Patents

Literature

41results about How to "Reduce slagging rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-slagging biomass solid granular fuel

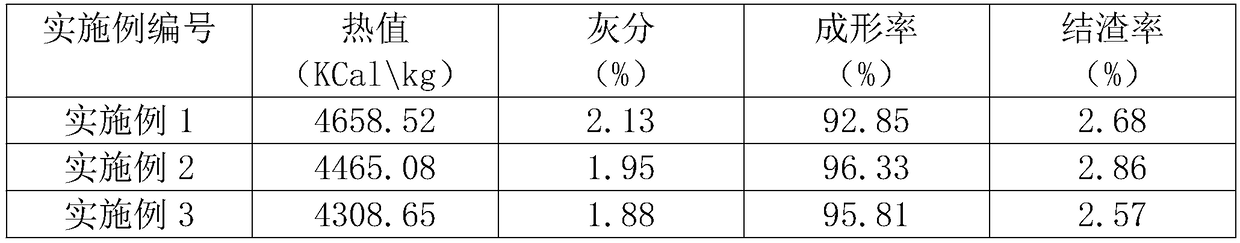

The invention discloses an anti-slagging biomass solid granular fuel and solves a problem that a biomass solid granular fuel in the prior art is liable to slag and is low in combustion efficiency. The anti-slagging biomass solid granular fuel is prepared from following raw materials, by weight, 60-70 parts of crop straws, 10-15 parts of wood chips, 5-10 parts of bagasse, 3-5 parts of a combustion-promoting agent and 1-3 parts of an anti-slagging agent. The anti-slagging biomass solid granular fuel is simple in components, reasonable in formula, low in cost, high in combustion efficiency and low in slagging rate.

Owner:江山华隆能源开发有限公司

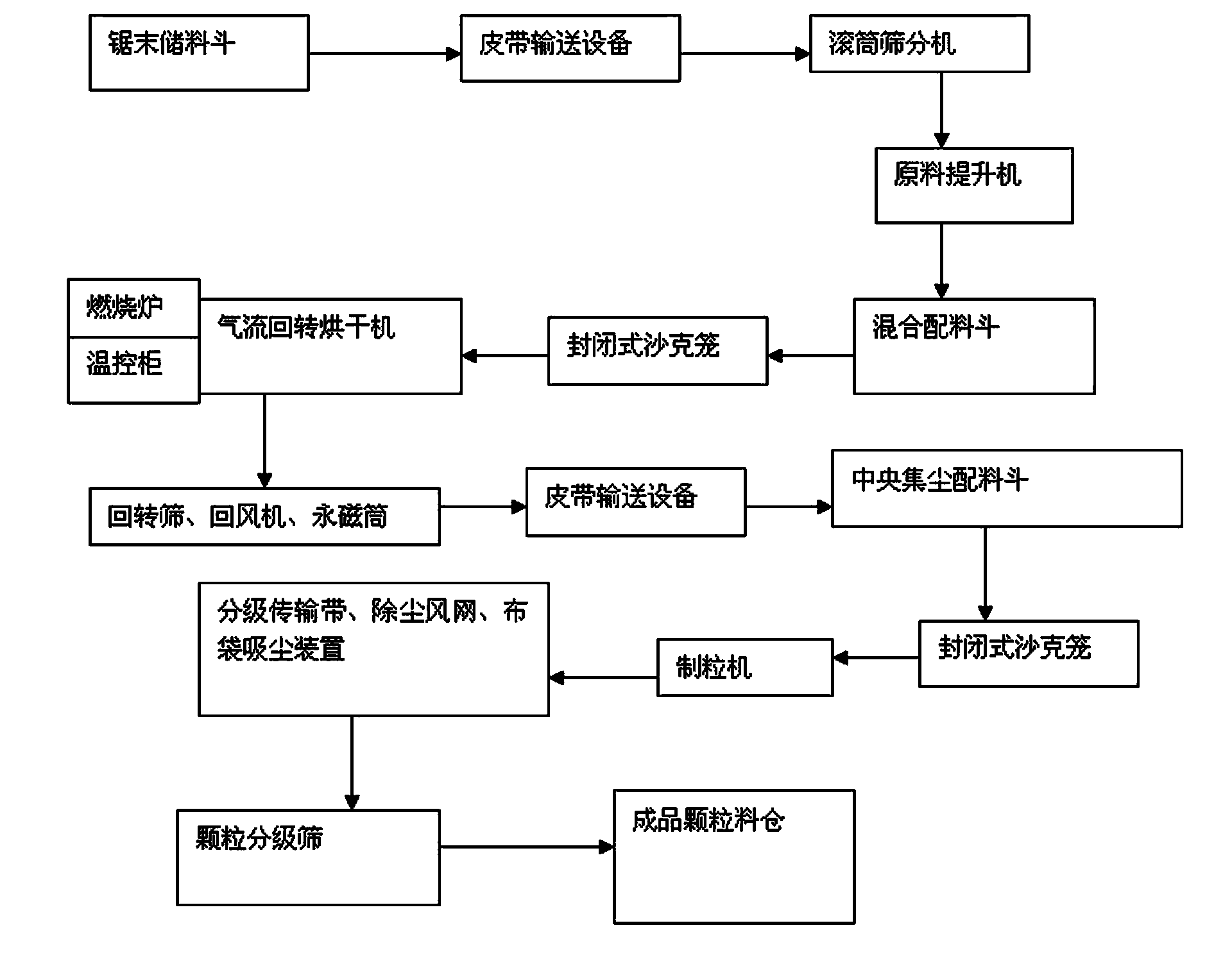

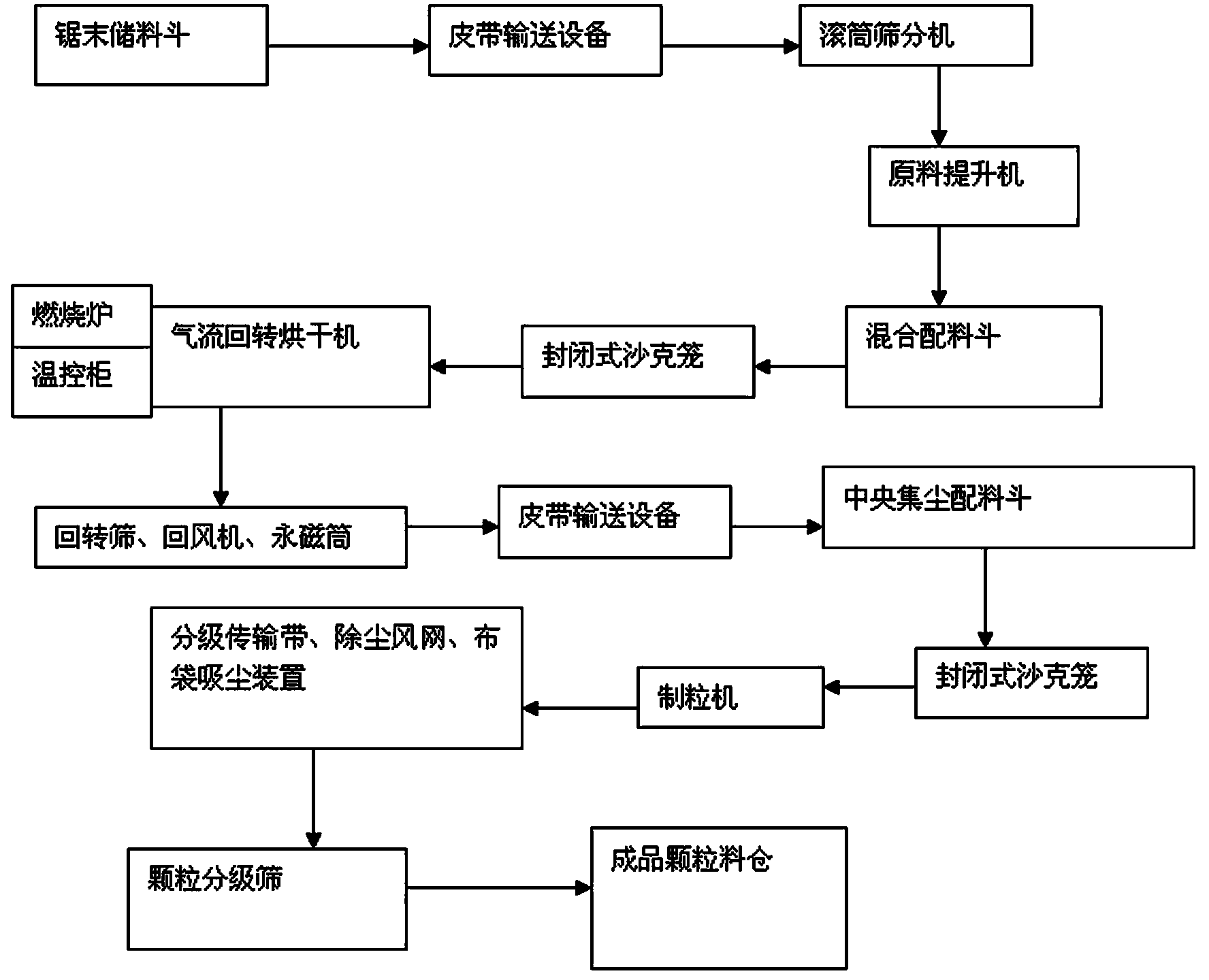

Production technique of pure cedar biomass granular fuel

The invention relates to a production technique of a pure cedar biomass granular fuel, which comprises the following steps: screening cedar sawdust, mixing materials, drying, cooling, carrying out secondary mixing on the mixture and cedar shavings, and granulating to obtain the finished product. The technique provided by the invention has the advantages of simpleness, less generated dust, high forming ratio and high yield; and the prepared biomass granular fuel has the advantages of high heating value, low slagging tendency, wide raw material resources and low production cost.

