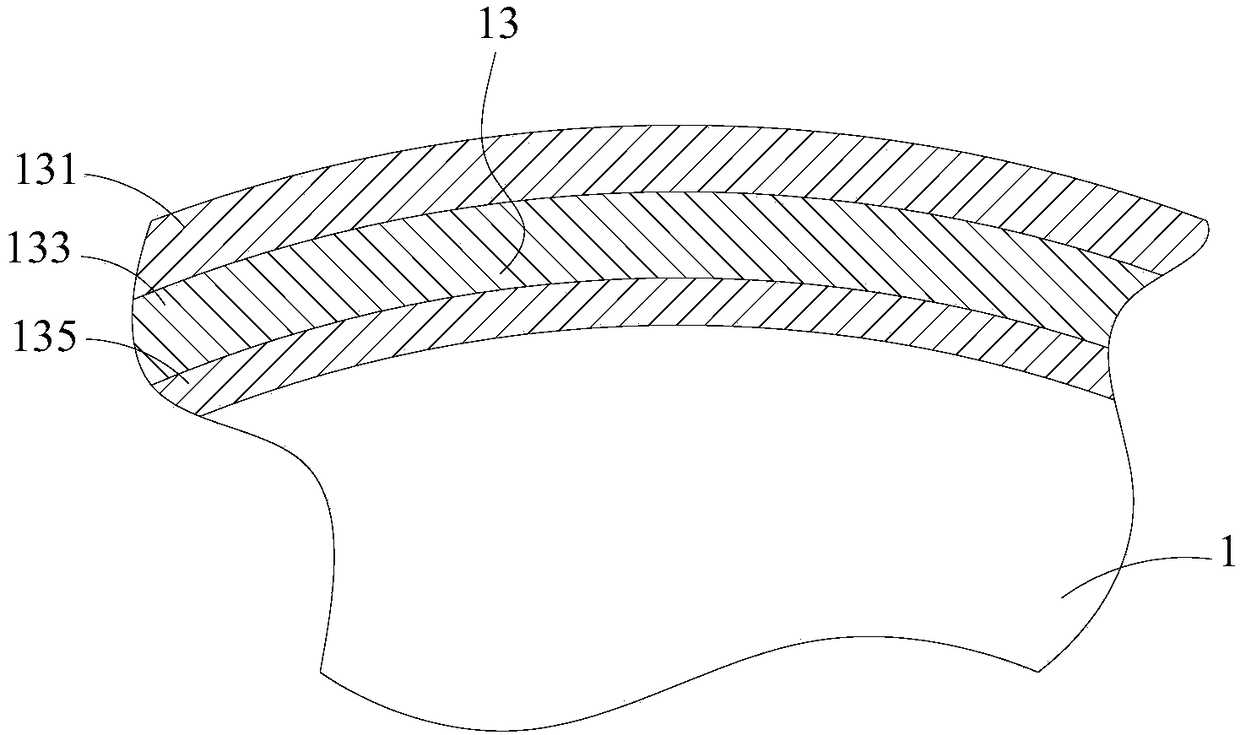

Process for manufacturing large-radius neutron absorbing laminate with end face angle of 45 degrees

InactiveCN106548815AEfficient productionProduction applicableProtective equipmentLaminationAlcoholBoron carbide

The invention discloses a process for manufacturing a large-radius neutron absorbing laminate with an end face angle of 45 degrees. The method includes the following steps: a, clipping an aluminum plate; b, polishing a filling contact surface of the aluminum plate; c, performing bending process on the aluminum plate; d, manufacturing an absorbing layer pressing die; e, arranging the absorbing layer pressing die on a 80T four-column hydraulic press; f, using ethyl alcohol to clean the absorbing layer pressing die; g, evenly pasting a Teflon protective film on an arc forming surface of a forming upper die; h, performing Vaseline coating; i, putting the aluminum plate in a lower die forming groove, coating the aluminum with glue; j, putting boron carbide filling in the lower die forming groove, and then performing pre-pressing through a stainless steel roller; k, closing the dies, and keeping a pressure; l, performing static curing; and m, removing the die, and completing manufacturing of the neutron absorbing laminate. Through the steps the process can effectively produce arc neutron absorbing laminates, can be effectively used for production and processing of large-radius neutron absorbing devices.

