Easy-welding low-carbon bainitic steel and manufacturing method thereof

A carbon bainitic steel and bainitic steel technology, applied in the field of easy welding low carbon bainitic steel and manufacturing, can solve the problems of insufficient low temperature toughness, inability to effectively suppress coarse grain boundary ferrite, low ratio and the like , to achieve the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

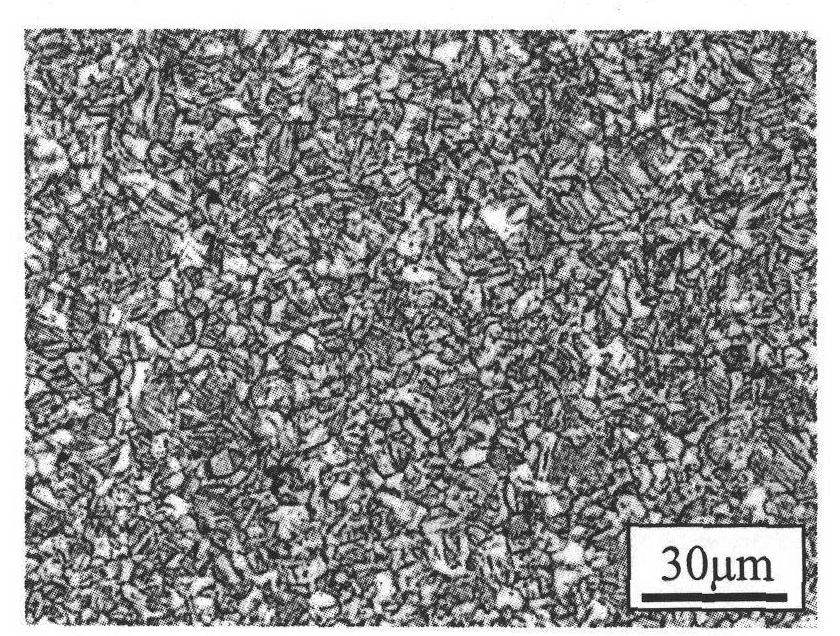

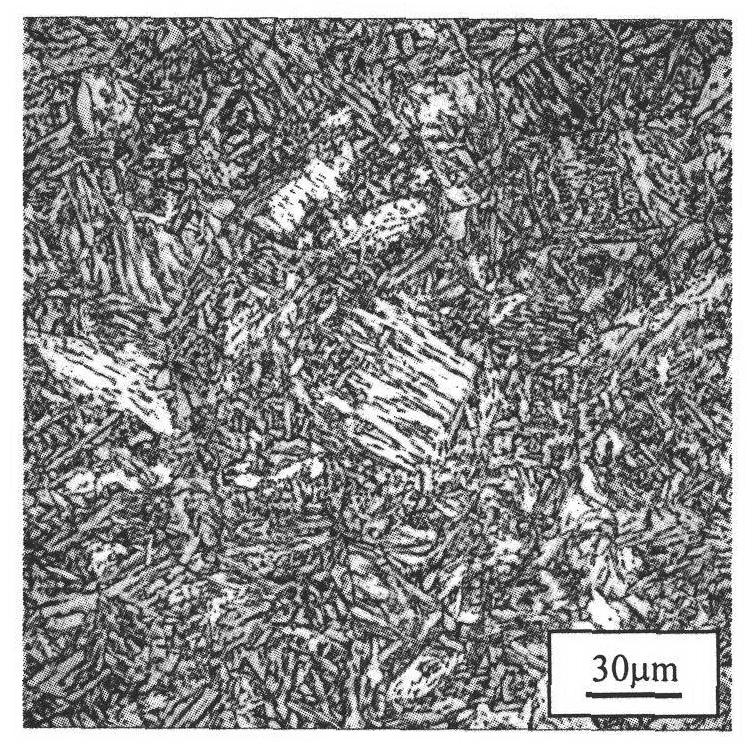

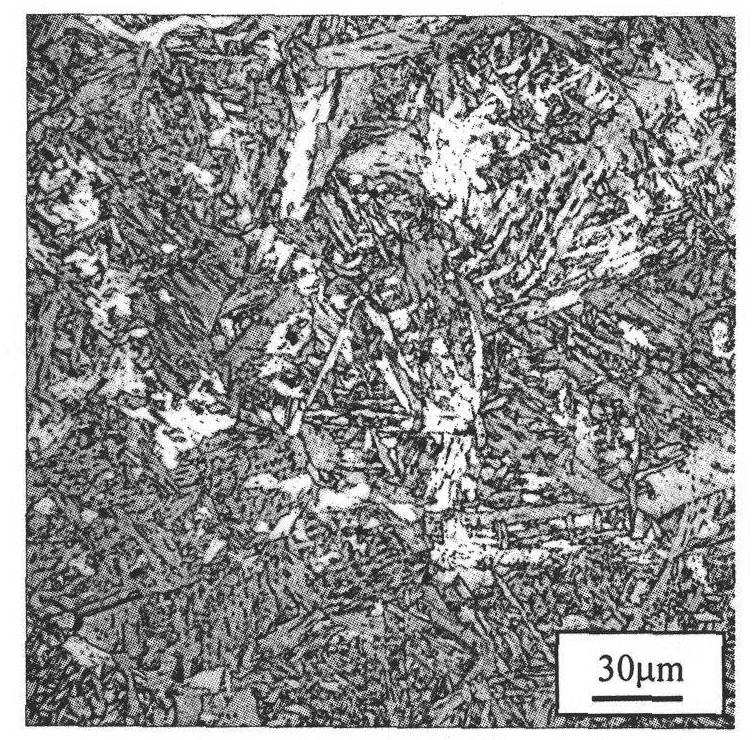

[0047] The easy-to-weld low-carbon bainite steel and its manufacturing method involved in the present invention will be further described in detail below in conjunction with specific examples.

[0048] According to an easy-to-weld low-carbon bainite steel and its manufacturing method described in the present invention, three kinds of test steels with different boron content and nitrogen content were trial-produced as examples. The test steel was smelted in a 150-ton converter. Smelting and continuous casting trial production follow the following process points:

[0049] 1. Add compound deoxidizer and bottom blow argon to carry out pre-deoxidation during the tapping process of converter to ladle;

[0050] 2. At the CAS station, first add aluminum for deep deoxidation, control the aluminum content ≤ 0.035%, and then add vanadium nitrogen alloy and ferroniobium to make the vanadium content, nitrogen content and niobium content in the water close to the target value;

[0051] 3....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com