Owner:蓬溪县天桥木业有限公司

Preparation method of biomass particle carbon

InactiveCN107365615ABurn completelyImprove combustion efficiencyBiofuelsSolid fuelsCarbonizationSulfide

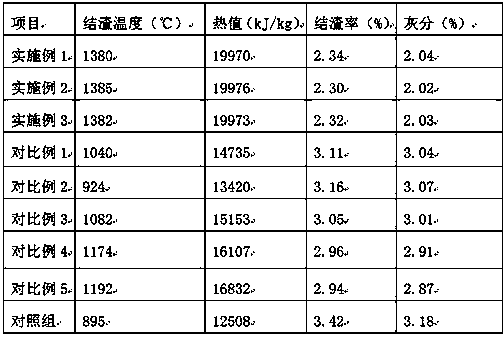

The invention relates to the technical field of biomass fuel and aims at providing a preparation method of biomass particle carbon with a high calorific value and a low clinkering rate. The preparation method of the biomass particle carbon is characterized by comprising the following steps of: raw material pretreatment, extrusion forming and carbonization refining, wherein the carbonization refining is to heat a biomass particle after the extrusion forming under an air isolated condition, carbonize the biomass particle and remove impurities such as sulfide in the biomass particle; the biomass particle carbon comprises the following raw materials in parts by weight: 20-30 parts of crop straw, 10-20 parts of bagasse, 30-40 parts of bamboo scrap, 80-90 parts of wood chip, 4-5 parts of flame accelerator, and 3-4 parts of anti-slagging agent. The biomass particle carbon prepared by the method has the high calorific value and the low clinkering rate.

