Hot rolling process for quality carbon structural steel

A carbon structural steel and carbon structure technology, applied in the field of hot-rolled steel, can solve the problems of cracks, affecting product performance, high hardness, shortening the incubation period, reducing the risk of equipment damage, and increasing the phase transition temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

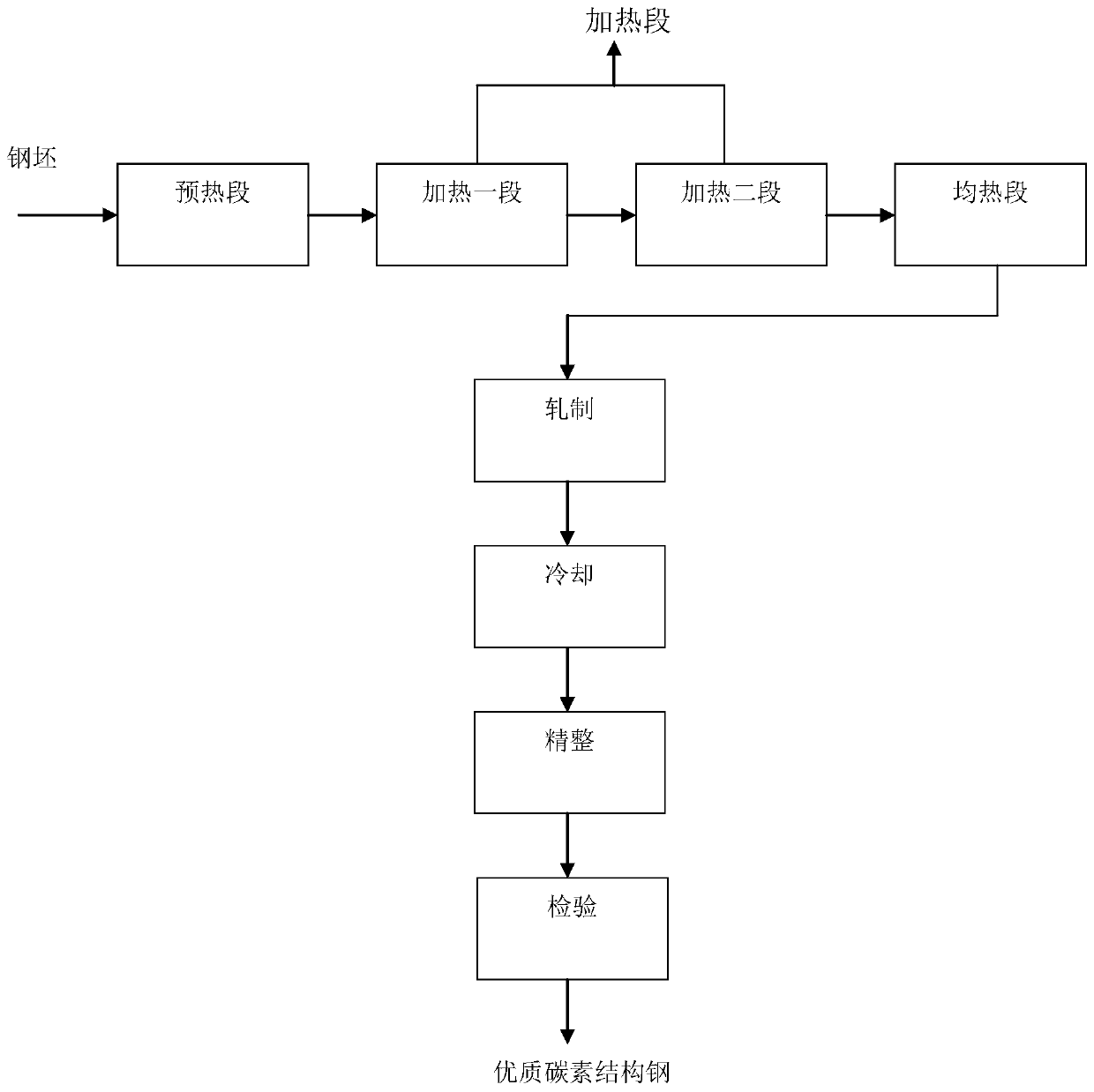

[0027] The invention provides a hot-rolling process for high-quality carbon structural steel, which includes preheating, heating, soaking, rolling, cooling and finishing for a billet. The heating is divided into a heating stage and a heating stage. Finishing involves crimping the billet and includes the following steps:

[0028] (1) The chemical composition of the billet used in the preheating section is calculated by weight percentage: C: 0.45%, Si: 0.20%, Mn: 0.12%, P: 0.015%, S: 0.02%, Al: 0.0025%, Ti: 0.01%, Cr: 0.01%, Nb: 0.016%, and the rest are Fe and unavoidable impurities.

[0029] (2) The temperature of the preheating section is 750°C; the temperature of the heating section 1 is 920°C; the temperature of the heating section 2 is 1200°C; the heating time of the heating process is 135min;

[0030] (3) The steel billet enters the rolling process from the heating process, the rolling start temperature of the rolling process is 960°C, and the final rolling temperature is...

Embodiment 2

[0034] The invention provides a hot-rolling process for high-quality carbon structural steel, which includes preheating, heating, soaking, rolling, cooling and finishing for a billet. The heating is divided into a heating stage and a heating stage. Finishing involves crimping the billet and includes the following steps:

[0035] (1) The chemical composition of the billet used in the heating section is calculated by weight percentage: C: 0.45%, Si: 0.20%, Mn: 0.12%, P: 0.015%, S: 0.02%, Al: 0.0025%, Ti: 0.01 %, Cr: 0.01%, Nb: 0.016%, and the rest are Fe and unavoidable impurities.

[0036] (2) The temperature of the preheating section is 800°C; the temperature of the heating section 1 is 1040°C; the temperature of the heating section 2 is 1160°C; the heating time of the heating process is 180min;

[0037] (3) The steel billet enters the rolling process from the heating process, the rolling start temperature of the rolling process is 960°C, and the final rolling temperature is ...

Embodiment 3

[0041] The invention provides a hot-rolling process for high-quality carbon structural steel, which includes preheating, heating, soaking, rolling, cooling and finishing for a billet. The heating is divided into a heating stage and a heating stage. Finishing involves crimping the billet and includes the following steps:

[0042](1) The chemical composition of the billet used in the heating section is calculated by weight percentage: C: 0.45%, Si: 0.20%, Mn: 0.12%, P: 0.015%, S: 0.02%, Al: 0.0025%, Ti: 0.01 %, Cr: 0.01%, Nb: 0.016%, and the rest are Fe and unavoidable impurities.

[0043] (2) The temperature of the preheating section is 800°C; the temperature of the heating section 1 is 1040°C; the temperature of the heating section 2 is 1160°C; the heating time of the heating process is 180min;

[0044] (3) The steel billet enters the rolling process from the heating process, the rolling start temperature of the rolling process is 960°C, and the final rolling temperature is 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com