Automatic rope belt production equipment

An automatic production and rope technology, which is applied in the direction of winding strips, sending objects, hand-held tools, etc., can solve the problems of low efficiency, heavy workload of operators, and inability to apply rope production well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

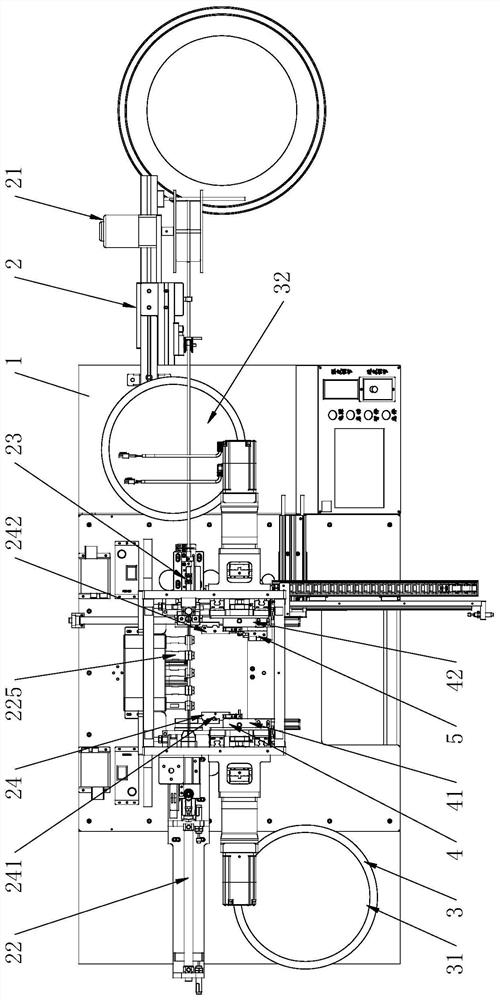

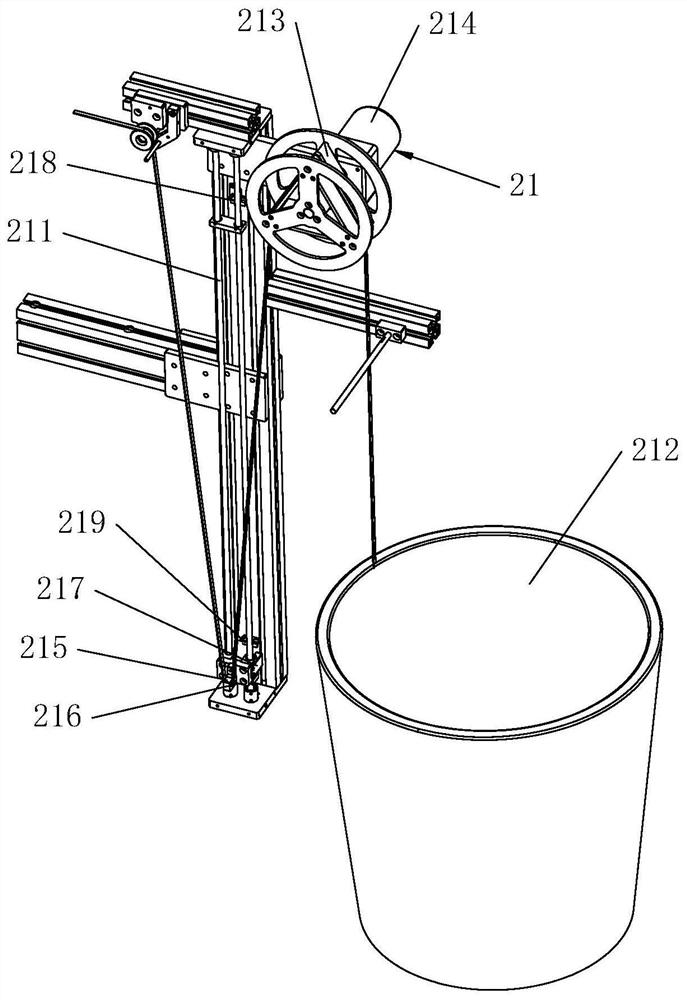

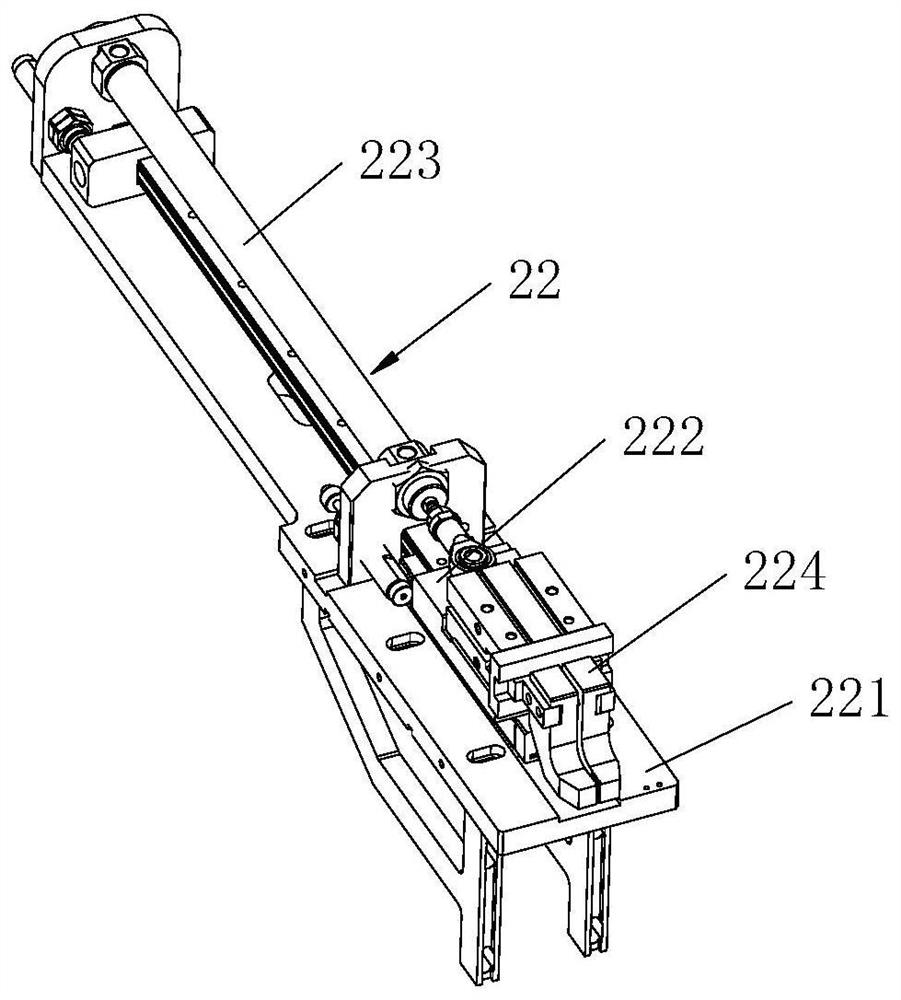

[0038] Below in conjunction with accompanying drawing, the present invention will be further described, as Figure 1-9 As shown, the present invention includes a workbench 1, a rope main body feeding device 2, a rope buckle feeding device 3, a rope buckle assembly device 4, and a rope belt unloading device 5, and the rope main body feeding device 2 includes a rope Main body feeding module 21, rope main body traction module 22, rope main body cutting module 23, rope main body pick-and-place module 24; said rope main body cutting module 23 includes a cutter 234, and said cutter 234 For hot melt cutter;

[0039] The rope main body traction module 22 is used to clamp and pull one end of the rope material sent out by the rope main body feeding module 21; the rope main body cutting module 23 is used to pull the rope main body traction module 22 pull the rope material of a certain length to cut off and form the rope main body of the required length for assembly; Middle; the cord bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com