Biomass granular fuel and preparation method thereof

A biomass particle and fuel technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of low utilization rate of biomass particle fuel, easy to break, unstable production process, etc., and achieve simple and stable production process, bonded The effect of good degree and easy control operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

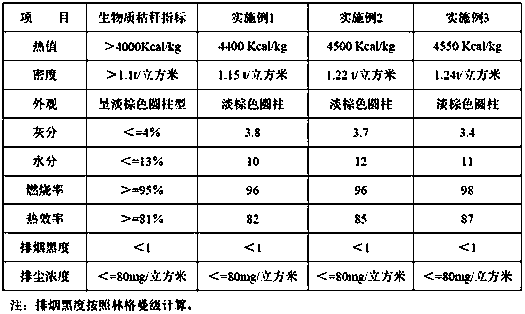

Examples

Embodiment 1

[0021] A kind of biomass granular fuel is made up of following raw materials in parts by mass:

[0022] Adhesive 0.1%, saw foam 25%, straw 65%, peanut shell 9.8%, additive 0.1%;

[0023] Described tackiness agent is the mixture of the starch glue of mass ratio 6:1 or lignin glue and polyvinyl alcohol;

[0024] The additive is KMnO with a mass ratio of 1:1 4 Mixture with calcium sulfate.

[0025] A kind of preparation method of above-mentioned biomass particle fuel:

[0026] (1) Use a pulverizer to further pulverize the raw materials into powders below 0.5mm, add adhesives and additives, and mix them evenly with a mixer to control the moisture content to 10%;

[0027] (2) The material in step (1) is softened by steam, sent to the granulator for extrusion granulation, and pressed into granules with a diameter of 3mm and a length of 12mm, and the moisture content is controlled at 10%;

[0028] (3) Transport the biomass pellet fuel to the cooler for cooling, screening and pack...

Embodiment 2

[0030] A kind of biomass granular fuel is made up of following raw materials in parts by mass:

[0031] Adhesive 0.5%, saw foam 19%, straw 75%, peanut shell 5%, additive 0.5%;

[0032] Described tackiness agent is the mixture of the starch glue of mass ratio 3:1 or lignin glue and polyvinyl alcohol;

[0033] The additive is KMnO with a mass ratio of 1: 4 4 Mixture with calcium sulfate.

[0034] A kind of preparation method of above-mentioned biomass particle fuel:

[0035] (1) Use a pulverizer to further pulverize the raw materials into powders below 0.5mm, add adhesives and additives, and mix evenly with a mixer to control the moisture content to 15%;

[0036] (2) The material in step (1) is softened by steam, sent to the granulator for extrusion granulation, and pressed into granules with a diameter of 6mm and a length of 24mm, and the moisture content is controlled at 15%;

[0037] (3) Transport the biomass pellet fuel to the cooler for cooling, screening and packaging....

Embodiment 3

[0039] A biomass pellet fuel, which is composed of the following raw materials in parts by mass: 0.3% of adhesive, 20% of sawdust, 69.5% of straw, 10% of peanut shell, and 0.2% of additive;

[0040] Described tackiness agent is the mixture of the starch glue of mass ratio 4:1 or lignin glue and polyvinyl alcohol;

[0041] The additive is KMnO with a mass ratio of 1: 2 4 Mixture with calcium sulfate.

[0042] A kind of preparation method of above-mentioned biomass particle fuel:

[0043] (1) Use a pulverizer to further pulverize the raw materials into powders below 0.5mm, add adhesives and additives, mix them evenly with a mixer, and control the moisture content to 12%;

[0044] (2) The material in step (1) is softened by steam, sent to the granulator for extrusion granulation, and pressed into granules with a diameter of 5mm and a length of 20mm, and the moisture content is controlled at 11%;

[0045] (3) Transport the biomass pellet fuel to the cooler for cooling, screenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com