Rice crust pressing and forming device

A technology of forming device and rice cooker, which is applied in the fields of food forming, food science and application, can solve the problems of complex structure of equipment and equipment, low fault tolerance rate of functional parts, affecting the normal operation of equipment, etc. The effect of peeling off and prolonging the service life of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below according to the drawings and embodiments.

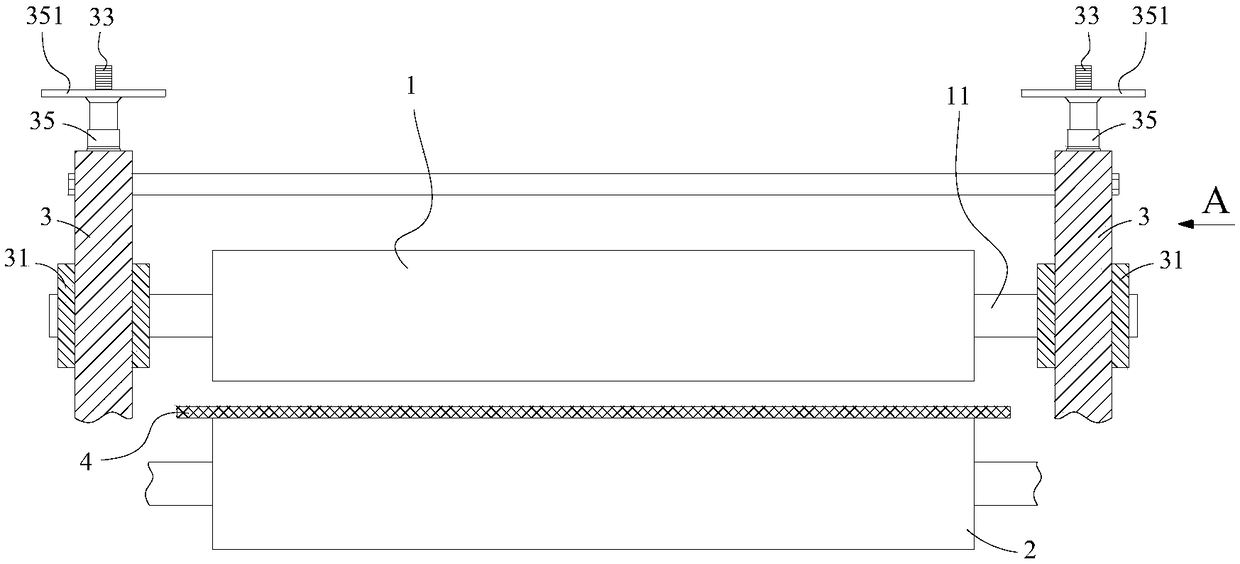

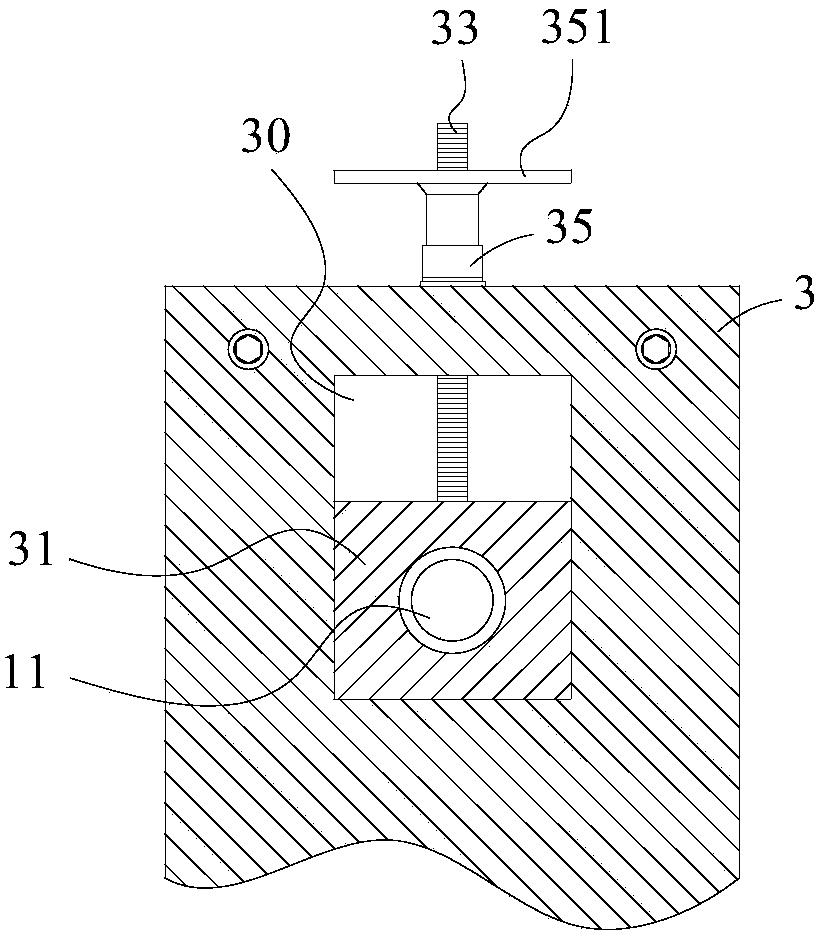

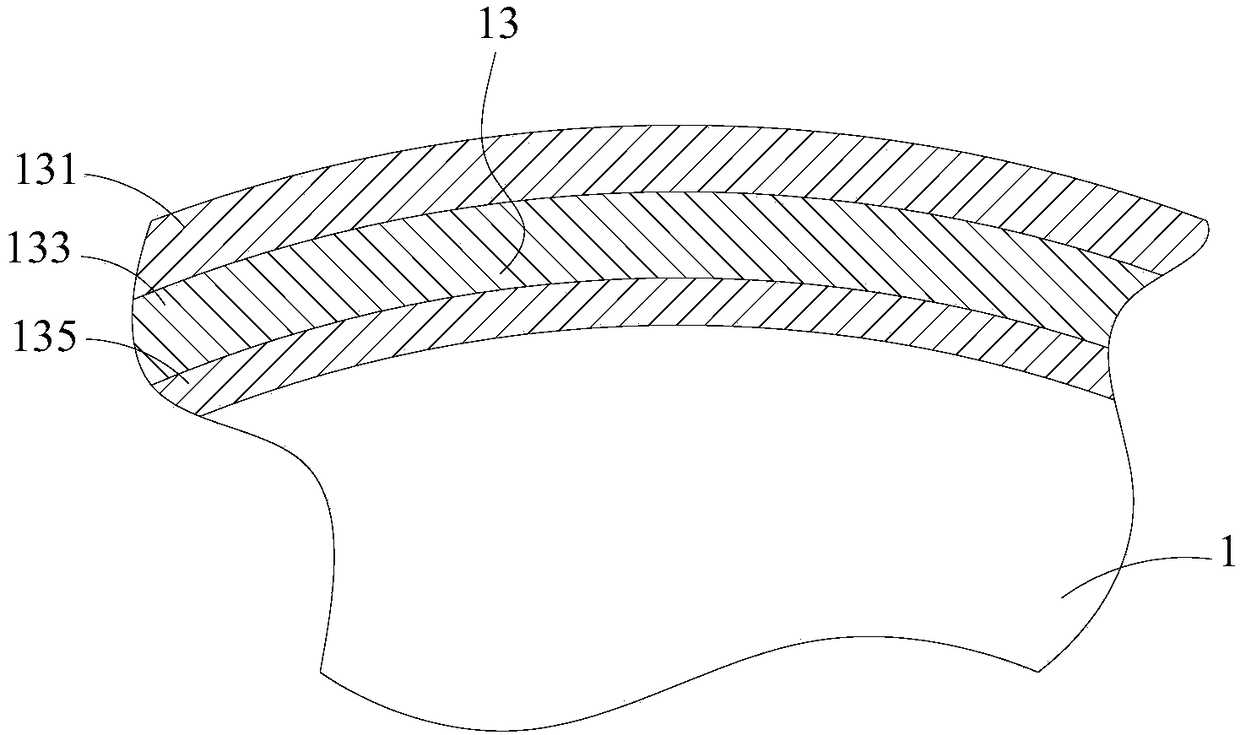

[0028] figure 1 It is the structural representation of rice crust pressing rice forming device of the present invention, figure 2 for figure 1 Schematic diagram of the angle of view in the A direction, image 3 It is a structural representation of the anti-sticking cover of the present invention, referring to figure 1 , figure 2 , image 3 , the present invention, the crisper rice pressing forming device is arranged at 4 places on the rice material conveyor belt. The upper and lower sides of the food conveyor belt 4, and the two cylinders 1, 2 are in the positional relationship between the upper and lower sides, and the two cylinders 1, 2 are recorded as the upper cylinder 1 and the lower cylinder 2 by the positional relationship, and the axial direction of the upper and lower cylinders 2 and the rice material The conveying direction of conveyer belt 4 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com