Continuous polymerization production method of petroleum resin

A petroleum resin and production method technology, applied in the field of continuous polymerization production of petroleum resin, can solve the problems of unsuitability for large-scale industrial production, low degree of automation, high labor intensity, etc., to maintain stability, increase efficiency, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

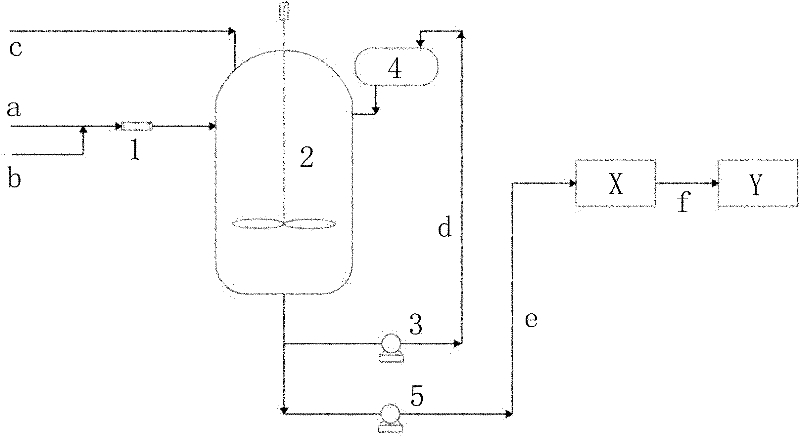

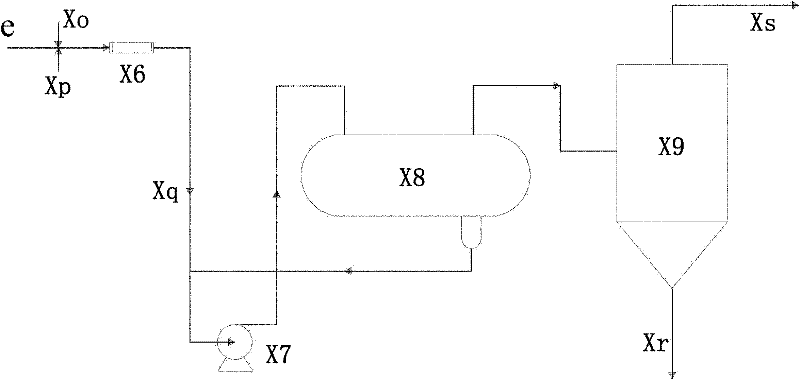

[0036] The raw materials are C5 fraction (a) and C9 fraction (b) with a mass ratio of 1:1.5, after being pre-mixed by a static mixer (1), they enter the polymerization reactor (2) continuously from the side of the kettle, and the catalyst solution (c) continuously flows from The tank top enters the reactor, and the catalyst is 0.2wt% of the mixed material liquid. Stir in the polymerization tank to mix the feed liquid, polymerize at a temperature of 45°C, and circulate the polymerization feed liquid (d) into the condenser (4) through the circulating pump (3) connected to the bottom of the tank to condense and return to the reactor Continuing polymerization, circulation pump (3) flow rate is 10m 3 / h. The flow rate of the extraction pump (5) at the bottom of the kettle is controlled at 70m 3 / h, continuous extraction of polymer feed liquid (e). The extracted polymer liquid (e) is subjected to continuous alkali washing to complete alkali washing, slag removal and water washing...

Embodiment 2

[0038] The raw materials are C5 fraction (a) and C9 fraction (b) with a mass ratio of 1:1. After being pre-mixed by a static mixer (1), they enter the polymerization reactor (2) continuously from the tank side, and the catalyst solution (c) continuously flows from The tank top enters the reactor, and the catalyst is 0.4wt% of the mixed material liquid. Stir in the polymerization tank to mix the feed liquid, polymerize at a temperature of 60°C, and circulate the polymerization feed liquid (d) into the condenser (4) through the circulating pump (3) connected to the bottom of the tank to condense and return to the reactor Continuing polymerization, circulation pump (3) flow rate is 15m 3 / h. The flow rate of the extraction pump (5) at the bottom of the kettle is controlled at 80m 3 / h, continuous extraction of polymer feed liquid (e). The extracted polymer liquid (e) is subjected to continuous alkali washing to complete alkali washing, slag removal and water washing (X). The ...

Embodiment 3

[0040] The raw materials are C5 fraction (a) and C9 fraction (b) with a mass ratio of 1.5:1. After being pre-mixed by a static mixer (1), they enter the polymerization reactor (2) continuously from the side of the kettle, and the catalyst solution (c) continuously flows from The tank top enters the reactor, and the catalyst is 0.8wt% of the mixed material liquid. Stir in the polymerization tank to mix the feed liquid, polymerize at a temperature of 80°C, and circulate the polymerization feed liquid (d) into the condenser (4) through the circulation pump (3) connected to the bottom of the tank to condense and return to the reactor Continuing polymerization, circulation pump (3) flow rate is 20m 3 / h. The flow rate of the extraction pump (5) at the bottom of the kettle is controlled at 90m 3 / h, continuous extraction of polymer feed liquid (e). The extracted polymer material (e) is subjected to continuous alkali washing to complete alkali washing, slag removal and water washin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| color hue | aaaaa | aaaaa |

| bromine number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com