Polyurethane shoe sole stock solution and preparation method thereof

A technology of polyurethane and stock solution, applied in the field of polyurethane, can solve the problems of low physical properties such as sole elasticity and folding resistance, strict restrictions on the use of formulas, and inflexible adjustment of formulas, and achieve good application value. The preparation method is simple and easy to implement. good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

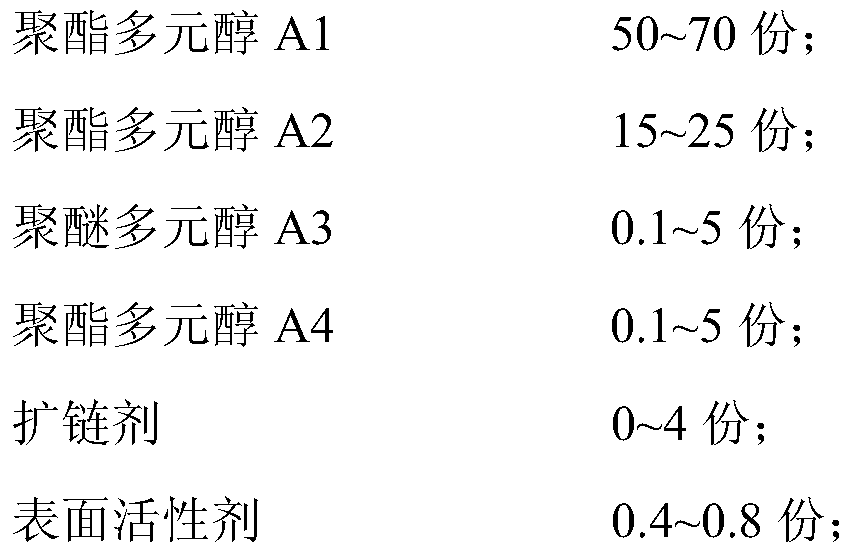

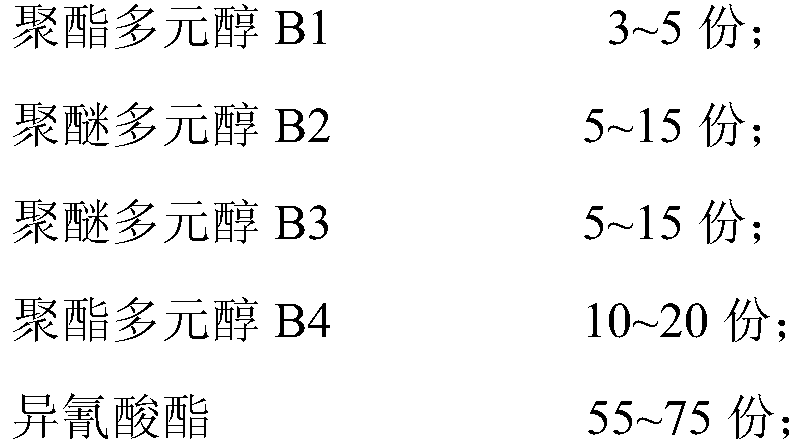

Method used

Image

Examples

Embodiment 1

[0041] The polyurethane sole stock solution provided by the present embodiment is prepared by the following method:

[0042] (1) Preparation of component A:

[0043] Weigh 69.3kg for CMA-244, 20.0kg for MX-806, 5.0kg for PM-445, 5kg for KE-220, 0.3kg for B8952 and 0.4kg for B8300. Put the weighed CMA-244, PM-445, MX-806 and KE-220 into the reaction kettle for stirring, then put in B8952 and B8300 respectively, stir fully at 55°C for 3 hours, put them into barrels after passing the inspection, and keep them sealed Get A component.

[0044] (2) Preparation of component B:

[0045] Put 10.0kg of ED-28, 10kg of CHE-822P, 13kg of CMA-244 and 5.0kg of MX-2325 into the reaction kettle in turn, start stirring and raise the temperature to 75°C, vacuumize to -0.098MPa, dehydrate and degas For 2.0 hours, cool down to 40°C for phosphoric acid (accounting for 0.001% of the total weight of component B) and 58kg of MDI and 5kg for MDI-100LL, raise the temperature to 75°C for 3.0 hours, cool...

Embodiment 2

[0049] The polyurethane sole stock solution provided by the present embodiment is prepared by the following method:

[0050] (1) Preparation of component A:

[0051] Weigh 65.8kg for CMA-244, 20.0kg for MX-806, 5.0kg for PM-445, 5kg for KE-220, 3.5kg for EG, 0.3kg for B8952 and 0.4kg for B8300. Put the weighed CMA-244, PM-445, MX-806 and KE-220 into the reaction kettle for stirring, then put in EG, B8952 and B8300 respectively, stir fully at 55°C for 3 hours, and fill the tank after passing the inspection. Sealed and preserved to obtain component A;

[0052] (2) Preparation of component B:

[0053] Put 10.0kg of ED-28, 10kg of CHE-822P, 13kg of CMA-244 and 5.0kg of MX-2325 into the reaction kettle in turn, start stirring and raise the temperature to 75°C, vacuumize to -0.098MPa, dehydrate and degas For 2.0 hours, cool down to 40°C for phosphoric acid (accounting for 0.001% of the total weight of component B) and 58kg of MDI and 5kg for MDI-100LL, raise the temperature to 75...

Embodiment 3

[0057] The polyurethane sole stock solution provided by the present embodiment is prepared by the following method:

[0058] (1) Preparation of component A:

[0059] Weigh POL-2356 65.6kg, MX-806 20.0kg, PM-445 5.0kg, DP-4002E 5kg, EG 3.7kg, B8952 0.3kg and B8300 0.4kg. Put the weighed CMA-244, PM-445, MX-806 and DP-4002E into the reaction kettle for stirring, then put in EG, B8952 and B8300 respectively, and fully stir at 55°C for 3 hours, after passing the inspection, put them into barrels, Sealed and preserved to obtain component A;

[0060] (2) Preparation of component B:

[0061] Put 10.0kg of DP-4000E, 10kg of CHE-822P, 13kg of CMA-244 and 5.0kg of MX-2325 into the reaction kettle in turn, start stirring and raise the temperature to 75°C, vacuumize to -0.098MPa, dehydrate and degas For 2.0 hours, cool down to 40°C for phosphoric acid (accounting for 0.001% of the total weight of component B) and 58kg of MDI and 5kg for MDI-100LL, raise the temperature to 75°C for 3.0 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com