Burner capable of adjusting position of girdling type structure

A burner, adjustable technology, applied in the direction of solid fuel combustion, burner, combustion method, etc., can solve the problems of short residence time in the furnace, insufficient combustion, low combustion efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

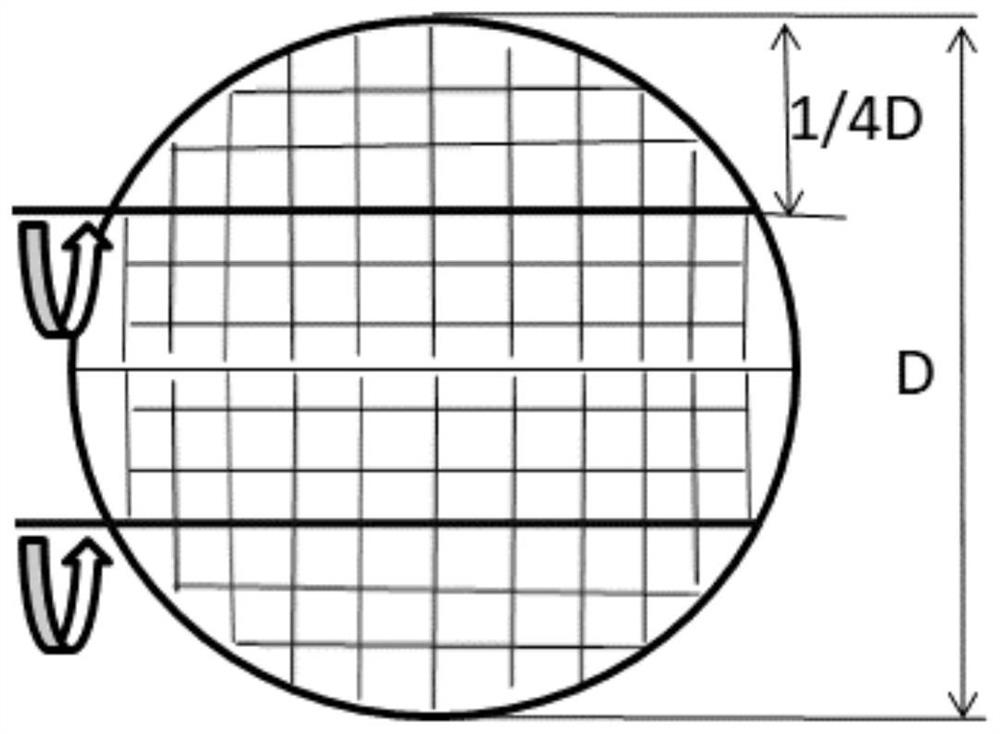

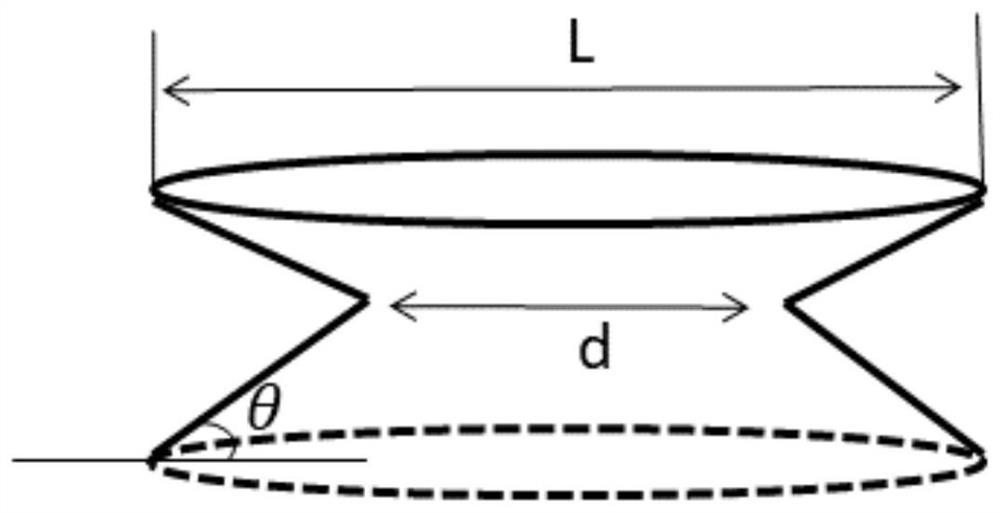

[0075] A company needs to use a burner to burn different types of biomass, and NO in the flue gas at the outlet of the burner x Content and fly ash content need to be strictly controlled to meet national requirements. Because the amount of fly ash produced when different types of biomass are burned is different from the degree of adequacy of burning, so the height of the waist-shaped structure needs to be adjusted when each type of biomass is burned. In this way, the biomass can be fully burned, the burning residence time is prolonged, and the amount of fly ash produced during burning is the smallest.