Owner:DONGGUAN UNIV OF TECH

Environment-friendly full-automatic bean curd production line and production method thereof

PendingCN109090265AGuaranteed timeGuaranteed temperatureCheese manufactureFood scienceTemperature controlProduction line

The invention relates to an environment-friendly full-automatic bean curd production line. The environment-friendly full-automatic bean curd production line comprises an automatic quantitative feedingand stirring system, an automatic temperature-controlled timing heating system, an automatic temperature-controlled cooling system and an automatic quantitative mixing and dispersing system which aresequentially connected. According to the environment-friendly full-automatic bean curd production line disclosed by the invention, through performing automatic quantitative feeding and stirring to make pulp, performing automatic temperature-controlled timing pulp stewing, performing automatic temperature reducing and cooling, and performing automatic quantitative discharging, dispersing, mixing and pulp solidification, time and space required by washing and soaking are reduced greatly, investment of equipment in aspects of washing, soaking, pulp milling and separating is also saved, and the pulp solidification standardization is guaranteed; besides, in the whole production course, no sewage, no bean residues and no yellow pulp water are discharged, so that the problem of environment pollution caused by soybean product enterprises is solved. The environment-friendly full-automatic bean curd production line has the characteristics of being short in production cycle and low in occupied space, can be operated in a one-button manner, and is free from discharging of sewage and bean residues; the quality of products is guaranteed to be consistent; the environment-friendly full-automaticbean curd production line is suitable for the production of large-scale soybean product enterprises.

Owner:LIANYUNGANG RIFENG CALCIUM & MAGNESIUM

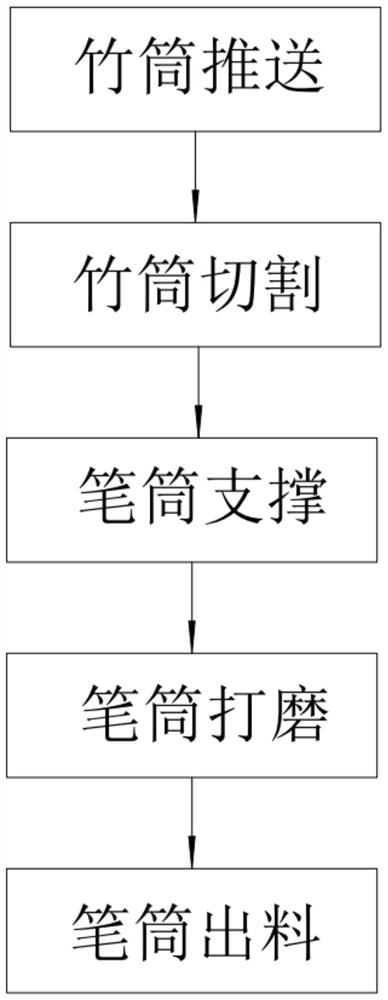

Bamboo pen container continuous production technology

InactiveCN111805673AIncrease productivityIncrease contact forceCane mechanical workingWood working apparatusRotating discContinuous production

The invention provides a bamboo pen container continuous production technology. The bamboo pen container continuous production technology comprises the following steps of bamboo tube pushing, bamboo tube cutting, pen container supporting, pen container polishing and pen container discharging. According to the bamboo pen container continuous production technology, a rotating disc is arranged on anauxiliary worktable, a plurality of installation assemblies are installed on the rotating disc in a rotating mode, positioning assemblies abutting against a bamboo tube and cutting assemblies abuttingagainst the outer wall of the bamboo tube are arranged on the installation assemblies, a driving assembly drives the installation assemblies to pass through a cutting station, a polishing station anda discharging station in sequence through the rotating disc, the driving assembly can drive the installation assemblies to carry out self-rotation to carry out cutting and polishing through a transmission assembly, then the process of bamboo tube cutting, pen container polishing and pen containing discharging can be achieved, and the production efficiency of pen containers is greatly improved.

