Bamboo pen container continuous production technology

A production process and pen holder technology, applied in the continuous production process of bamboo pen holders, can solve the problems of low manual production efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

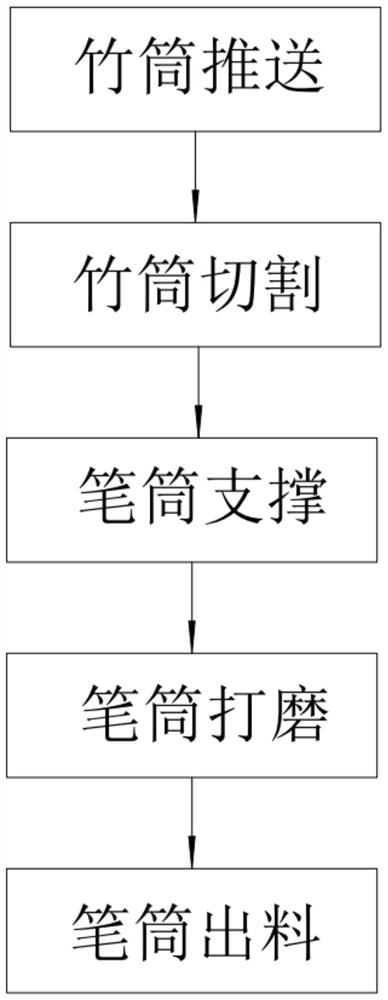

[0043] like figure 1 Shown, a kind of continuous production technique of bamboo pen container comprises the following steps:

[0044] Step 1: push the bamboo tube, the fixing component 21 fixes one end of the bamboo tube 6 and pushes the bamboo tube 6 forward so that the other end enters the installation component 41;

[0045] Step 2: Cutting the bamboo tube. After step 1, the bamboo joints in the bamboo tube 6 are in conflict with the limit assembly 421, and the limit assembly 421 drives the two groups of cutting heads 430 symmetrically arranged on both sides to move to the middle position and contact with the limit assembly 421. The outer wall of the bamboo tube 6 collides, and then the drive assembly 51 drives the installation assembly 41 to rotate, and the cutting head 430 cuts the bamboo tube 6 to obtain a pen holder 61;

[0046] Step 3: Supporting the pen container. After step 2, the drive assembly 51 drives the pen container 61 and the installation assembly 41 to move ...

Embodiment 2

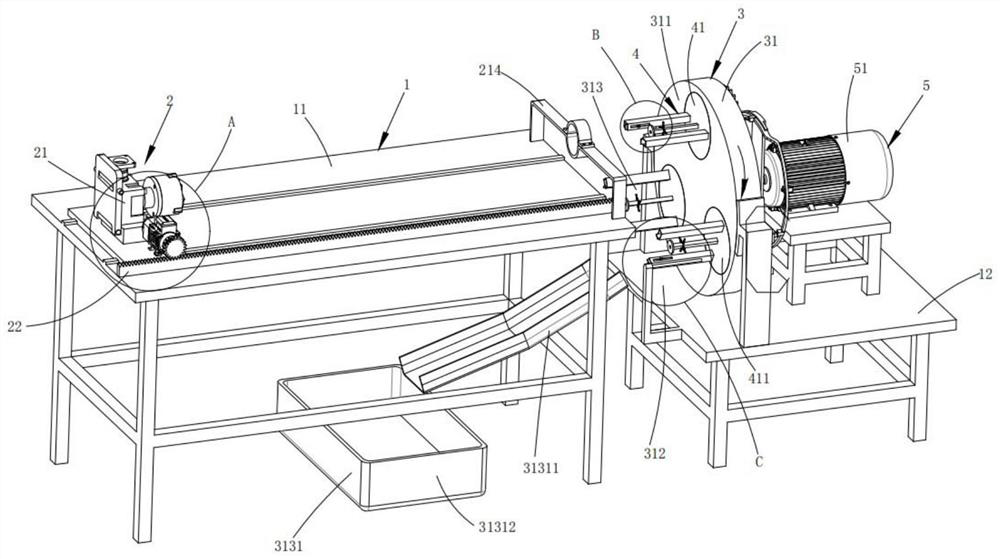

[0059] The present invention also provides a kind of bamboo pen container continuous processing equipment:

