Method for controlling quality of castings obtained through low pressure casting and dynamic pressure detecting device thereof

A technology of low-pressure casting and detection device, applied in the direction of measuring device, measuring fluid pressure, instrument, etc., can solve the problems of increasing production cost, wasting metal liquid, increasing energy consumption, etc., and achieving the effect of reducing production cost and saving metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 Take the SF6 switchgear shell as an example:

[0028] The shape of this product is a straight cylinder plus two side flanges, the diameter is Φ550mm, the shell height is 1015mm, the wall thickness δ is 26-34mm, and the pressure to be borne during work is 580KPa. Its low-pressure casting process setting parameters are filling pressure 0-100KPa, filling time is 40s, holding pressure is 100KPa, holding time is 20 minutes, and the pressure is controlled at 100 (1±0.5%) KPa during the pouring process According to statistics, from January 1, 2010 to the present, a total of 1,500 pieces of casting products were cast, and 37 pieces were scrapped due to casting defects, with a pass rate of 97.53%.

Embodiment 2

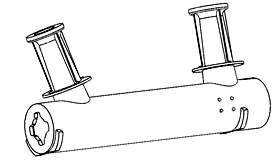

[0029] Embodiment 2 takes the circuit breaker housing as an example:

[0030] This product has a slender main pipe with two branch pipes, the wall thickness is very thin, the diameter of the main pipe is Φ300mm, the diameter of the branch pipe is Φ253mm, the length of the shell is 1807mm, and the wall thickness δ of the branch pipe and the main pipe is only 9-10mm. It is 650KPa. Since the wall thickness is relatively thin, it requires high casting quality to bear the pressure. Its low-pressure casting process setting parameters are filling pressure 0-100KPa, filling time is 45s, holding pressure is 100KPa, holding time is 18 minutes, and the pressure is controlled at 100 (1±1%) KPa during the pouring process According to statistics, from January 1, 2010 to the present, a total of 2,025 pieces of casting products were cast, and 166 pieces were scrapped due to casting defects, with a pass rate of 91.8%.

Embodiment 3

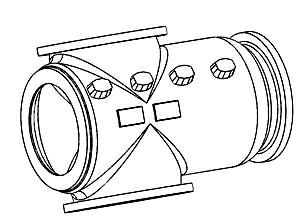

[0031] Embodiment 3 is used for 220KV combined switchgear housing as an example:

[0032] This product has a complex shape, one of the planes has 3 side-by-side flanges, the solidification sequence during casting is not easy to grasp, and casting defects such as pinholes are prone to appear on the flange sealing surface. The diameter of the flange is Φ544mm×3, and the length of the shell is 1665mm, the wall thickness δ is 30mm, and the pressure to be borne during work is 680KPa. Its low-pressure casting process setting parameters are filling pressure 0-100KPa, filling time is 64s, holding pressure is 100KPa, holding time is 25 minutes, and the pressure is controlled at 100 (1±2%) KPa during the pouring process According to statistics, from January 1, 2010 to the present, a total of 324 pieces of casting products were cast, and 39 pieces were scrapped due to casting defects, with a pass rate of 87.96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com