Multi-component and multi-color roving spinning device

A multi-color, multi-component technology, applied in the direction of yarn, spinning machine, textile and papermaking, etc., can solve the problem of inability to produce multi-color, multi-component and different styles of segment roving, and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

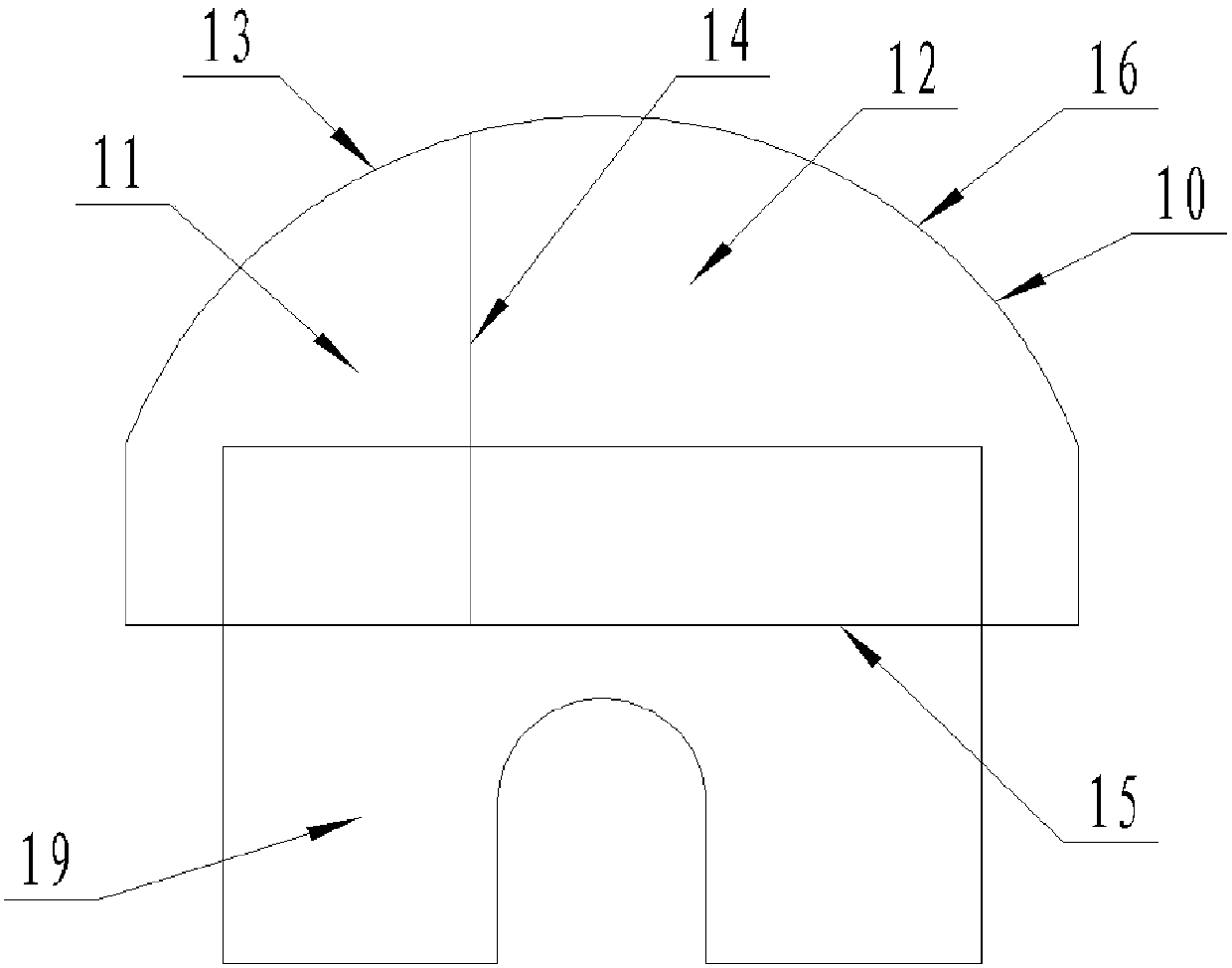

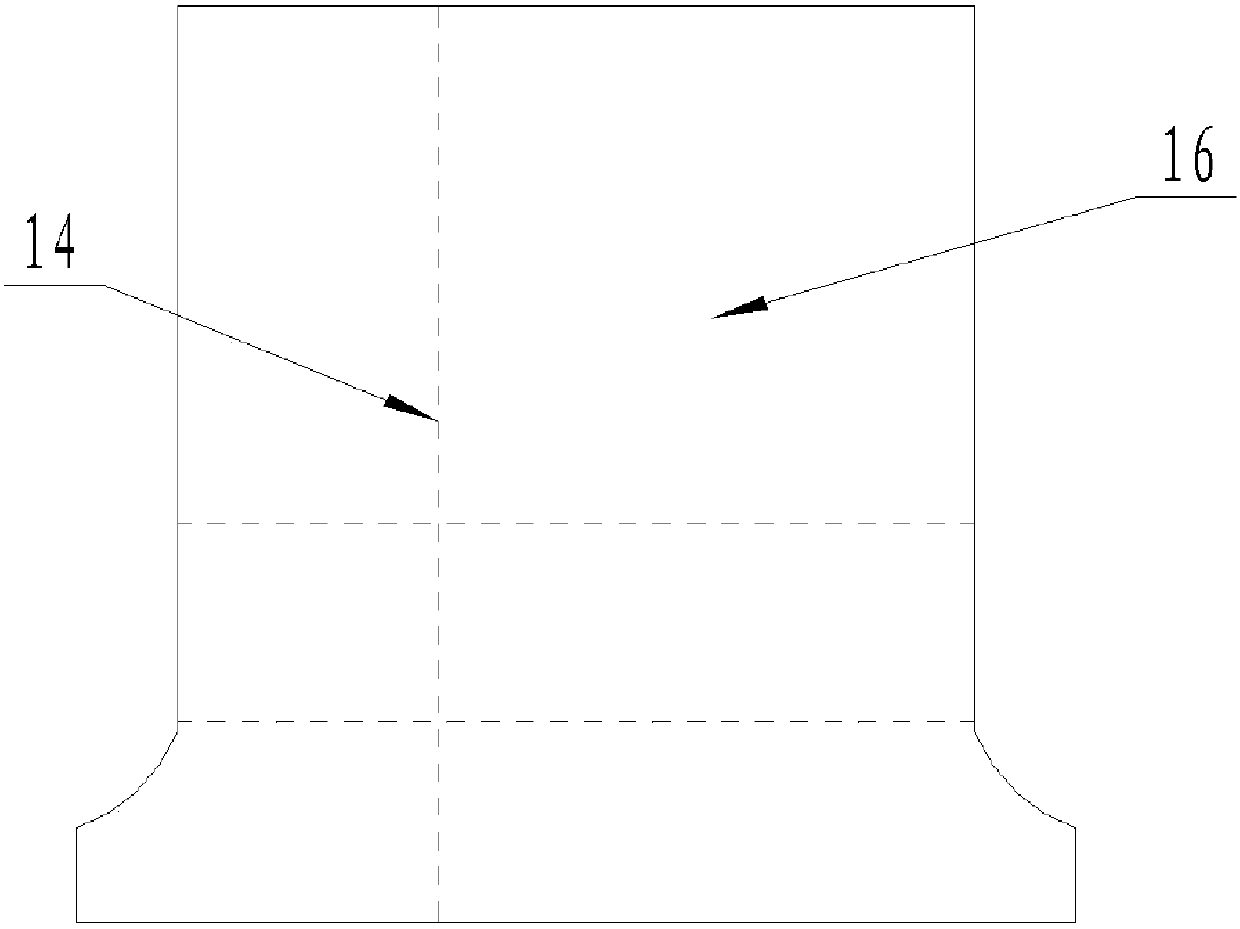

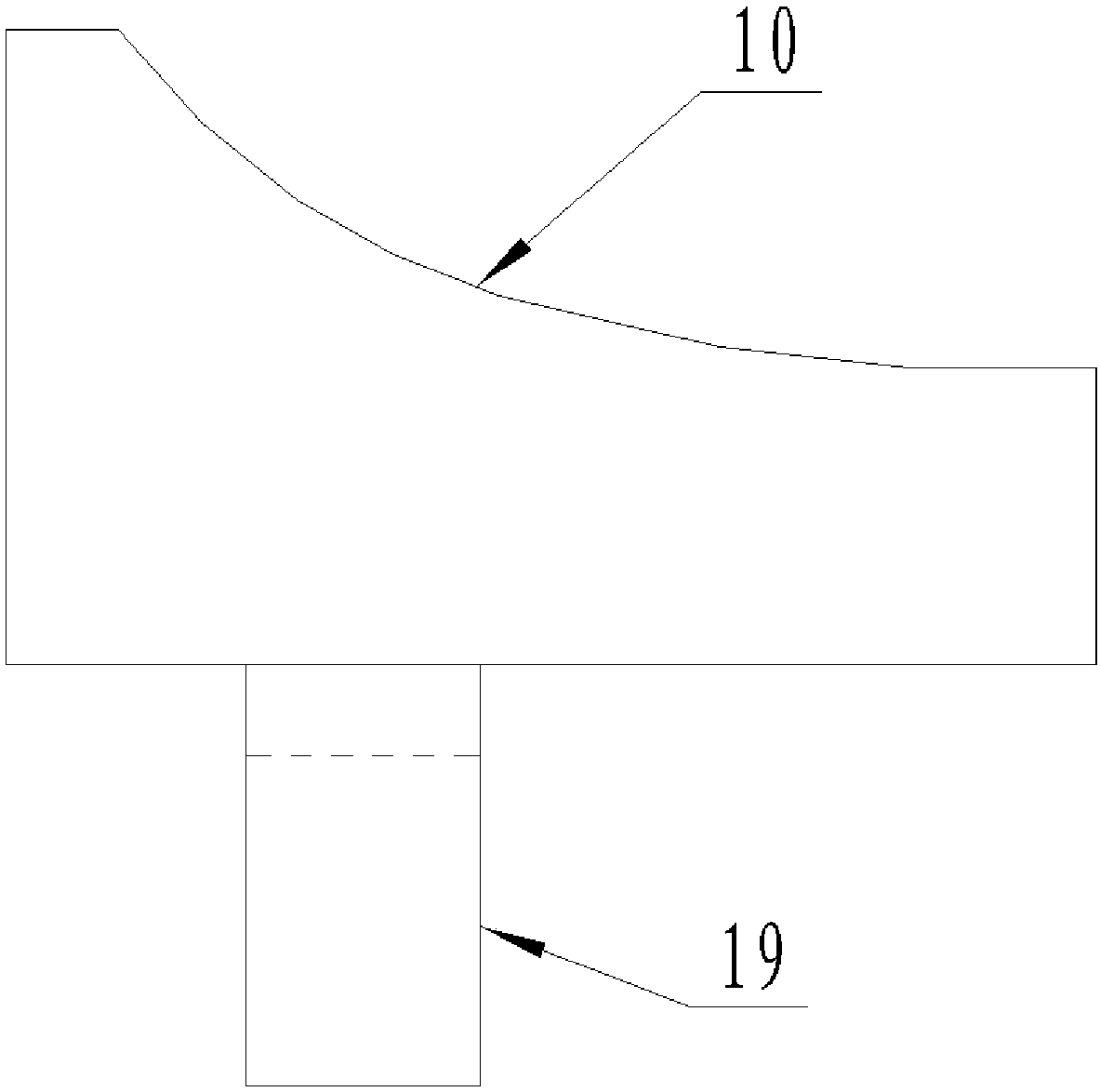

[0042] A multi-component and multi-color roving spinning device, comprising a roving frame 40 and two first converging devices 10, the two first converging devices 10 are arranged outside the roving frame 40, and the first converging device 10 contains an inlet port and the outlet end, the outlet end of a first clusterer 10 is towards the feeding port of the roving frame 40, and the outlet end of the other first clusterer 10 is towards the inlet end of the first clusterer 10, and in the first clusterer 10 The first channel 11 of the first cluster and the second channel 12 of the first cluster are provided through the first cluster 10, and the first channel 11 of the first cluster and the second