Owner:黄山市巨龙生物能源科技有限公司

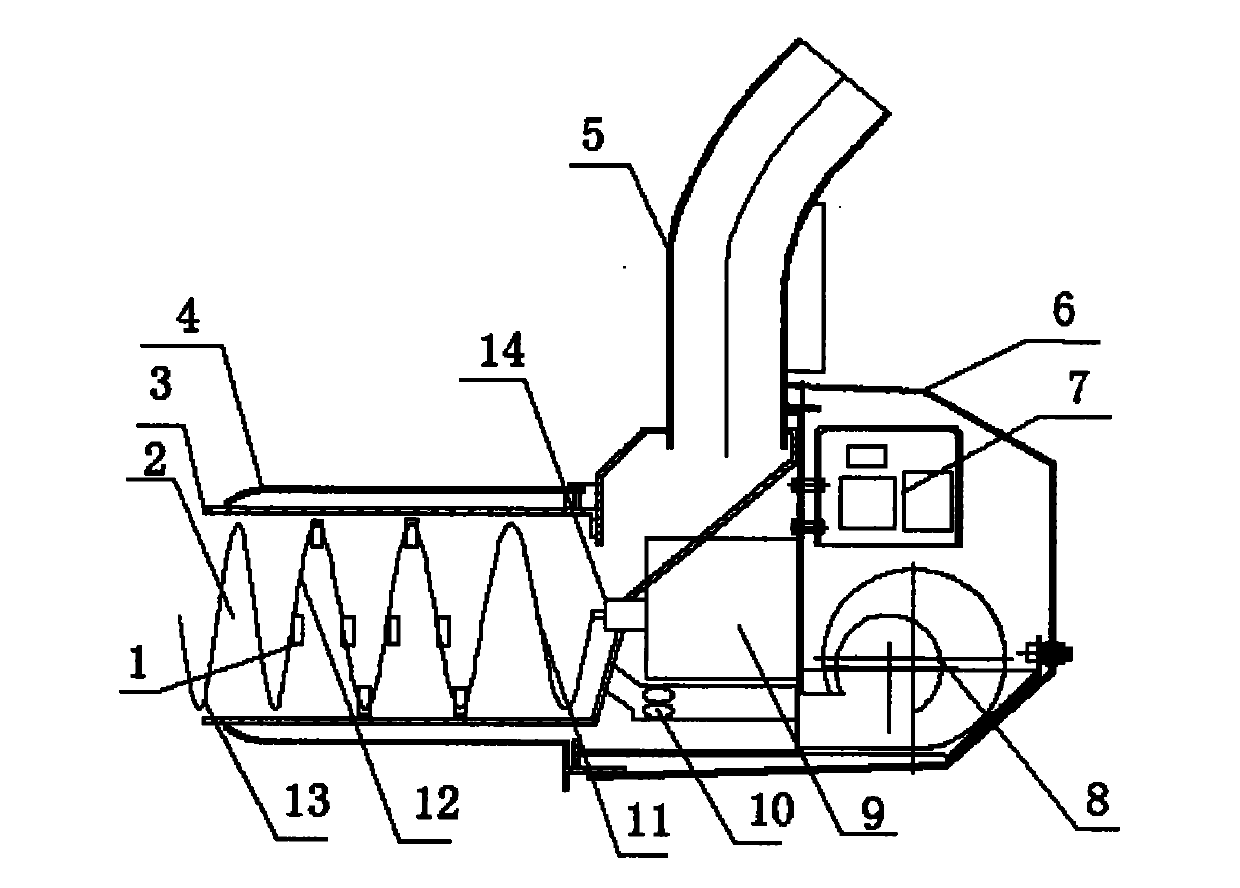

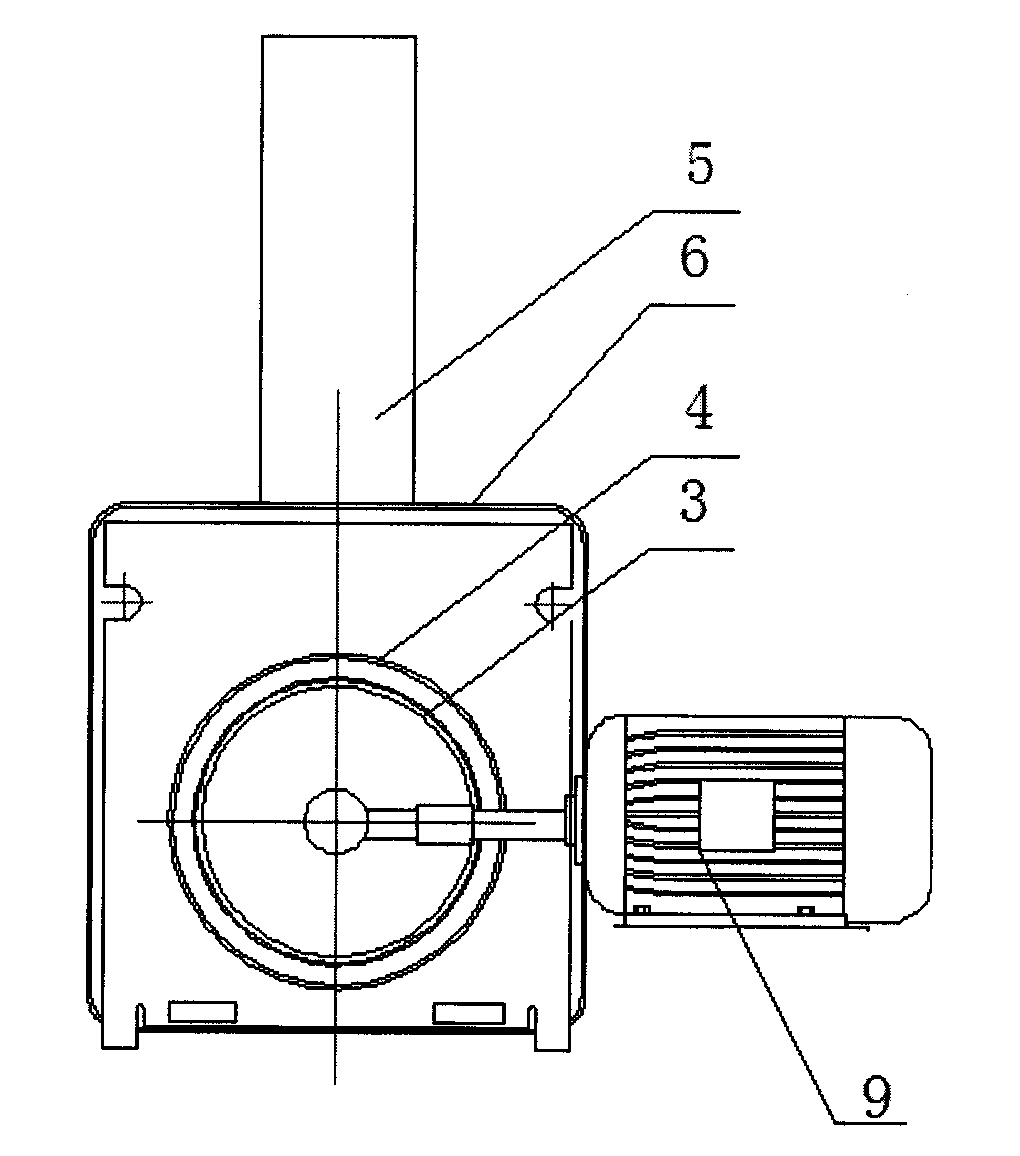

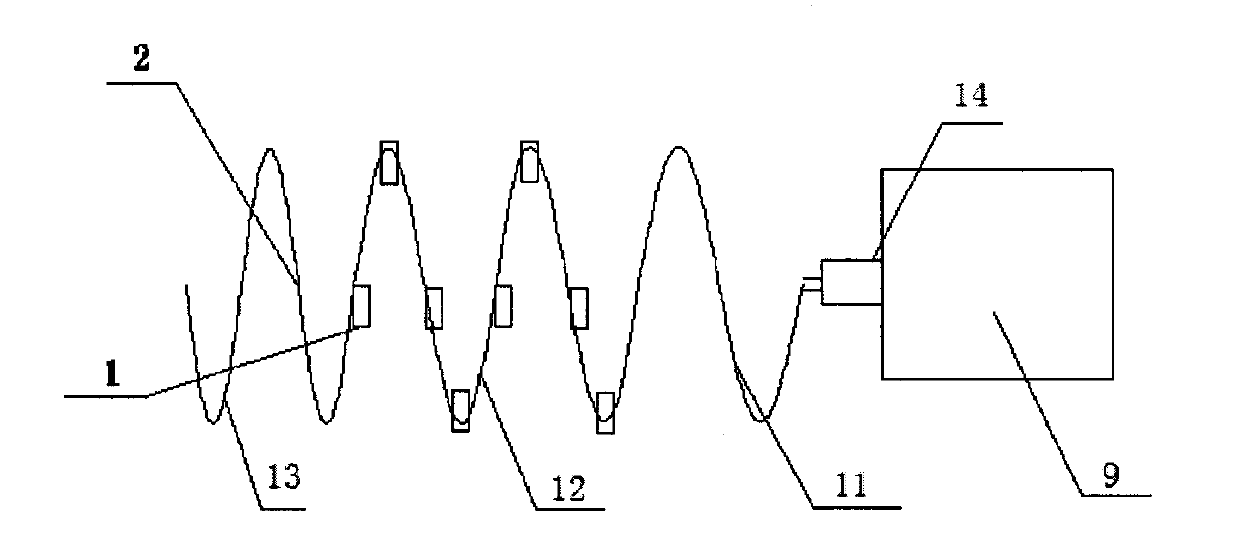

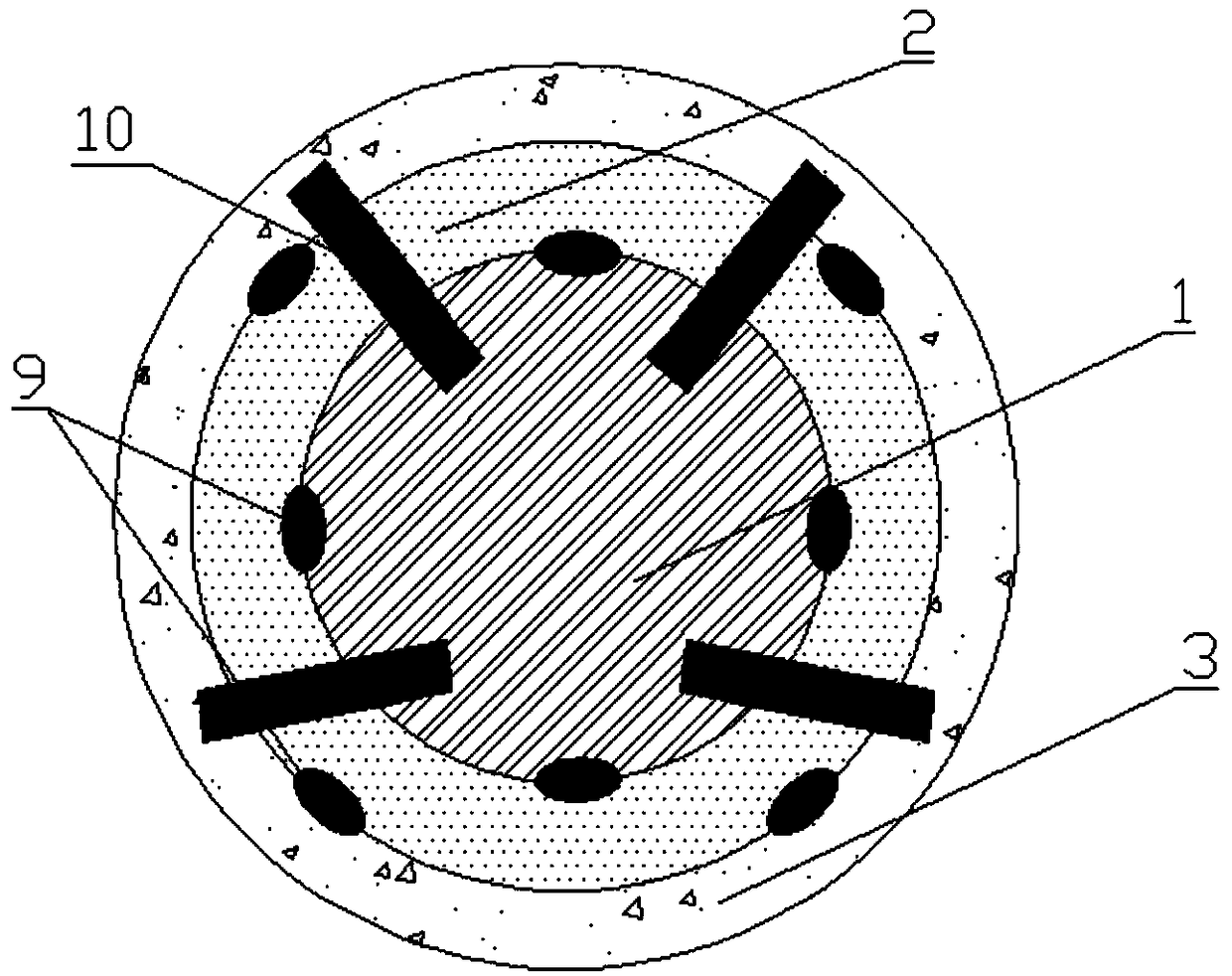

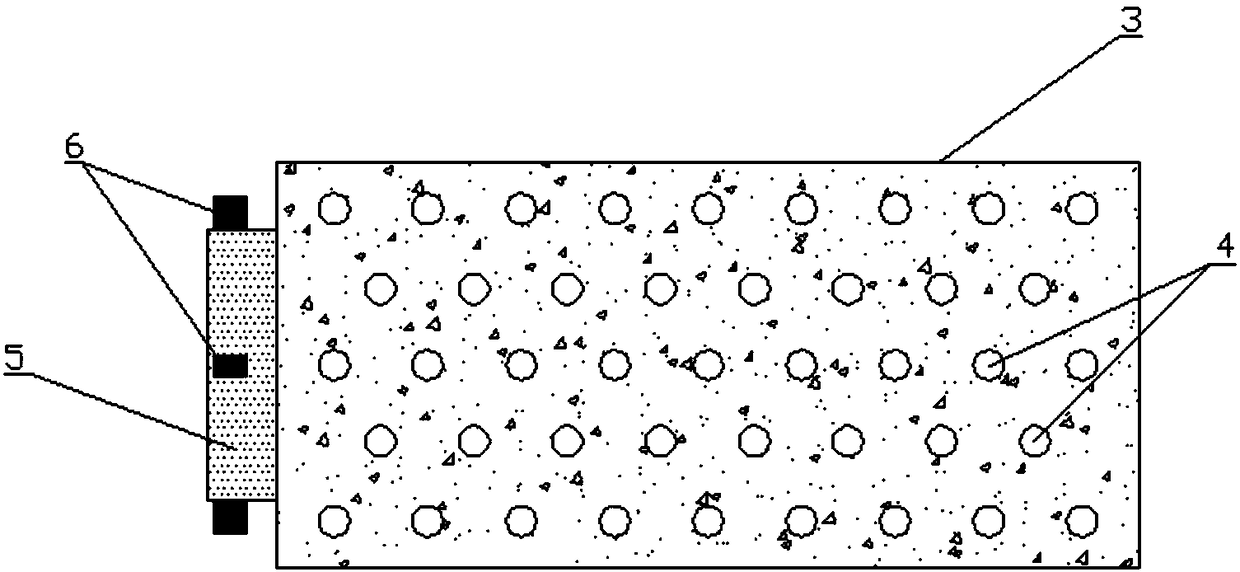

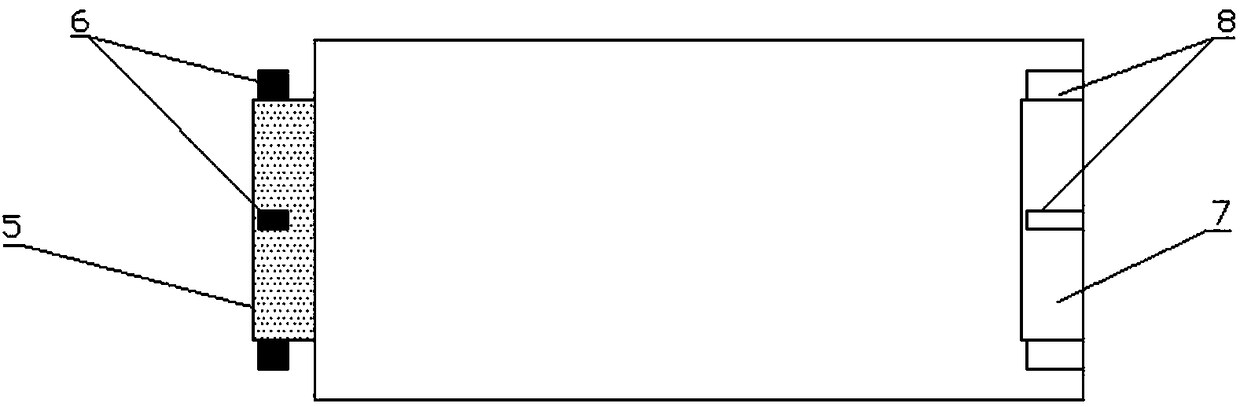

Automatic high-efficient biomass granular fuel combustor

InactiveCN101793391ASolve slaggingReasonable structureSolid fuel combustionCombustion apparatusForest industrySlag

The invention discloses an automatic high-efficient biomass granular fuel combustor, which belongs to the technical field of renewable energy sources. The technical scheme comprises a slag-breaking and ash-removing mechanism (2) and a combustion liner (3), the slag-breaking and ash-removing mechanism (2) which is connected with a motor (9) via a movable port (14) is mounted in the combustion liner (3), and consists of a fuel-pushing screw (11), a combustion stirring screw (12) and an ash-slag discharge screw (13), and different air inlets are arranged at three positions on the cylinder of the combustion liner (3), which correspond to the slag-breaking and ash-removing mechanism (2). The combustor effectively avoids the slagging phenomenon in the process of granular fuel combustion, realizes the granule conveying, stirring, slag breaking, ash removing and the like, increases the combustion efficiency, and is applicable to different types of granular fuels such as crop straws and forestry residues, and the invention provides a guarantee for the promotion of the development of the biomass pellet fuel industry in China.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

Pellet fuel prepared by use of crops straw

InactiveCN104531257AWide variety of sourcesIncrease burn rateBiofuelsSolid fuelsBiotechnologyAdditive ingredient

The present invention relates to the technical field of new energy, and discloses a pellet fuel prepared by use of crops straw, the pellet fuel comprises the following raw materials by weight: 10-15 parts of cotton stalk, 10-15 parts of corn straw, 10-15 parts of peanut shell, 5-10 parts of dahurian larch sawdust, 5-10 parts of rice husk, 5-10 parts of soybean hulls, 3-5 parts of alumina, 3-5 parts of magnesium carbonate, 3-5 parts of calcium carbonate and 3-5 parts of pine oil. The pellet fuel utilizes the abandoned crops as the raw materials, and uses local materials, the product has the characteristics of being energy saving, environmentally-friendly, non renewable resource-saving, and the like, and eases the contradiction of the shortage of electric power and petroleum; the pellet fuel utilizes the crop straw as the main ingredient, is added with suitable amount of additives, is clean and environmentally-friendly, fully uses energy, and makes full use of waste biomass fuels, the raw material source range is wide, combustion rate is high, the pellet fuel is safe to use, and sustainable to use, bottom ash slagging rate is low, and the combustion pollution is less.