Owner:临泉县金钉子生产力促进中心有限公司

Crosslinking modified jatropha curcas cake meal adhesive and preparation method thereof

InactiveCN103952117ASimple and fast operationEase of industrial productionNon-macromolecular adhesive additivesProtein adhesivesEpoxyPolymer science

The invention provides a crosslinking modified jatropha curcas cake meal adhesive and a preparation method thereof. The preparation process is as follows: adding 80 parts of jatropha curcas cake meal, 187-320 parts of water and 5.6-12 parts of alkali into a reaction kettle, stirring for 5 min, adding 1.6-3.2 parts of ethylene glycol and 5-20 drops of silicone oil, heating to 90 DEG C, insulating and stirring for 3 h, cooling and discharging materials. Before usage, 6-12 parts of a mixture containing epoxy resin and melamine resin in a weight ratio of 1:1-1:2 is added into the adhesive, and uniformly mixed. The jatropha curcas cake meal adhesive provided by the invention has the advantages of simple preparation process, moderate viscosity and strong operationality, and can effectively improve the comprehensive utilization rate of jatropha curcas cake meal. The adhesive has excellent strength and water resistance performance, and performance indexes meeting the requirements of type I and type II glued boards specified in the national standard GB / T9846.3-2004.

Owner:SOUTHWEST FORESTRY UNIVERSITY

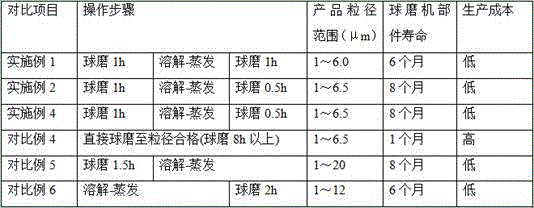

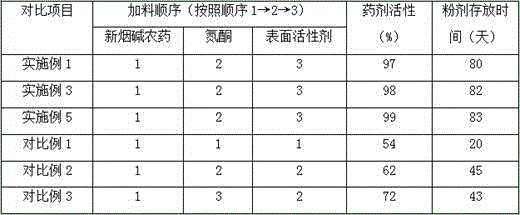

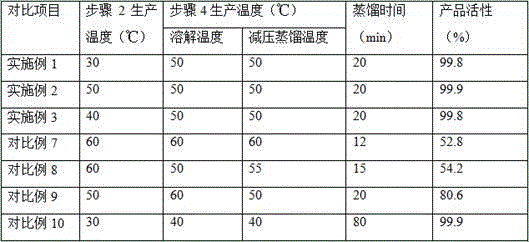

Mechanical preventing and controlling additive for anabasine pesticide and production method thereof

InactiveCN106818757AExtended shelf lifeImprove stabilityBiocideAnimal repellantsMass ratioAntioxidant

The invention discloses a mechanical preventing and controlling additive for anabasine pesticide and a production method thereof. The mechanical preventing and controlling additive is wettable powder with the grain size of 1.0-6.5mu m. The additive is composed of an anabasine pesticide and accessories at the mass ratio of (1-14):20, wherein the accessories comprise the following components in parts by weight: 2-10 parts of sodium dodecyl sulfate, 5-8 parts of a nonionic and anion compound surface active agent, 0.2-3 parts of an antioxidant, 1.3-4 parts of azone, 0.5-10 parts of a dispersing agent, 1-8 parts of sodium carboxymethyl starch and 30-57 parts of padding. According to the invention, the formula and production processes for the wettable powder of the anabasine pesticide are modified, so that the active time and storage time of the wettable powder are prolonged, the whole technology is more suitable for industrial production, and the production cost is optimized to the minimum.

