Linden snow honey and preparation method and application thereof

The technology of linden tree honey and linden tree is applied in the directions of food science, food ingredients as color, food heat treatment, etc. It can solve the problems that industrialized production cannot be realized, and achieve the effects of simple preparation method, broad market prospect, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

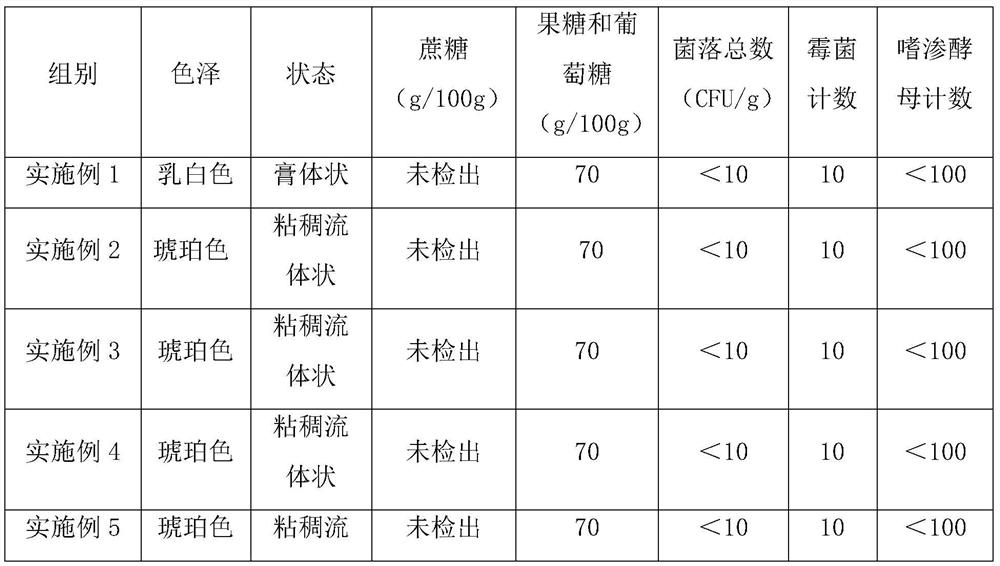

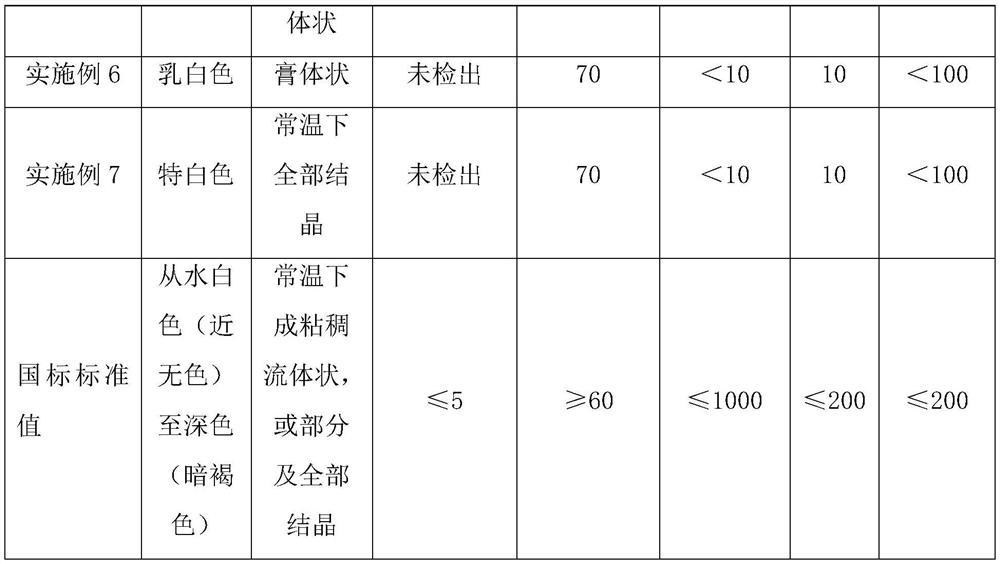

Examples

Embodiment 1

[0031] A preparation method of linden snow honey, comprising the following steps:

[0032] 1) Add the qualified linden honey raw material into the heating mixer, heat it to 48°C in the heating agitator with low-temperature heating, and keep it for about 45 minutes to melt all the linden honey raw materials and maintain good fluidity ;

[0033] 2) The linden tree honey after melting in step 1) is carried out preliminary screening, specifically use 80 mesh screens to filter and screen the linden tree honey after melting, keep the linden tree honey temperature at 42 ℃ in the preliminary screening process, with Ensure good fluidity and uniform flow rate of linden honey;

[0034] 3) add the linden tree honey after preliminary screening to vacuum concentration equipment and carry out vacuum concentration (the condition of described vacuum concentration is: control vacuum degree is-0.09MPa, temperature is 40 ℃) to moisture content is 16wt%%; During vacuum concentration, take a samp...

Embodiment 2

[0039]Compared with Example 1, except that "the linden tree honey after the heat preservation is used high-speed stirring equipment to stir 30 minutes under the stirring speed of 400 rev / mins, obtain stirring material, then according to the described stirring material of every 0.8kg (linden The proportion of adding 0.1kg air crystallization nuclei in the tree honey) is weighed and the air crystallization nuclei are injected into the mixing material, and placed in an environment of 10°C to continue stirring (400 rpm)" is replaced by "the linden tree honey after heat preservation Use high-speed stirring equipment to stir at a stirring speed of 900 rpm for 30 minutes to obtain a stirring material, then take by weighing the air crystallization according to the ratio of adding 0.1kg air crystal nucleus in the described stirring material (linden tree honey) of every 0.8kg The core is injected into the stirring material, and placed in an environment of 10° C. to continue stirring (900...

Embodiment 3

[0041] Compared with Example 1, except that "the linden tree honey after the heat preservation is used high-speed stirring equipment to stir 30 minutes under the stirring speed of 400 rev / mins, obtain stirring material, then according to the described stirring material of every 0.8kg (linden The proportion of adding 0.1kg air crystallization nuclei in the tree honey) is weighed and the air crystallization nuclei are injected into the mixing material, and placed in an environment of 10°C to continue stirring (400 rpm)" is replaced by "the linden tree honey after heat preservation Use high-speed stirring equipment to stir at a stirring speed of 600 rev / min for 30 minutes to obtain a stirring material, then take by weighing the air crystallization according to the ratio of adding 0.1kg air crystal nucleus in the described stirring material (linden tree honey) of every 0.8kg The core is injected into the stirring material, and placed in an environment of 10° C. to continue stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com