Method for reducing clinkering rate of straw biomass particle fuel

A technology of biomass particles and slagging rate, applied in the direction of biofuel, waste fuel, fertilizer made of biological waste, etc., can solve the problem of small anti-slagging effect, etc., and achieve the effect of improving melting point, rich nutrition and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

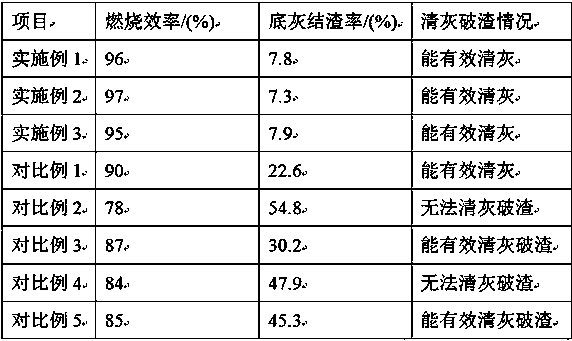

Examples

Embodiment 1

[0018] A method for reducing the slagging rate of straw-based biomass pellet fuels, comprising the following steps:

[0019] (1) Crushing: crush the straw to 80 mesh, add water, completely submerge the straw, soak at a constant temperature of 40°C for 2 days, filter to obtain soaking material and soaking water;

[0020] (2) Fermentation: add water to the soaking material again, add fermenting bacteria, ferment at 26°C for 4 days, filter to obtain fermenting material and fermented water; 3% by weight, consisting of the following strains by weight: Bacillus natto 15, Iron bacteria 11, Saccharomyces cerevisiae 8, Lactobacillus plantarum 4;

[0021] (3) Washing: Add water to the fermented material, ultrasonically wash at 50°C and 32kHz for 20 minutes, repeat washing with water twice, and filter to obtain the washing material and washing water;

[0022] (4) Water treatment: mix the soaking water, fermented water and washing water evenly, freeze and concentrate until the volume is ...

Embodiment 2

[0027] A method for reducing the slagging rate of straw-based biomass pellet fuels, comprising the following steps:

[0028] (1) Crush: crush the straw to 80 mesh, add water, completely submerge the straw, soak at a constant temperature of 43°C for 3 days, filter to obtain soaking material and soaking water;

[0029] (2) Fermentation: add water to the soaking material again, insert the fermenting bacteria, ferment at a constant temperature of 27°C for 5 days, filter to obtain the fermenting material and fermented water; 3% by weight, consisting of the following strains by weight: Bacillus natto 16, Iron bacteria 12, Saccharomyces cerevisiae 9, Lactobacillus plantarum 5;

[0030] (3) Washing: Add water to the fermented material, ultrasonically wash at 53°C and 33kHz for 25 minutes, repeat adding water for 3 times, and filter to obtain the washing material and washing water;

[0031] (4) Water treatment: mix the soaking water, fermented water and washing water evenly, freeze an...

Embodiment 3

[0036] A method for reducing the slagging rate of straw-based biomass pellet fuels, comprising the following steps:

[0037] (1) Crush: crush the straw to 100 mesh, add water, completely submerge the straw, soak at a constant temperature of 45°C for 3 days, and filter to obtain soaking material and soaking water;

[0038] (2) Fermentation: add water to the soaking material again, add fermenting bacteria, ferment at 28°C for 5 days, filter to obtain fermenting material and fermented water; 4% by weight, consisting of the following strains by weight: Bacillus natto 17, Iron bacteria 13, Saccharomyces cerevisiae 10, Lactobacillus plantarum 6;

[0039] (3) Washing: add water to the fermented material, ultrasonically wash at 55°C and 34kHz for 30 minutes, repeat adding water for 3 times, and filter to obtain the washing material and washing water;

[0040] (4) Water treatment: mix the soaking water, fermented water and washing water evenly, freeze and concentrate until the volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com