Owner:江苏克胜集团股份有限公司 +1

Method of continuously purifying quartz powder for production of cosmetics

The invention discloses a method of continuously purifying quartz powder for production of cosmetics, which includes the following steps: S1) selecting high-quality quartz stone ore; S2) crushing thequartz stone ore into smaller stone materials through a stone crusher, and grinding the smaller stone materials into sand granules through a stone grinder, wherein water is continuously added during the grinding process, so that water, bringing the sand granules, flows into a settling tank so as to remove a yellow-brown skin on surface of the raw ore; S3) delivering the sand granules in the settling tank to a roasting chamber to roast the sand granules into dry sand granules, and sieving the dry sand granules via a vibrating sieve, wherein iron removal is carried out via a magnet bar and a magnet grate during the sieving process; S4) moving sieved fine dry sand granules to a reaction kettle, uniformly adding a less amount of benzoyl peroxide crystal, and uniformly stirring and mixing the components for 15-30 min at 80-120 rpm, during stirring, proper amounts of water and perlite powder are added. The method has reasonable design, is simple and low-cost, and is low in irritation on skinon the basis of ensuring a bright white color of the quartz powder, and is suitable for production of cosmetics.

Owner:滁州方大矿业发展有限公司

Manufacturing method of high-silicon quartz powder used for producing cosmetics

InactiveCN108478450AProduction applicableGuaranteed white colorCosmetic preparationsToilet preparationsDry sandColloid

The invention discloses a manufacturing method of a high-silicon quartz powder used for producing cosmetics. The manufacturing method comprises the following steps: S1, choosing high-quality quartz stone mineral material; S2, processing into smaller stones through a stone breaking machine, rolling the small stones into sand grains by a stone roll, constantly adding water in the rolling process, enabling the sand grains to flow into a settling pond along with water, removing yellowish-brown surface on the surface of the raw ore; S3: transporting the sand grains in the settling pond to a bakingroom, baking into dry sand grains, screening by a vibrating screen, removing iron by using a magnet bar and a repelling magnet; S4: putting the screened dry sand grains into a high temperature sintering furnace of 700-900 DEG C, and sintering for 2-4 hours at the high temperature to obtain a sintered material; and S5, sequentially adding the sintered material, simethicone and ferric oxide into a colloid mill, and accurately milling sufficiently for 20-40 minutes. The preparation method is simple, the cost is low, the irritation to the skin is small on the premise that the bright white color ofthe high-silicon quartz powder is guaranteed, and the manufacturing method is suitable for the production of cosmetics.

Owner:滁州方大矿业发展有限公司

Multi-component and multi-color roving spinning device

The invention discloses a multi-component and multi-color roved yarn spinning device. The multi-component and multi-color roved yarn spinning device comprises a roving machine (40), a first bundling device (10) and / or a second bundling device (20), wherein the first bundling device (10) and / or the second bundling device (20) are / is arranged outside the roving machine (40); the first bundling device (10) contains two channels for finisher drawing strips or roving strips to penetrate; the second bundling device (20) contains three channels for the finisher drawing strips or the roving strips to penetrate. The multi-component and multi-color roved yarn spinning device disclosed by the invention can be used for feeding the finisher drawing strips and one or more roving strips at the same time, so that the aim of producing multi-color and multi-component roved yarns with different styles is realized. The multi-component and multi-color roved yarn spinning device has the advantages of simplicity and efficiency, easiness of manufacturing and mounting the device and the like, and is suitable for large-batch and multi-variety production.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

Automatic rope belt production equipment

ActiveCN113386085ACut off applicableQuick cutMetal-working hand toolsConveyor partsStructural engineeringWorkbench

The invention relates to the technical field of rope belt production, in particular to automatic rope belt production equipment which comprises a workbench, a rope belt main body feeding device, a rope buckle feeding device, a rope buckle assembling device and a rope belt discharging device. The rope belt main body feeding device comprises a rope belt main body feeding module, a rope belt main body traction module, a rope belt main body cutting module and a rope belt main body taking and placing module; and the rope belt main body cutting module comprises a cutter, and the cutter is a hot melting cutter. According to the automatic rope belt production equipment, a manual mode can be replaced to produce rope belts, a large amount of workload of operators can be reduced, the production efficiency of the rope belts can be improved, and the automatic rope belt production equipment can be well suitable for mass production of the rope belts.

