Mechanical preventing and controlling additive for anabasine pesticide and production method thereof

A production method and technology for pesticides, applied in pesticides, biocides, botanical equipment and methods, etc., can solve problems such as coarse particle size, low water consumption for aerial spraying, and adhesion, and achieve improved stability and convenience. The effect of shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

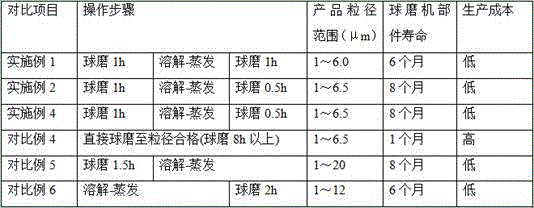

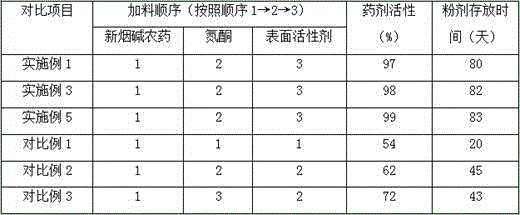

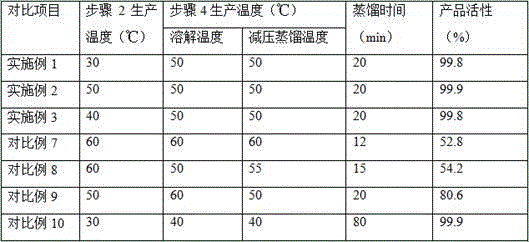

Examples

Embodiment 1

[0023] Example 1: A mechanized control aid for neonicotinoid pesticides and insecticides, the mechanized control aids are wettable powders with a particle size of 1.0 to 6.5 μm, and the dosage of neonicotinoid pesticides and insecticides is 5 kg , the consumption of batching 100kg, wherein the percentage content of each component in the batching is as follows: sodium dodecyl sulfonate 5 kg, nonionic and anionic compound surfactant 12.5 kg, antioxidant 0.5 kg, azone 3.25kg, Dispersant: sodium lignosulfonate, calcium lignosulfonate 1.25 kg, sodium carboxymethyl starch 2.5 kg and filler: white carbon black and kaolin 75 kg.

Embodiment 2

[0024] Example 2: A mechanized control aid for neonicotinoid pesticides and insecticides, the mechanized control aids are wettable powders with a particle size of 1.0 to 6.5 μm, and the dosage of neonicotinoid pesticides and insecticides is 70 kg , the dosage of ingredients is 100kg, wherein the percentage content of each component in the ingredients is as follows: 10 kg of sodium dodecylsulfonate, 8 kg of nonionic and anionic compounded surfactants, 3 kg of antioxidants, 4 kg of azone, Dispersant: potassium oleate, sodium oleate 10 kg, sodium carboxymethyl starch 8 kg and filler: kaolin 58 kg.

Embodiment 3

[0025] Example 3: A mechanized control aid for neonicotinoid pesticides and insecticides, the mechanized control aids are wettable powders with a particle size of 1.0 to 6.5 μm, and the dosage of neonicotinoid pesticides and insecticides is 15 kg , the dosage of ingredients is 100kg, wherein the percentage content of each component in the ingredients is as follows: 6 kg of sodium dodecyl sulfonate, 12 kg of non-ionic and anionic compounded surfactants, 2.4 kg of antioxidants, 4.6 kg of azone, dispersed Agent: alkyl polyoxyethylene ether iodate, alkylphenol polyoxyethylene ether formaldehyde condensate 5 kg, sodium carboxymethyl starch 6 kg and filler: white carbon black 64 kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com