Owner:广德县磊淇农副产品废物利用有限公司

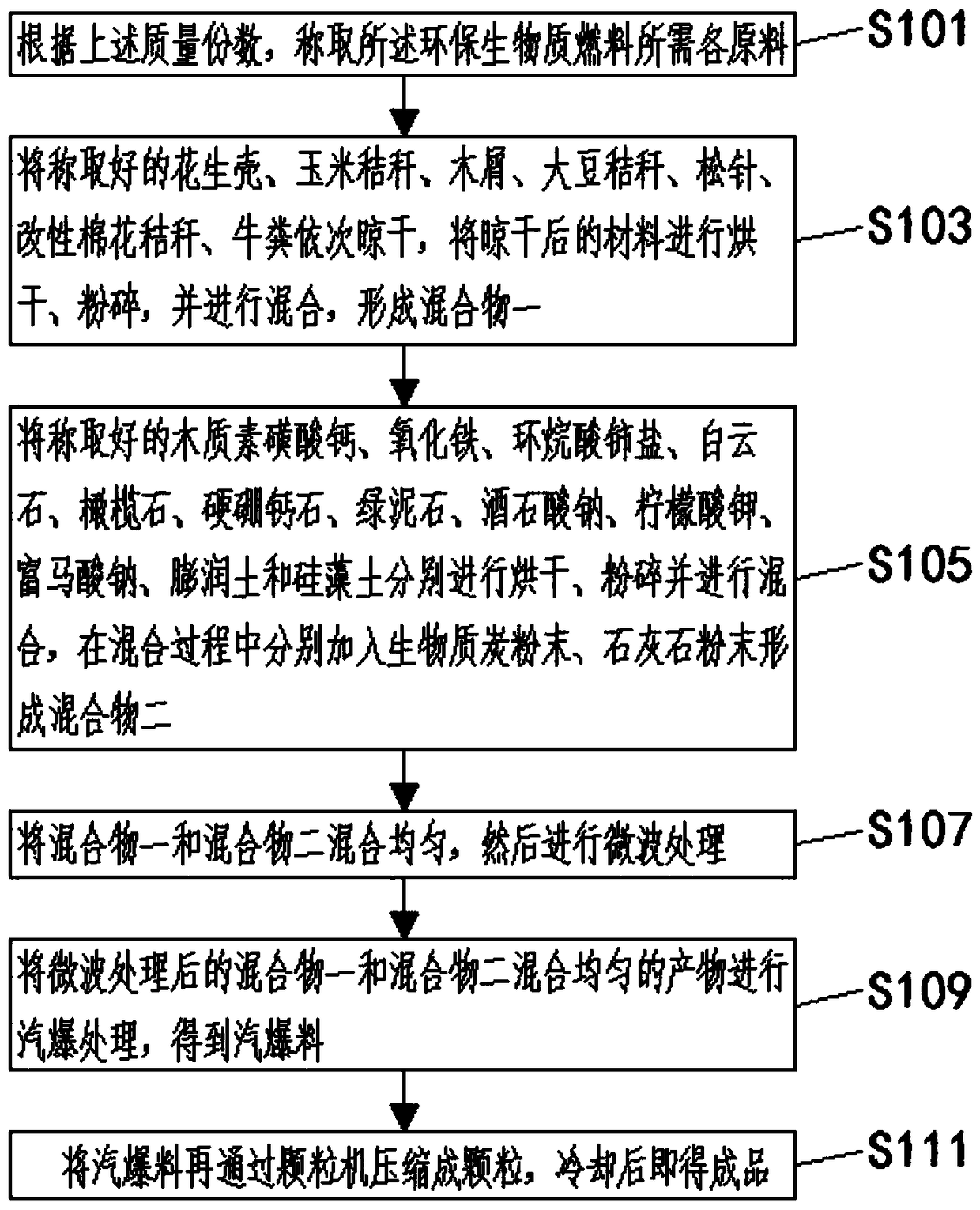

Environment-friendly biomass fuel and preparation method thereof

InactiveCN109370675ASolve the problem of slagging and cokingImprove combustion efficiencyBiofuelsSolid fuelsEnvironmental resistanceBiomass carbon

The invention discloses an environment-friendly biomass fuel and a preparation method thereof. The environment-friendly biomass fuel is prepared from the following raw materials in parts by mass: 2-4parts of calcium lignosulfonate, 20-30 parts of peanut shells, 30-50 parts of corn stalks, 10-20 parts of wood chips, 10-20 parts of biomass carbon powder, 0.2-0.6 part of iron oxide, 3-7 parts of limestone powder, 30-50 parts of soybean stalks, 10-20 parts of pine needles, 10-16 parts of modified cotton stalks, 10-25 parts of cow dung, 5-7 parts of cerium naphthenate, 11-21 parts of an anti-coking additive, 0.4-1.4 parts of a combustion promoter and 12-18 parts of a binder. The environment-friendly biomass fuel has the beneficial effects that the problems of slagging and coking in the combustion process of biomass fuel can be solved, the discharge concentration of SO2 and SO3 in smoke is reduced, atmospheric environment protection is benefited, the combustion efficiency of the biomass fuel is significantly improved, the biomass fuel becomes a high-quality fuel that replaces coal, the combustion performance of the biomass fuel can be improved effectively, and the utilization effect ofthe biomass fuels is greatly promoted; the fuel composition is simple, the compatibility is reasonable, the cost is low, the burning rate is high, and the slagging rate is low.