Owner:东莞市加壹智能科技有限公司

Production device and method of biological feeds

ActiveCN103126042BRealize continuous mass productionPrevent rustFeeding-stuffWork performanceAutomation

Owner:张有聪

Easy-welding low-carbon bainitic steel and manufacturing method thereof

InactiveCN101787489BSimple production processProduction applicableTemperature control deviceMetal rolling arrangementsChemical compositionBoron

The invention discloses an easy-welding low-carbon bainitic steel and a manufacturing method thereof, belonging to the technical field of microalloy steel. The steel comprises the chemical components by weight percent: 0.02-0.08% of C, 1.20-1.80% of Mn, 0.10-0.50% of Si, less than or equal to 0.010% of S, less than or equal to 0.015% of P, 0.10-0.30% of Mo, 0.020-0.050% of Nb, 0.03-0.10% of V, 0.005-0.030% of Ti, 0.0050-0.010% of N, 0.0005-0.0020% of B, less than or equal to 0.035% of Al and balance of Fe and inevitable impurities. The proportion between the boron content and the nitrogen content in the steel simultaneously meets the conditions that 3N-10B is more than or equal to 0.005 and less than or equal to 0.015, and Ti+V+10B is more than or equal to 8.525N. The production process of smelting by an electric furnace or a converter, external refining, continuous casting and controlled rolling and cooling is adopted. The invention has the advantages that the yield strength of the steel is more than or equal to 550MPa, the tensile strength is more than or equal to 670MPa, the elongation is more than or equal to 20%, and the charpy impact energy under -40 DEG C is more than or equal to 200J; the charpy impact energy under -40 DEG C in a near weld zone is more than or equal to 100J when the weld heat input is 20-100Kj / cm; and the production process is simple and convenient.

Owner:YANSHAN UNIV

Rice crust pressing and forming device

InactiveCN108077981AFlexible operationGood anti-adhesionFood shapingRice dishesMechanical engineering

The utility model discloses a rice crust pressing and forming device, which is arranged at a rice conveying belt. The rice crust pressing and forming device comprises a rice pressing roller set. The rice pressing roller set is provided with two rollers. The two rollers are respectively located above the rice conveying belt or below the rice conveying belt. The two rollers are in right up-down positional relationship. The two rollers are respectively marked as an upper roller and a lower roller according to the positional relationship. The axial direction of the upper roller and the lower roller is perpendicular to the conveying direction of the rice conveying belt, the cylindrical surface of the lower roller is in contact with the lower surface of the rice conveying belt, and a uniform anti-stick sleeve is closely attached to the cylindrical surface of the upper roller. The uniform anti-stick sleeve includes a skeleton layer and an anti-stick layer, and the anti-stick layer covers theskeleton layer. The rice crust pressing and forming device has the advantages of being able to complete the rice pressing and forming function in the upper and middle stream processes of large-scale,high-efficiency and high-quality rice crust production, and at the same time the device can avoid the sticking phenomenon of rice.

