Jerusalem artichoke straw fuel rod and preparation method thereof

A technology of Jerusalem artichoke straw and its production method, which is applied in the direction of fuel, waste fuel, biofuel, etc., can solve the problems of low utilization rate of straw resources, environmental pollution, waste of resources, etc., reduce slagging rate and corrosiveness, promote extension and The effect of development and improvement of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Collection of raw materials: After the tubers of Jerusalem artichoke in the field are mature, and the aboveground leaves and stems of Jerusalem artichoke are withered and yellow, use a straw harvester to harvest the stems of Jerusalem artichoke;

[0023] (2) Drying and impurity removal: dry the harvested Jerusalem artichoke stalks in the air, control the moisture content of the stalks below 15%, and pass the stalks through a vibrating sieve to remove impurities such as dust mixed on the stalks;

[0024] (3) Raw material pulverization: the Jerusalem artichoke stalk that removes dust and impurity is pulverized into 20 purpose scraps with pulverizer, standby;

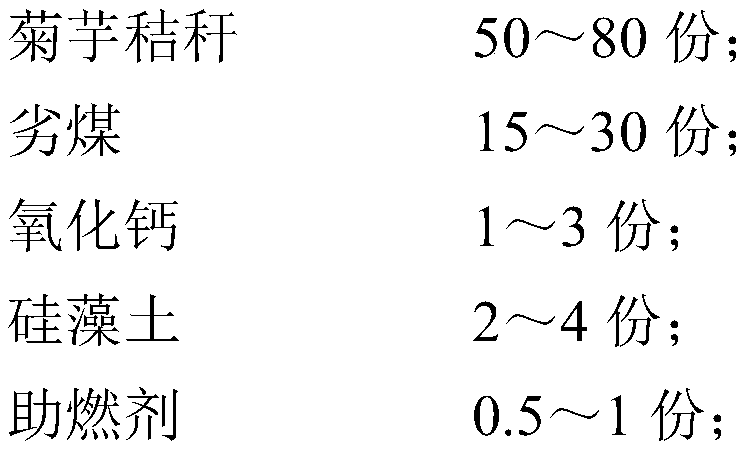

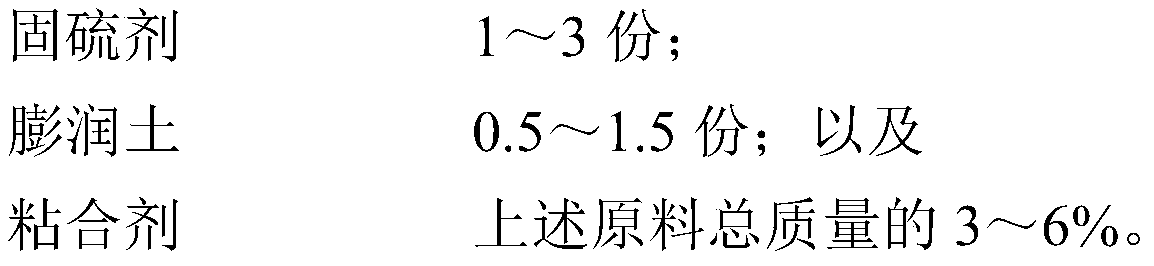

[0025] (4) Mixing: In parts by weight, mix 70 parts of Jerusalem artichoke straw scraps, 20 parts of bad coal, 3 parts of calcium oxide, 4 parts of diatomaceous earth, 1 part of combustion aid, 1 part of sulfur-fixing agent, and 1 part of bentonite uniform; wherein, the combustion aid is a mixture of potassium n...

Embodiment 2

[0031] (1) Collection of raw materials: After the tubers of Jerusalem artichoke in the field are mature, and the aboveground leaves and stems of Jerusalem artichoke are withered and yellow, use a straw harvester to harvest the stems of Jerusalem artichoke;

[0032] (2) Drying and impurity removal: dry the harvested Jerusalem artichoke stalks in the air, control the moisture content of the stalks below 13%, and pass the stalks through a vibrating sieve to remove impurities such as dust mixed on the stalks;

[0033] (3) Raw material pulverization: the Jerusalem artichoke stalk that removes dust and impurity is pulverized into 30 purpose scraps with pulverizer, standby;

[0034] (4) Mixing: In parts by weight, mix 79 parts of Jerusalem artichoke straw scraps, 15 parts of bad coal, 2 parts of calcium oxide, 2 parts of diatomite, 0.5 parts of combustion enhancer, 1 part of sulfur-fixing agent, and 0.5 parts of bentonite uniform; wherein, the combustion aid is a mixture of potassium...

Embodiment 3

[0040] (1) Collection of raw materials: After the tubers of Jerusalem artichoke in the field are mature, and the aboveground leaves and stems of Jerusalem artichoke are withered and yellow, use a straw harvester to harvest the stems of Jerusalem artichoke;

[0041] (2) Drying and impurity removal: dry the harvested Jerusalem artichoke stalks in the air, control the water content of the stalks below 14%, and pass the stalks through a vibrating screen to remove impurities such as dust mixed on the stalks;

[0042] (3) Raw material pulverization: the Jerusalem artichoke stalk that removes dust and impurity is pulverized into 30 purpose scraps with pulverizer, standby;

[0043] (4) Mixing: In parts by weight, mix 60 parts of Jerusalem artichoke straw scraps, 30 parts of bad coal, 2.5 parts of calcium oxide, 4 parts of diatomaceous earth, 1 part of combustion aid, 2 parts of sulfur-fixing agent, and 0.5 parts of bentonite uniform; wherein, the combustion aid is a mixture of potassi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com