Owner:梁丰

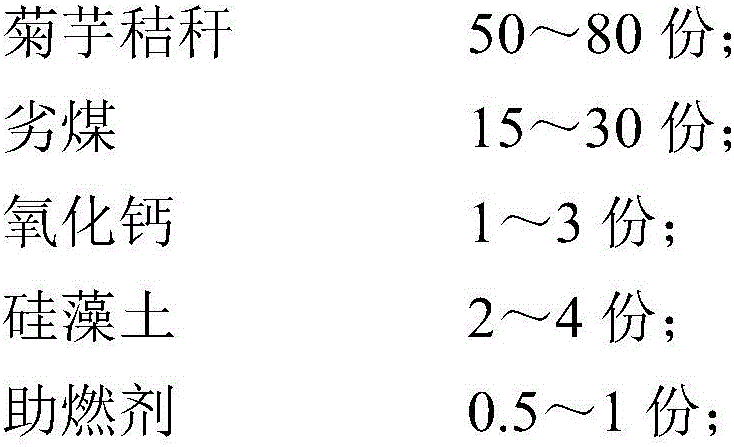

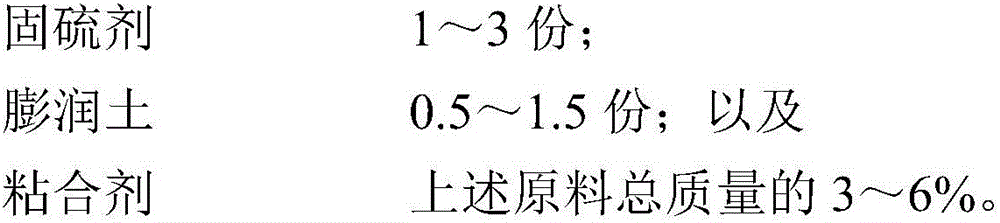

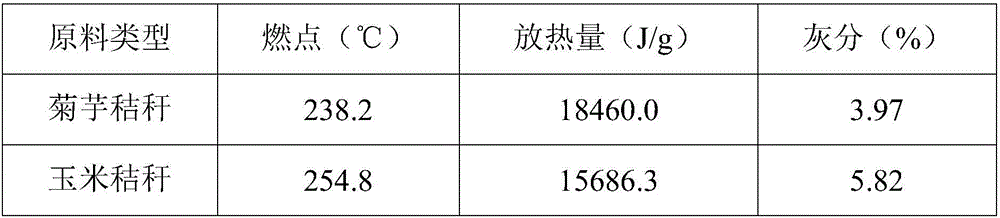

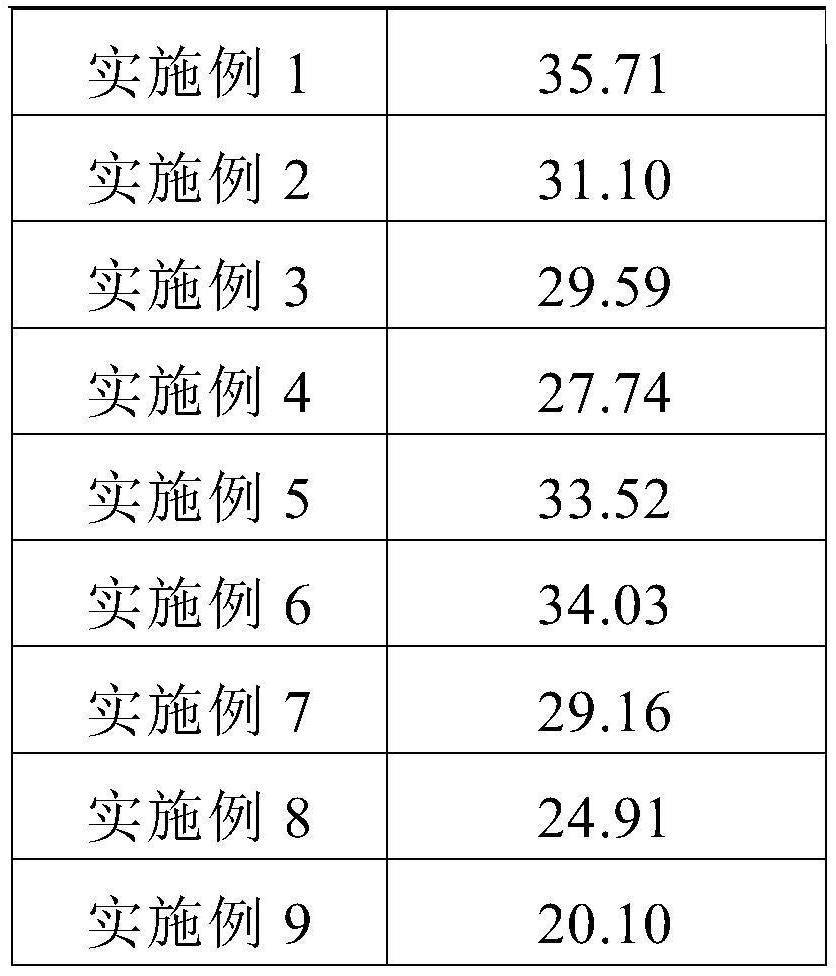

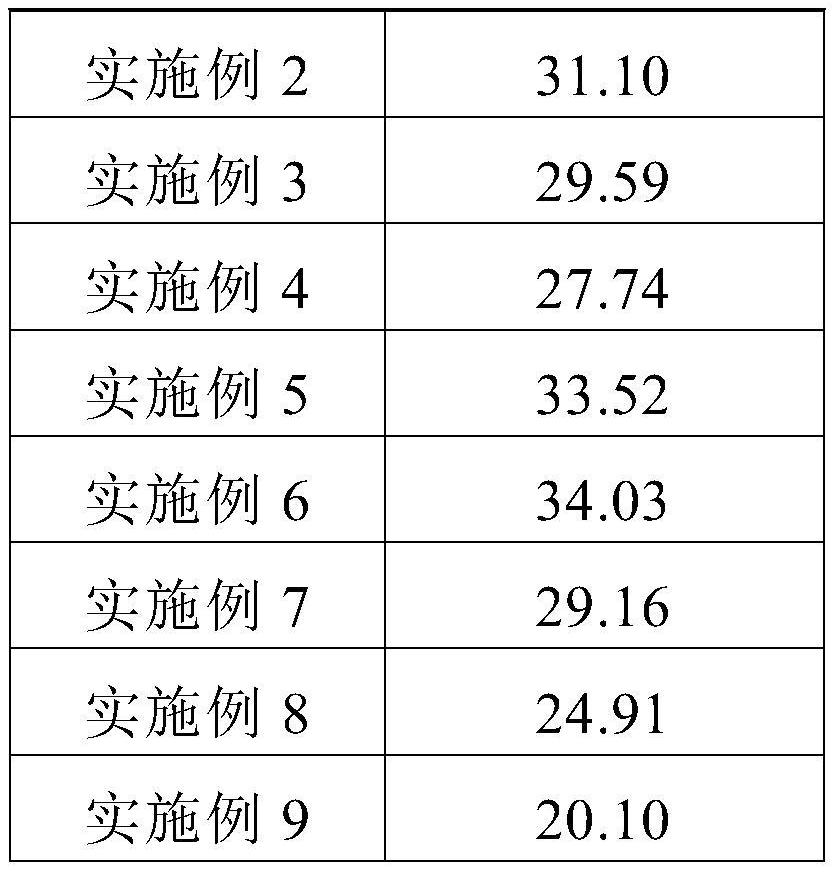

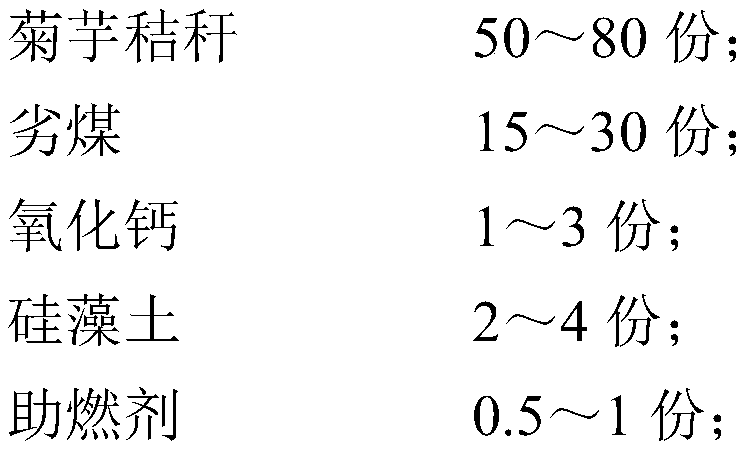

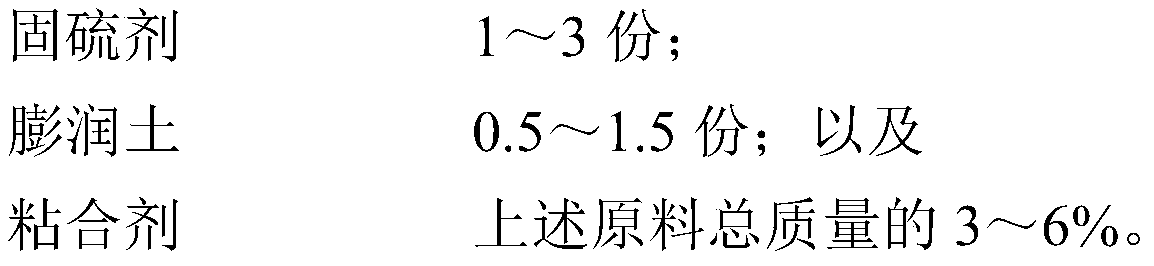

Jerusalem artichoke straw fuel bar and preparing method thereof

The invention discloses a jerusalem artichoke straw fuel bar and a preparing method thereof. The jerusalem artichoke straw fuel bar is prepared from, by weight, 50-80 parts of jerusalem artichoke straw, 15-30 parts of craw coal, 1-3 parts of calcium oxide, 2-4 parts of kieselguhr, 0.5-1 part of combustion improver, 1-3 parts of sulfur-fixing agent and 0.5-1.5 parts of bentonite. The characteristic of high burning caloric value of jerusalem artichoke straw is fully utilized, the combustion supporting component is added to the fuel bar, additives including calcium oxide and kieselguhr are added, the clinkering rate and corrosiveness of jerusalem artichoke straw are reduced, the prepared jerusalem artichoke straw fuel bar can be widely applied to industrial and civilian production, the utilization rate of jerusalem artichoke straw is increased, and extension and development of the jerusalem artichoke industrial chain are promoted.

Owner:山东益得来生物科技有限公司

Preparation method for biomass granular fuel

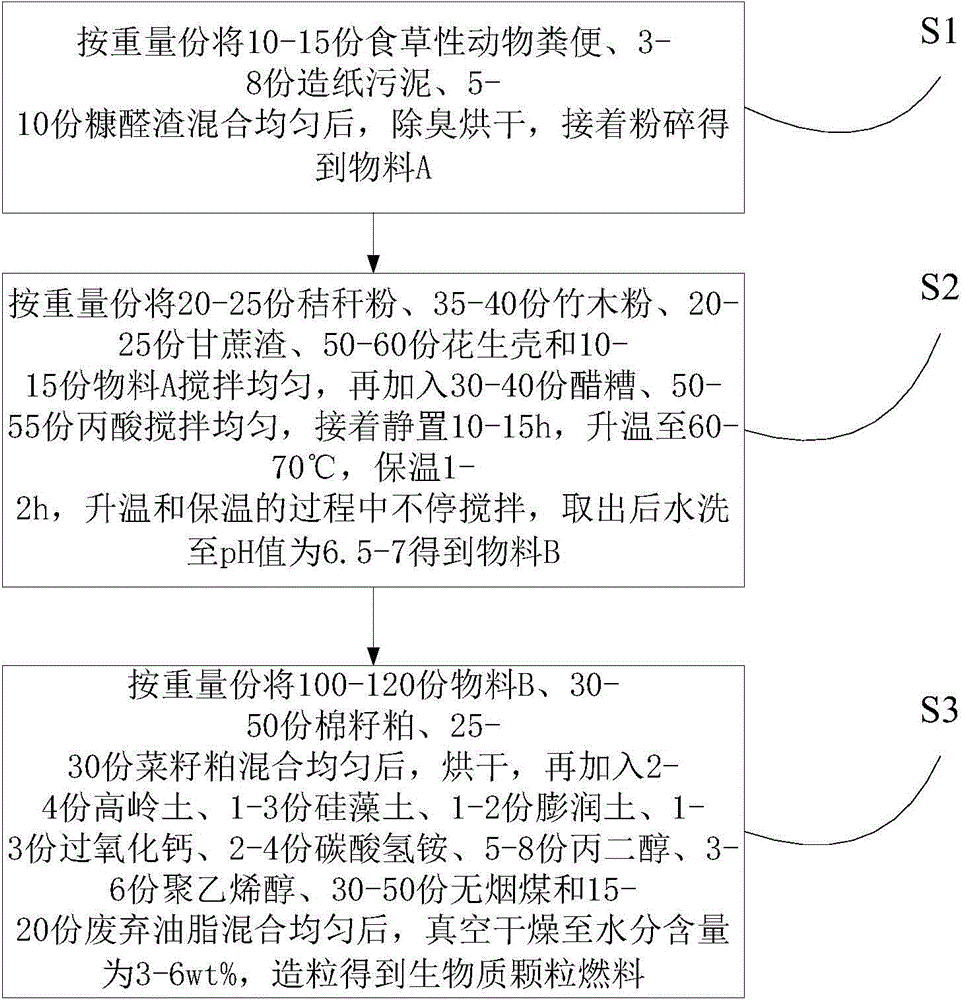

InactiveCN104893779AReduce carbon contentReduce slagging rateBiofuelsSolid fuelsPolyvinyl alcoholPropylene glycol

The invention discloses a preparation method for biomass granular fuel. The preparation method comprises the following steps of: after uniformly mixing herbivorous animal waste, paper mill sludge and furfural residue, deodorizing and drying the mixture and then crushing the mixture to obtain a material A; uniformly stirring straw powder, bamboo powder, bagasse, peanut shells and the material A, then adding vinegar residues and propionic acid to uniformly stir the mixture, then leaving to stand for 10-15 hours, raising the temperature to 60-70 DEG C, insulating the mixture for 1-2 hours, ceaselessly stirring the mixture in the temperature raising and insulating processes, taking out the mixture and washing the mixture till the pH value is 6.5-7 to obtain a material B; and after uniformly mixing the material B, cottonseed meal and rapeseed meal, drying the mixture, then adding kaolin, diatomite, bentonite, calcium peroxide, aluminum hydroxide, propylene glycol, polyvinyl alcohol, anthracite and waste grease to uniformly mix the mixture, drying the mixture in vacuum till the water content of the mixture is 3-6wt% and granulating the mixture to obtain the biomass granular fuel.