Owner:毕丽萍

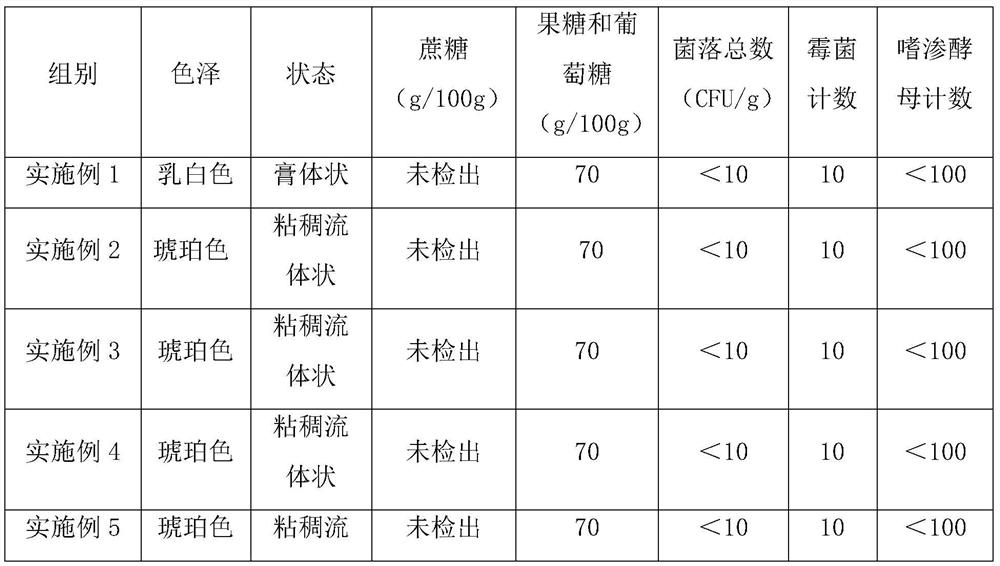

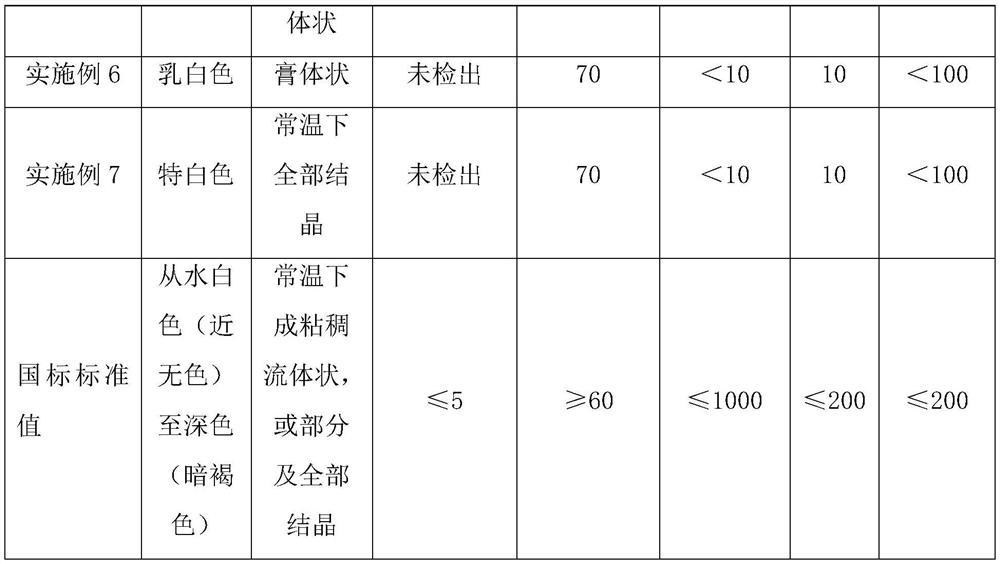

Linden snow honey and preparation method and application thereof

PendingCN111657463AHigh nutritional valueSolve the problems that cannot realize industrialized productionFood ingredient as colourFood thermal treatmentBiotechnologyNutritive values

The invention relates to the field of food processing, and particularly discloses linden snow honey and a preparation method and application thereof. The linden snow honey comprises linden honey and an air crystal nucleus, wherein the preparation method of the air crystal nucleus comprises the steps that the linden honey is filtered to remove impurities and then placed in the environment of 10-15DEG C to be crystallized, and the air crystal nucleus is obtained. The prepared linden snow honey is snow white in color and high in nutritive value, the air crystal nucleus is added into the linden honey to prepare the linden snow honey, repeated brewing and natural ripening are not needed, and the problems that most existing linden snow honey needs to be repeatedly brewed and naturally ripened,and industrial production cannot be achieved are solved. The preparation method is simple, emulsification is achieved through vacuum concentration and adding of the air crystal nucleus, the prepared linden snow honey can be completely crystallized, is in a solid cream shape, is snow white in color, is suitable for industrial production and has wide market prospects.

Owner:陕西安康幸福农业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com