Lightweight aluminum coated sheet strip and production method thereof

A production method, the technology of aluminum-clad plate, applied in the direction of metal rolling, etc., can solve the problem of not solving the heat dissipation problem of the wheel, not including the performance of the substrate composition, and cannot be produced with structural parts, so as to solve the problem of poor heat dissipation and good interface bonding characteristics , excellent plastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] According to the chemical composition requirements of the aluminum-clad substrate involved in the present invention, steel strips 1 and 0.2mm aluminum strips 2 of different specifications are selected for single-layer compounding, see figure 1 , Rolling at room temperature after surface cleaning and grinding. The chemical composition of the aluminum-clad substrate is shown in Table 1. The aluminum-clad strip is bell-type annealed, and the thickness of the finished product is 0.3-4mm. The properties of the finished product are shown in Table 2.

Embodiment 2

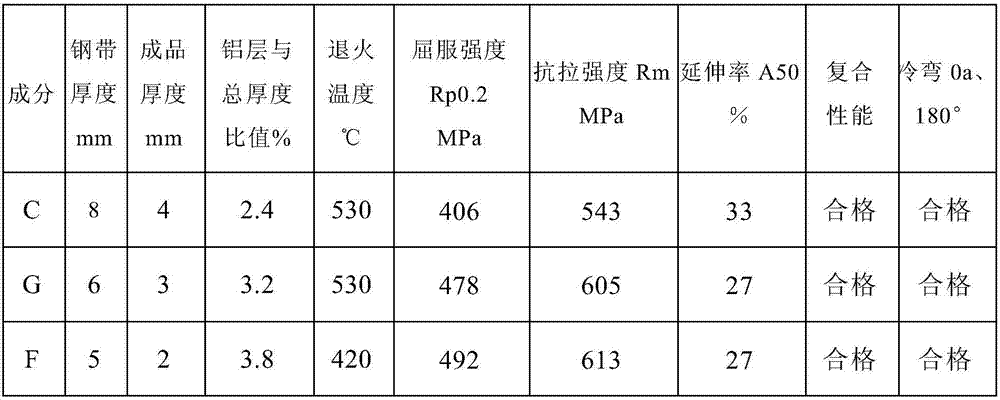

[0042] According to the chemical composition requirements of aluminum-clad substrates in Table 1, steel strips 1 and 0.2mm aluminum strips 2 of different specifications are selected for double-layer compounding, see figure 2 , Rolling at room temperature after surface cleaning and grinding. The thickness of the finished product is 0.3-4mm, and the performance of the finished product is shown in Table 3.

[0043] The yield strength of the aluminum-clad steel strip in the examples obtained according to the design scope of the steel grade composition and the rolling process control technology of the present invention exceeds 400MPa, the tensile strength is 500-800MPa, and the elongation is above 18%. The steel-aluminum interface bonding performance is excellent, and has Good cold bending and stamping performance. It can be applied to the production of boxes with heat dissipation requirements such as lightweight wheels, radiator parts and corrosion resistance requirements. And ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com