Owner:广德县新杭镇聚源新型材料压膜厂

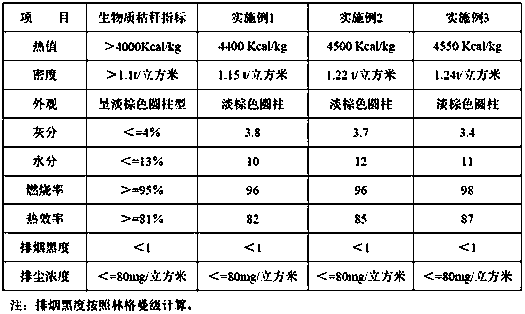

Biomass fuel and production process thereof

PendingCN107384501AImprove combustion effectImprove utilizationBiofuelsSolid fuelsProcess engineeringCombustion kinetics

The invention discloses biomass fuel and a production process thereof. The production process includes following steps: (1), selecting materials; (2), smashing; (3), drying; (4), extrusion forming. By studying heat release amount of the raw materials, factors having influence on burning rate and production process and analyzing burning dynamic characteristics of the formed biomass fuel, the fuel is simple in composition, reasonable in compatibility, low in cost, high in burning rate and low in slagging rate. The production process is safe, simple and convenient, burning performance of the biomass fuel can be improved effectively, running efficiency of a biomass boiler is improved, and utilization effect of the biomass fuel is promoted greatly.

Owner:唐山市华亿生物质燃料有限公司

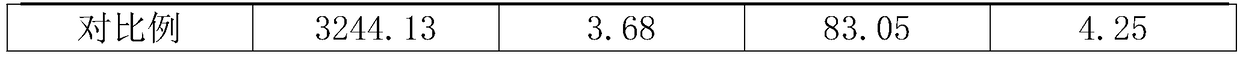

Method of reducing combustion clinkering rate of corn straw biomass particle fuel

InactiveCN108949285ASolve the problem of high slagging rateReduce slagging rateBiofuelsSolid fuelsPotassiumPorous ceramics

The invention relates to the technical field of modern agricultural industry and discloses a method of reducing the combustion clinkering rate of a corn straw biomass particle fuel. By means of combustion characteristic and combustion principle of dynamics, prepared porous ceramic particles with an adsorption function are doped into the corn straws, so that the condition that low-melting-point compounds are generated by alkaline metal elements such as potassium and sodium in biomass ash can be prevented, so that the clinkering rate is reduced and the melting point of ash of the corn straw particle fuel is improved, and the problem that the corn straws in the combustion process are easy to agglomerate and clinker is solved. By simulating a combustion test, the prepared corn straw biomass particle fuel is not coked fully at 1300 DEG C. The method solves the problem that the clinkering rate of the existing corn straw biomass particle combustion fuel is high is solved effectively, can achieve extreme utilization of resources and practical significance of environmental protection, has application value in development of biomass energy sources, and is a technical scheme which is worth being popularized and used extremely.

Owner:合肥市晶谷农业科技开发有限公司

Wood biomass fuel and production method thereof

InactiveCN109097139ATight textureHigh mechanical strengthBiofuelsSolid fuelsPulp and paper industryIndustrial engineering

The invention relates to the technical field of biomass fuel production, and more particularly relates to a wood biomass fuel and a production method thereof. The fuel comprises the following raw materials by mass fraction: 70-90% of forestry waste, 5-10% of a binder, 0.5-10% of a combustion promoter and 1-15% of an anti-slagging agent. According to the invention, the combustion efficiency, the mechanical strength and the slagging resistance of the wood biomass fuel are improved by introducing composite functional additives.

Owner:安徽聚焰生物科技股份有限公司

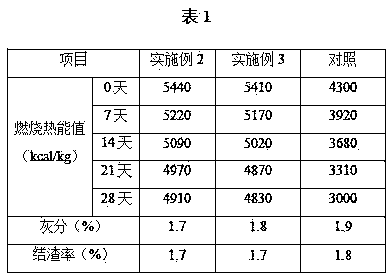

Biomass fuel with mildew-proof function

Biomass fuel with ha mildew-proof function is prepared from the following raw materials in parts by weight: 30 to 40 parts of leaves of camphor trees, 20 to 30 parts of tea stems, 25 to 35 parts of bamboo charcoal powder and 8 to 12 parts of attapulgite clay. The biomass fuel obtained by the invention has no bad peculiar smell during combustion, a heat value is up to about 5400kcal / kg, the ash content is smaller than 1.9 percent, a clinkering rate is smaller than 1.8 percent, and the storage time is long.

Owner:河南省国泰安信息技术有限公司

Composite waste fungus bag biomass fuel rod and preparation method thereof

InactiveCN110616100ATake advantage ofEasy to store and transportBiofuelsSolid fuelsCombustionAdhesive

The invention discloses a composite waste fungus bag biomass fuel rod. The composite waste fungus bag biomass fuel rod is formed by mixing 70%-79.8% of waste fungus bag crushed materials, 20%-29.8% ofpinecone peel and 0.2%-0.7% of adhesives. According to the biomass fuel rod disclosed by the invention, waste fungus bag crushed materials are used as main raw materials; polyvinyl alcohol is used asan adhesive, so that the biomass fuel rod is not easy to break in loading, unloading and transporting processes; the method has the advantages that the raw material source is wide, and the prepared biomass fuel rod is high in combustion rate, safe to use, capable of being continuously used, low in bottom slag ash deposition rate, small in combustion pollution, small in solid discharge amount andthe like. The invention further discloses a preparation method of the composite waste fungus bag biomass fuel rod.

Owner:YANBIAN CHANGBAISHAN PHARMA CO LTD

Rice husk-straw biomass particle

InactiveCN108611152ATake advantage ofWide variety of sourcesBiofuelsSolid fuelsBottom ashSurface layer

The invention discloses a rice husk-straw biomass particle. The rice husk-straw biomass particle comprises a composite core layer, a rice husk layer, a straw layer, through holes, a connecting bulge,connecting pins, a connecting groove and connecting insertion holes, wherein the straw layer serves as the surface layer of the biomass particle; the rice husk layer is arranged inside the straw layer; the composite core layer is arranged inside the rice husk layer; the connecting bulge and the connecting groove are formed in the two ends of the biomass particle respectively; the connecting pins are arranged on the connecting bulge; the connecting insertion holes are formed in the connecting groove; the through holes are formed in the surface of the biomass. Crop straw and rice husk are used as main components, a proper amount of cleaning additive is added, and a multi-layer structure is obtained by compounding, so that the rice husk-straw biomass particle is clean and environment-friendly, energy is fully utilized, and waste biomass fuel is fully utilized; the rice husk-straw biomass particle is wide in raw material sources, high in combustion rate, safe to use, sustainable to use, low in bottom ash slagging rate, low in combustion pollution, recyclable in waste residues.

Owner:安徽东升精密铸钢件有限公司

Method for improving combustion thermal efficiency of straw biomass carbon

ActiveCN110331021ASolve the problem of easy caking and slaggingImprove combustion thermal efficiencyBiofuelsSolid fuelsOxygenCombustion kinetics

The invention relates to the technical field of modern agricultural industry, and discloses a method for improving the combustion thermal efficiency of straw biomass carbon. Through researches on thecombustion characteristics and the laws of combustion dynamics principles, in the production process of a biomass carbon fuel, a prepared sintering aid is mixed into pretreated biomass straw, mixed evenly in a high-speed mixer, pressed into blocks, placed in a high-temperature resistant mica plate container, sent into a muffle furnace for heating, and carbonized to obtain the fuel, and the structural characteristic can accelerate the circulation of oxygen, improves the heat transfer efficiency, allows the ambient temperature around the biomass carbon to rise rapidly, ensures continuous, stableand high-speed combustion operation, improves the combustion thermal efficiency, prevents alkali metal elements in ash from generating compounds with low melting points, reduces the slagging rate, increases the slagging temperature of the straw biomass carbon fuel, solves the problem of easy agglomeration and slagging in the combustion process of the straw biomass carbon, and significantly reduces the emission of harmful gases in the combustion process.

Owner:宿州青果知识产权服务有限公司

Environment-friendly and inflammable fuel rod and manufacturing process thereof

InactiveCN105950250ARaise the ash melting pointEfficient removalBiofuelsSolid fuelsFiberVegetable oil

The invention discloses an environment-friendly and inflammable fuel rod and a manufacturing process thereof. According to a formula, the environment-friendly and inflammable fuel rod is prepared from, in percentage by weight, 20%-40% of elm sawdust, 10%-30% of elm bark, 5%-12% of waste carbon powder, 2%-6% of an alkaline paper pulp waste liquid, 15%-40% of dewatered sludge, 3%-10% of waste paper pulp, 2%-6% of vegetable oil sediments and 4%-12% of furnace slag. Compared with the prior art, the environment-friendly and inflammable fuel rod and the manufacturing method have the advantages as follows: substance structures in the elm bark can be effectively improved, carbon elements are kept, fiber structures of the fuel rod can be softened, and the fuel rod can be easily processed and formed; the main raw materials are elm sawdust and bark, the sulfur content is lower than 0.1%, the content of ash is lower and ranges from 1.6%-3.2%, burning is easy, the burning time is long, the fuel rod is environment-friendly, and the operation cost is reduced by about 40% while compared with that by adopting conventional fuel.