[0060] like Figure 2 to Figure 5 Shown, a kind of bamboo pen container continuous processing equipment comprises:

[0061] Workbench 1, which includes a main workbench 11 and an auxiliary workbench 12 arranged on one side of the main workbench 11;

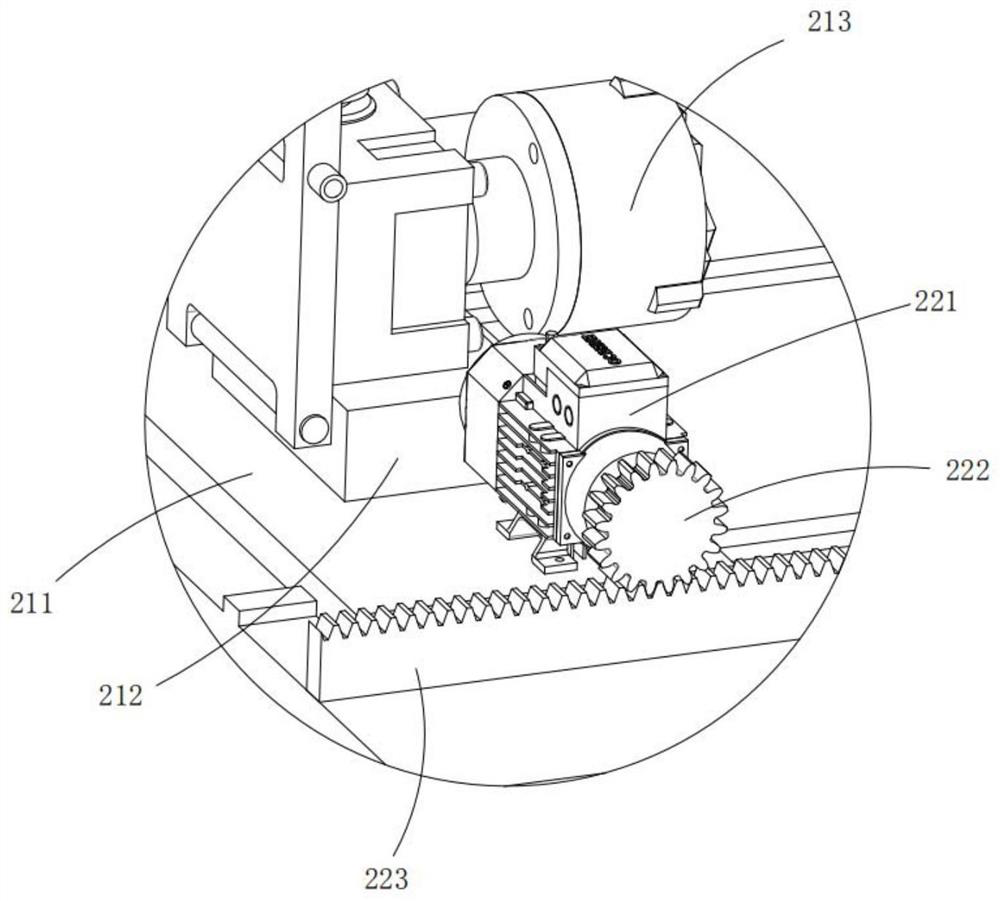

[0062] The feeding device 2, the feeding device 2 includes a fixed assembly 21 slidably arranged on the main worktable 11 left and right and rotatable, and a power assembly 22 that drives the fixed assembly 21 to move;

[0063] Rotating device 3, said rotating device 3 comprises a rotating disc 31 rotatably mounted on said auxiliary workbench 12, and said rotating disc 31 is provided with a cutting station 311, a grinding station 312 and a blanking station in sequence along its rotating direction 313, the cutting station 311 is set facing the fixed assembly 21; the grinding station 312 includes a polishing assembly 3121 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com