channel 12 of the first cluster are horn-shaped structures , the large mouth end of the first channel 11 of the first cluster and the large mouth end of the second channel 12 of the first cluster correspond to the inlet port of the first cluster 10, the small port of the first channel 11...

Embodiment 2

[0050] Embodiment 1 introduces that the first type of bundler contains two channels, so it can be called a double-channel bundler. The drawing frame and a kind of roving slivers are combined to form a combined sliver. The following introduces the second type of clustering device and the combination of the second type of clustering device and the first type of clustering device. The second type of clustering device is the first type of An improvement of the cluster, the second cluster contains three channels, so it can be called a three-channel cluster, the specific structure of the three-channel cluster includes the second cluster and the first cluster The multi-component multi-color roving spinning device is as follows:

[0051] A multi-component and multi-color roving spinning device, comprising a roving frame 40, a first converging device 10 and a second converging device 20, the first converging device 10 and the second converging device 20 are arranged on the roving frame...

Embodiment 3

[0057] Embodiments 1 and 2 introduce the first type of cluster and the combination of the first type of cluster and the second type of cluster. The following introduces a multi-component and multi-color roving spinning device that only contains the second type of cluster. ,details as follows:

[0058] A multi-component and multi-color roving spinning device, comprising a roving frame 40 and two second converging devices 20, the two second converging devices 20 are arranged outside the roving frame 40, and the two second converging devices 20 contain Inlet end and outlet end, the outlet end of a second clusterer 20 is towards the feeding port of this roving frame 40, the outlet end of another second clusterer 20 is towards the inlet end of this one second clusterer 20, and the second clusterer 20 is provided with the first channel 21 of the second clusterer 20, the second channel 22 of the second clusterer and the third channel 27 of the second clusterer through the second clus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com