Owner:安徽省珍云生物能源有限公司

Biomass granular fuel and preparation method thereof

The invention provides biomass granular fuel and a preparation method thereof. The biomass granular fuel comprises 0.1-0.5% of adhesive, 15-25% of sawdust, 65-75% of straw, 5-15% of peanut shell and 0.1-0.5% of additives. The biomass granular fuel has the advantages that the straw is used as the main component and accounts for more than 65% of the biomass granular fuel; polyvinyl alcohol is used as the adhesive and is combined with a plant starch adhesive or a lignin adhesive to guarantee that biomass granules do not rupture during transportation, and the combustible polyvinyl alcohol can be used as a combustion improver like KMNO4 to increase the combustion rate of the biomass granules; calcium sulfate is used as the potassium removing agent to reduce the KCl formation, which causes combustion unevenness, during combustion; the prepared biomass granular fuel is wide in raw material source, high in combustion rate, safe to use, capable of being used continuously, low in bottom ash clinkering rate and low in combustion pollution.

Owner:菏泽市鼎成生物质燃料有限公司

Green environment-friendly biomass pellet fuel

The invention specifically relates to a green environment-friendly biomass pellet fuel, belonging to the technical field of biomass fuels. The green environment-friendly biomass pellet fuel comprisesthe following raw materials by weight: 55 to 60 parts of corn straws, 33 to 50 parts of dead branches, 35 to 40 parts of water grass, 1.2 to 2.5 parts of a combustion improver, 35 to 45 parts of wheatstraws, 25 to 35 parts of rice husks, 0.33 to 0.65 part of a leveling agent, 15 to 20 parts of wheat bran, 8 to 13 parts of food waste and 5 to 15 parts of sawdust. The green environment-friendly biomass pellet fuel of the invention has the following beneficial effects: the raw materials of biomass pellets are easily available; all the raw materials are organic substances, and a product obtainedafter combustion is environmentally friendly; waste utilization is realized, and damage to environment is reduced; the combustion improver is added to make the biomass pellets burn more sufficiently,so ash is reduced; the leveling agent is used, so gaps between fibrous tissue in the biomass pellet raw materials are increased, calorific value is improved, and the generation of ash is reduced.

Owner:池州众丰现代农业发展有限公司

Biomass fuel

Disclosed is biomass fuel. The biomass fuel is prepared from, by weight, 80-90 parts of ramie bone, 10-15 parts of attapulgite clay powder and 0.5-1 part of calcium phosphate. The burning heat energyof the obtained biomass fuel reaches up to about 6,000 kcal / kg, the ash content is smaller than 1.3%, the slag bonding rate is smaller than 2%, and the storage period is long.

Owner:河南省国泰安信息技术有限公司

High-combustion-value fuel rod and manufacturing process thereof

The invention discloses a high-combustion-value fuel rod and a manufacturing process thereof. A formula of the high-combustion-value fuel rod adopts the following weight percentage: 20 to 40% of paulownia saw dust, 10 to 30% of paulownia bark, 5 to 12% of waster carbon powder, 2 to 6% of acidic pulp mill waste liquor, 15 to 40% of food sludge, 3 to 10% of waste paper pulp, 2 to 6% of glass cement and 4 to 12% of calcium oxide. Compared with the prior art, the high-combustion-value fuel rod and the manufacturing process thereof, which are disclosed by the invention, have the following advantages that: in the invention, by performing a reaction on the paulownia bark and the acidic pulp mill waste liquor under a certain conditions, the material structure in the paulownia bark is improved, combustible components in the high-combustion-value fuel rod are kept, and active components in the high-combustion-value fuel rodare increased, so that the fuel rod can be sufficiently burnt; macromolecular substances in the high-combustion-value fuel rod are degraded into low molecular weight organic matter, so that not only is a raw material easy to form, but also an adhesion degree of the fuel rod can be reinforced, and residues and offcut in the machining process are reduced; combustion heat of the fuel rod reaches about 4,600 Kcal / kg; the fuel rod can be used for equipment or processes with high requirements for heat.

Owner:安徽省珍云生物能源有限公司

Biomass particles with high combustion rate

PendingCN109321305AHigh calorific valueImprove molding rateBiofuelsSolid fuelsEnvironmental resistanceParaffin wax

The invention relates to the technical field of biomass fuel and in particular relates to biomass particles with a high combustion rate. The biomass particles are prepared from the following raw materials in parts by weight: 25 to 40 parts of corn straw, 35 to 45 parts of soybean straw, 12 to 20 parts of rice husk, 9 to 15 parts of poultry excrement, 10 to 15 parts of radix bupleuri medicine residue, 10 to 16 parts of radix isatidis medicine residue, 0.12 to 0.16 part of ammonium perchlorate and 2 to 7 parts of paraffin wax. According to the biomass particles provided by the invention, the rawmaterials composed of the corn straw, the soybean straw, the rice husk, the poultry excrement, the radix bupleuri medicine residue and the radix isatidis medicine residue are adopted, so that the rawmaterials of the biomass particles have a wide source and are easy to obtain; in a combustion process, substances including sulfide and the like, which have hazards on the environment, are not generated; the recycling of wastes is solved, environment protection and energy saving are facilitated, and the clinkering rate after combustion is low; the ammonium perchlorate is added; the ammonium perchlorate has good combustion performance and high heat capacity and heat energy can be sufficiently released in a combustion process of the biomass particles, so that the calorific value of the biomassparticles is improved and the clinkering rate of a combustion product is reduced.

Owner:池州众丰现代农业发展有限公司

Moisture-proof and mildew-proof biomass pellet fuel and preparation method thereof

ActiveCN110903874BMoisture-proof and mildew-proofGuaranteed stabilityBiofuelsSolid fuelsPtru catalystBamboo charcoal

The invention belongs to the field of biological energy. A moisture-proof and mildew-proof biomass pellet fuel, comprising the following components calculated by weight percentage: 8-10 parts of camphor wood chips, 12-18 parts of modified straw, 10-15 parts of modified bamboo charcoal, 0.1-0.5 parts of antibacterial agent, Catalyst 0.1-0.5 parts. The invention has good anti-mildew and moisture-proof ability, high thermal efficiency and high combustion calorific value.

Owner:惠州景峰环保新能源有限公司

Method for reducing clinkering rate of straw biomass particle fuel

InactiveCN108913265AReduce slagging rateReduce alkali metal contentBio-organic fraction processingBiofuelsMetaboliteCentrifugation

The invention mainly relates to the technical field of biomass particle fuel processing, and discloses a method for reducing the clinkering rate of straw biomass particle fuel. The method comprises the following steps: carrying out crushing, carrying out fermenting, carrying out washing, carrying out water treatment and carrying out granulation. According to the provided method for reducing the clinkering rate of the straw biomass particle fuel, the method is simple, no harmful metabolites are generated, the method is green and environmentally friendly, the content of alkali metals in straw can be effectively reduced, the combination of the particle fuel is firm, the clinkering rate is obviously reduced to 7.3%, and the combustion condition of the particle fuel is obviously improved. The crushed straw particles are small, and then water is added for soaking, so that the alkali metals in the straw particles is diffused into the water with a low concentration, and the alkali metal content of the straw particles is reduced after centrifugation.

Owner:合肥市晶谷农业科技开发有限公司

Biomass fuel

ActiveCN113430027AIncrease cavity densityIncrease the difficultyBiofuelsSolid fuelsFlue gasProcess engineering

The invention discloses a biomass fuel which is prepared by the following method: crushing and drying crop straw residues to obtain residue powder; and mixing the residue powder, an anti-slagging agent and a functional additive, and then pressing and cutting the mixture to obtain the biomass fuel. The biomass fuel disclosed by the invention can be fully combusted, and is high in calorific value and low in flue gas slagging rate.

Owner:唐山市华亿生物质燃料有限公司

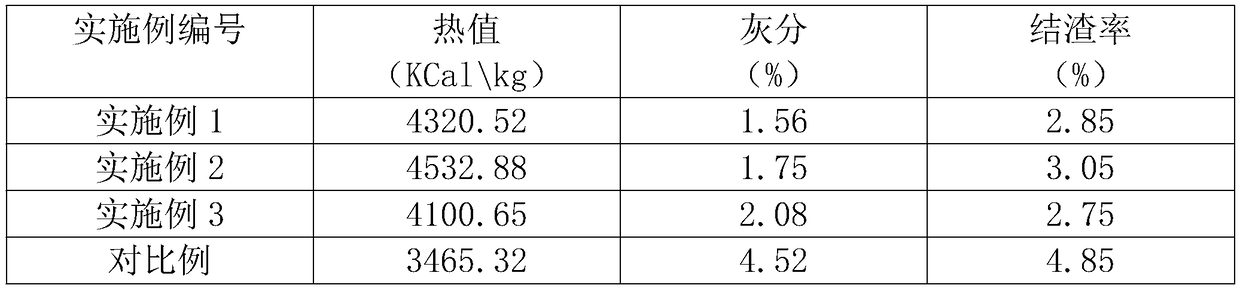

High-calorific-value low-slagging biomass granular fuel and preparation method thereof

ActiveCN112080326AGood molding effectHigh mechanical strengthBiofuelsSolid fuelsMaterials scienceBacterial cellulose

The invention discloses a preparation method of a high-calorific-value low-slagging biomass granular fuel. The method comprises the following steps: mixing straw powder with a mixed suspension prepared from calcium carbonate and bacterial cellulose, performing drying, carrying out steam explosion treatment to obtain steam explosion modified straw powder, and uniformly mixing the steam explosion modified straw powder with n-octyl alcohol according to a certain ratio; carrying out high-temperature stirring reaction under a negative pressure condition to obtain a straw-based composite material; and finally, carrying out molding processing on the straw-based composite material to obtain the high-calorific-value low-slagging biomass granular fuel. The biomass granular fuel disclosed by the invention is high in heat value, low in slagging rate, good in forming effect, not easy to break and excellent in quality.

Owner:怀宁县泰华新能源科技有限公司

Biomass fuel and production process thereof

The invention discloses a biomass fuel and a production process thereof. The production process comprises the following steps: crushing and drying crop straw residues to obtain residue powder, then mixing the residue powder with an anti-slagging agent, and then pressing and cutting to obtain granular biomass fuel. A preparation method of the anti-slagging agent comprises the following steps: carrying out ball milling on ore to obtain ore powder; cleaning the ore powder, and then standing, centrifuging, filtering, drying and crushing; mixing the ore powder, a foaming agent and a wetting agent, and stirring to obtain a to-be-sintered blank; and sintering, cooling to room temperature, and crushing to obtain the anti-slagging agent. The biomass fuel obtained by the specific process has the advantages of high calorific value and low slagging rate.

