Environment-friendly full-automatic bean curd production line and production method thereof

A production method and fully automatic technology, applied in cheese substitutes, dairy products, applications, etc., can solve problems such as poor solidification state, a large amount of sewage, bean dregs, and soft texture of tofu, so as to maintain consistent product quality and shorten the production cycle , taste smooth and delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

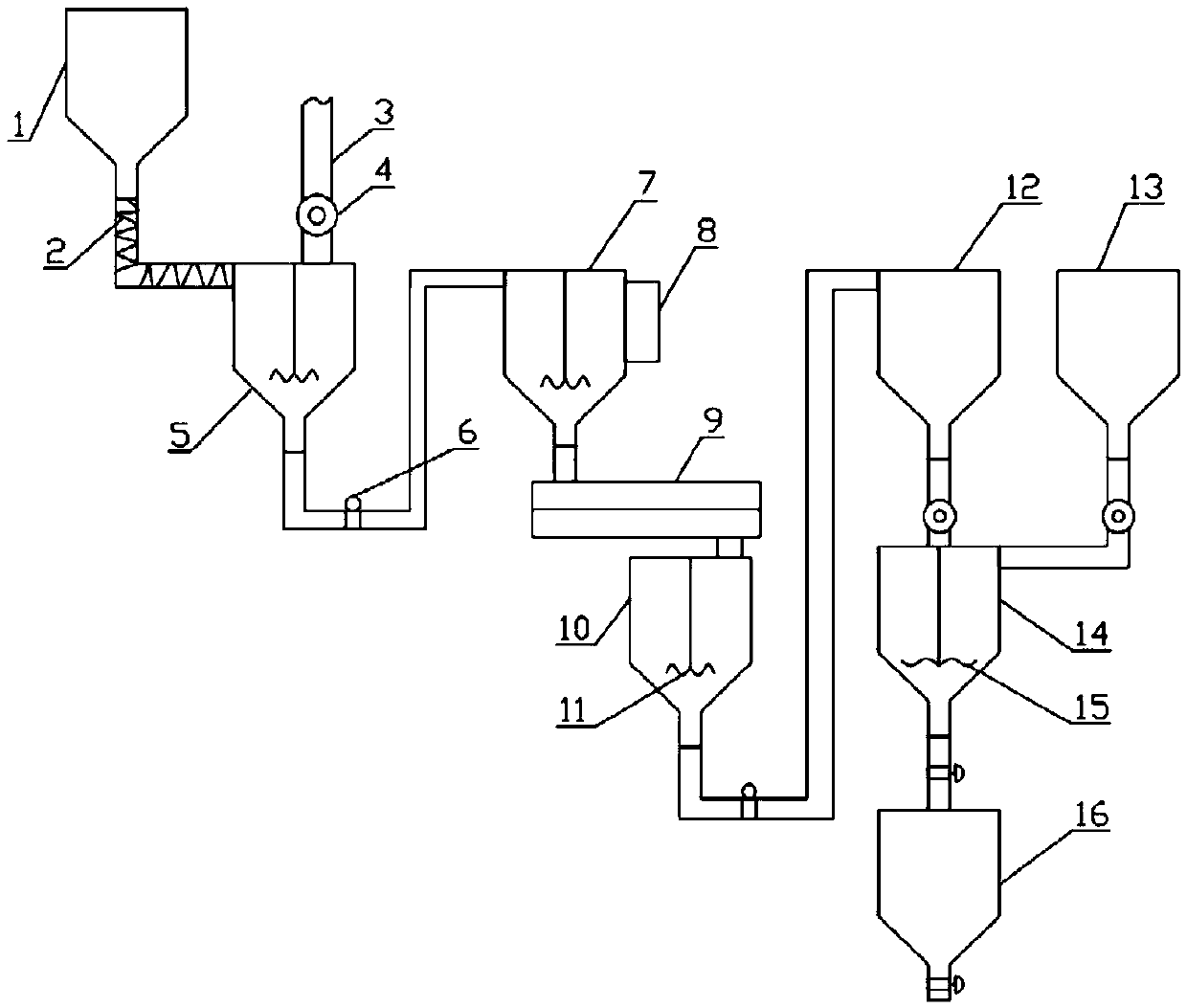

[0027] Embodiment 1, with reference to figure 1 , an environment-friendly full-automatic tofu production line, which includes an automatic quantitative feeding and mixing system, an automatic temperature-controlled timing heating system, an automatic temperature-controlled cooling system, and an automatic quantitative mixing and dispersing system connected in sequence; Made into raw soybean milk, no sewage and bean dregs are discharged;

[0028] The automatic quantitative feeding and mixing system includes a powder raw material tank 1 and a high-speed mixing tank 5, the powder raw material tank 1 communicates with the high-speed mixing tank 5 through a discharge mechanism 2, the high-speed mixing tank 5 is externally connected with a clean water supply pipeline 3, and the clean water supply pipeline 3 is provided with a metering pump 4 for injecting clean water into the high-speed mixing roller in proportion, and the high-speed mixing tank 5 is provided with a stirring blade f...

Embodiment 2

[0052] Embodiment 2, 1. Put 1 kg of whole component bean powder into the powder raw material tank, start the machine, set the weight of bean powder for production feeding, the ratio of bean powder and water to be 1:8, stirring speed 5000r / min, The stirring time is 5 minutes, the cooking temperature is 97°C, the holding time is 5 minutes, the cooling temperature of soybean milk is 30°C, the ratio of soybean milk to coagulant is 1000:5, the dispersion time of stew is 30s, and the dispersion speed is 6000r / min, start operation;

[0053] 2. Quantitatively put the raw soybean powder into the high-speed mixing tank through the screw, and at the same time automatically add water according to the set ratio for stirring and mixing to form raw soybean milk; after 5 minutes, the stirring is completed, and the raw soybean milk is transported to the heating mixing tank through the centrifugal pump;

[0054] 3. The steam valve is automatically turned on for heating. When the temperature of t...

Embodiment 3

[0059] Embodiment 3, 1. Put 1 kg of whole component bean powder into the powder raw material tank, start the machine, set the weight of bean powder for production feeding, the ratio of bean powder and water to be 1:5, stirring speed 5000r / min, The stirring time is 5 minutes, the cooking temperature is 97°C, the holding time is 5 minutes, the cooling temperature of soybean milk is 60°C, the ratio of soybean milk to coagulant is 1000:7.2, the dispersion time of stew is 20s, and the dispersion speed is 6000r / min, start operation;

[0060] 2. Quantitatively put the raw soybean powder into the high-speed mixing tank through the screw, and at the same time automatically add water according to the set ratio for stirring and mixing to form raw soybean milk. After 5 minutes, the stirring is completed, and the raw soybean milk is transported to the heating mixing tank through the centrifugal pump;

[0061] 3. The steam valve automatically opens for heating. When the temperature of the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com