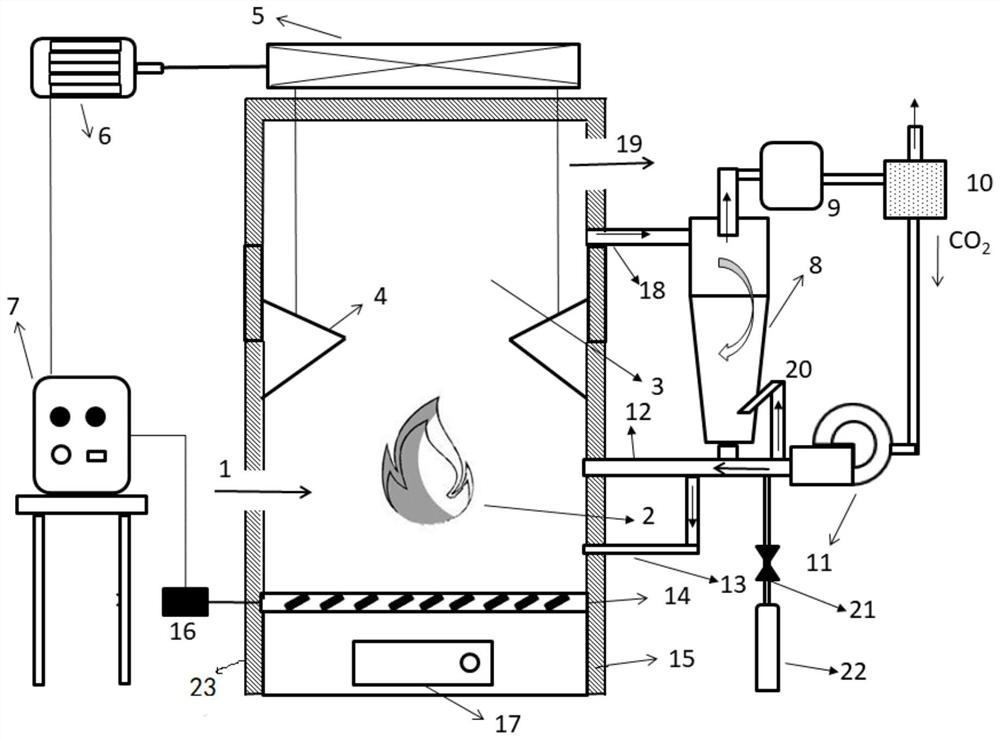

[0076] When using the burner of the present invention for fuel combustion, the biomass enters the lower combustion chamber 2 from the fuel inlet, ignites and starts to burn after mixing with air, and the special waist structure 4 can effectively block most of the unburned fly ash to reduce the fly ash content at the outlet of the burner; at the same time, the cyclone separator...

Embodiment 2

[0078] An enterprise is close to farmland and mainly uses straw biomass as fuel. Due to the characteristics of high alkali metal content and high volatile content of straw biomass, problems such as grate, ash on the heated area and slagging are prone to occur during combustion. Therefore, when burning fuel, it is necessary to consider not only the pollution to the environment, but also the problem of easy slagging of straw biomass burning. A large number of studies have proved that when biomass is burned, appropriately reducing the combustion temperature in the burner can effectively reduce the slagging rate, and the combustion temperature of the burner can be controlled by controlling the air distribution.

[0079] When using the burner of the present invention for fuel combustion, straw-like biomass fuel enters the lower combustion chamber 2 from the fuel inlet 1, and starts to ignite and burn after mixing with air. The burner is designed with an upper secondary air duct 12...

Embodiment 3

[0081] A company is using a garbage incinerator to burn different types of garbage with different moisture content every day. Because of the wide variety of garbage, high moisture content, and poor combustion characteristics, a large amount of smoke of harmful substances will be produced during combustion. At the same time, the unburned fly ash and polluted gases at the outlet of the burner have high content, which will cause great harm to the environment.

[0082] When using the burner of the present invention to burn waste fuel, the problems of poor ignition characteristics, unstable combustion, or too low combustion temperature can be effectively improved by regulating the secondary air of the burner. The specific method is: open the oxygen tank valve 21, control the oxygen intake, and along with the increase of the oxygen concentration, the oxygen and CO 2 The CO separated in the separation device 10 2 It is mixed at the outlet of the fan 11 and blown into the interior of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com