Owner:贵州省霖生木业有限公司

Jerusalem artichoke straw fuel rod and preparation method thereof

The invention discloses a jerusalem artichoke straw fuel bar and a preparing method thereof. The jerusalem artichoke straw fuel bar is prepared from, by weight, 50-80 parts of jerusalem artichoke straw, 15-30 parts of craw coal, 1-3 parts of calcium oxide, 2-4 parts of kieselguhr, 0.5-1 part of combustion improver, 1-3 parts of sulfur-fixing agent and 0.5-1.5 parts of bentonite. The characteristic of high burning caloric value of jerusalem artichoke straw is fully utilized, the combustion supporting component is added to the fuel bar, additives including calcium oxide and kieselguhr are added, the clinkering rate and corrosiveness of jerusalem artichoke straw are reduced, the prepared jerusalem artichoke straw fuel bar can be widely applied to industrial and civilian production, the utilization rate of jerusalem artichoke straw is increased, and extension and development of the jerusalem artichoke industrial chain are promoted.

Owner:山东益得来生物科技有限公司

Production process of pure cypress biomass pellet fuel

The invention relates to a production technique of a pure cedar biomass granular fuel, which comprises the following steps: screening cedar sawdust, mixing materials, drying, cooling, carrying out secondary mixing on the mixture and cedar shavings, and granulating to obtain the finished product. The technique provided by the invention has the advantages of simpleness, less generated dust, high forming ratio and high yield; and the prepared biomass granular fuel has the advantages of high heating value, low slagging tendency, wide raw material resources and low production cost.

Owner:蓬溪县天桥木业有限公司

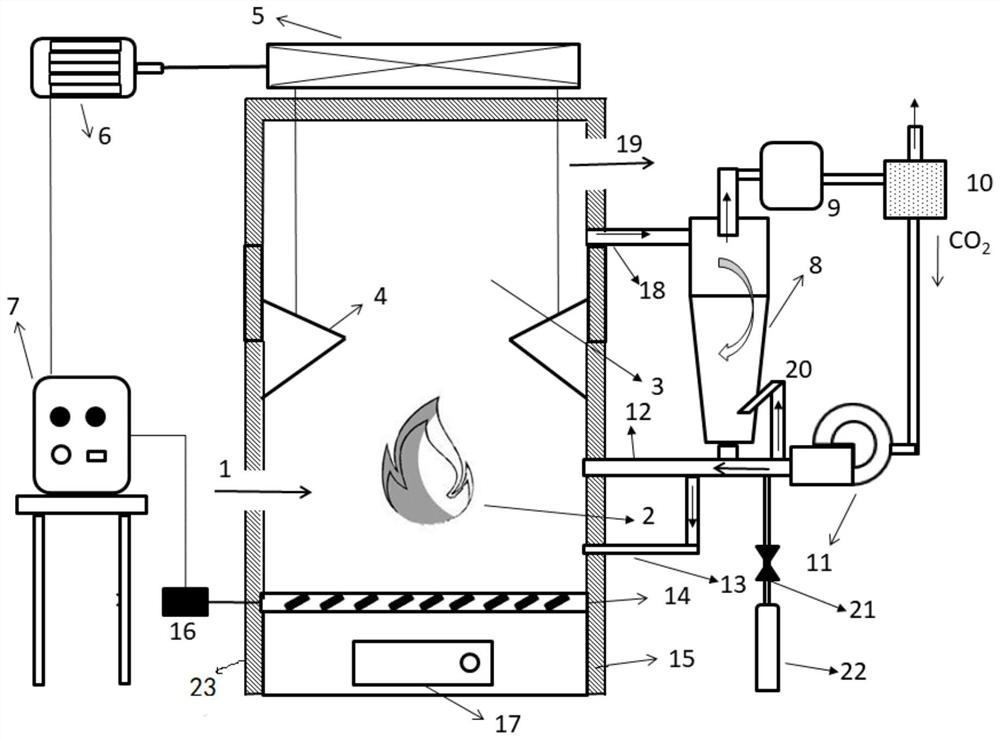

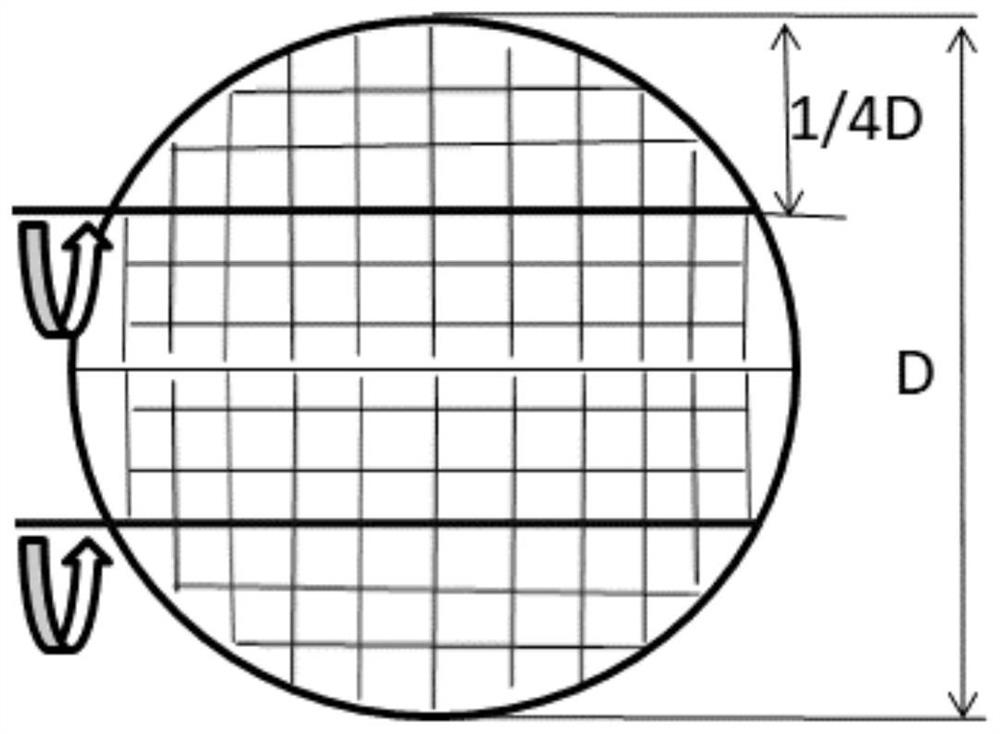

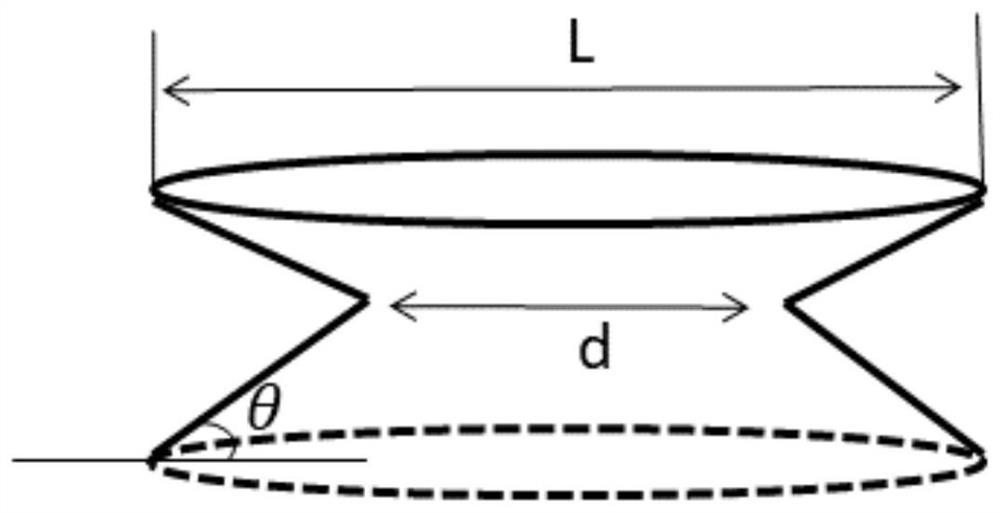

Burner capable of adjusting position of girdling type structure

PendingCN112815300AShorten speedBurn fullySolid fuel combustionBlast-producing apparatusThermodynamicsCombustion chamber

The invention provides a burner capable of adjusting the position of a girdling type structure. The burner comprises a machine body, the machine body is internally provided with the girdling type structure capable of moving up and down, the inside of the machine body is divided into an upper burning chamber and a lower burning chamber by the girdling type structure, the machine body is provided with a fuel inlet in the lower burning chamber, the upper burning chamber of the machine body is provided with a first burner outlet, the upper burning chamber of the machine body is provided with a second burner outlet, the second burner outlet is connected with a cyclone separator, the cyclone separator is connected with a flue gas pretreatment device, the flue gas pretreatment device is connected with a CO2 separation device, the CO2 separation device is connected with a fan, and the fan communicates with the lower burning chamber through an upper secondary air pipe and a lower secondary air pipe. The burning effect of the burner during burning can be adjusted; in addition, the content of fly ash and pollutants at the fire outlet of the burner can be reduced, and the purpose of clean burning is achieved.

Owner:SHANDONG UNIV OF TECH

A kind of anti-slagging biomass solid particle fuel

The invention discloses an anti-slagging biomass solid granular fuel and solves a problem that a biomass solid granular fuel in the prior art is liable to slag and is low in combustion efficiency. The anti-slagging biomass solid granular fuel is prepared from following raw materials, by weight, 60-70 parts of crop straws, 10-15 parts of wood chips, 5-10 parts of bagasse, 3-5 parts of a combustion-promoting agent and 1-3 parts of an anti-slagging agent. The anti-slagging biomass solid granular fuel is simple in components, reasonable in formula, low in cost, high in combustion efficiency and low in slagging rate.

Owner:江山华隆能源开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com