Production process of pure cypress biomass pellet fuel

A technology of pellet fuel and production process, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of many production process steps, complex raw material composition, wear and tear of production equipment, etc., to reduce the use of process equipment, reduce process steps, Production cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

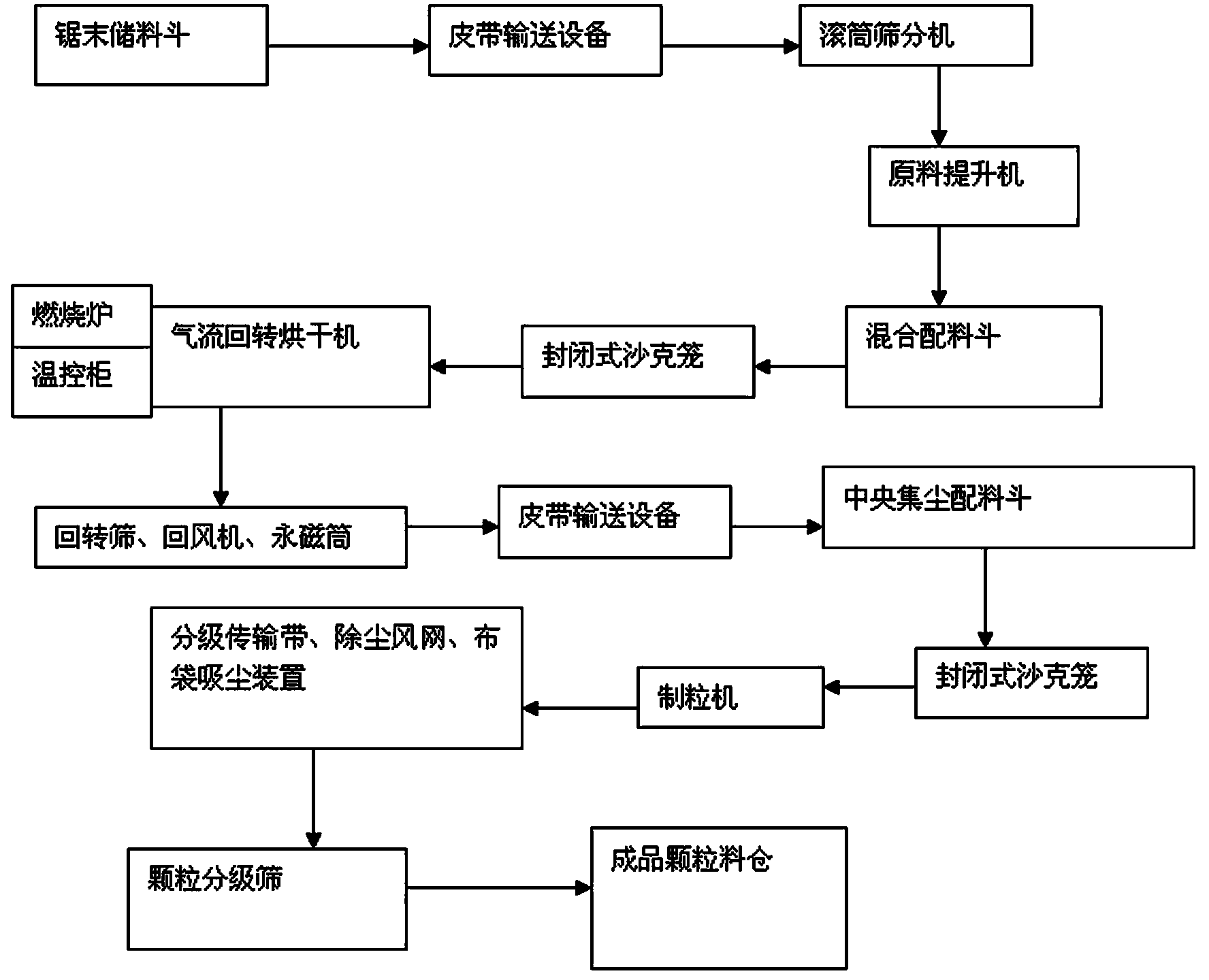

[0041] The production process of the present embodiment is as follows:

[0042] Step 1. Sieve the cypress sawdust with a water content of 40% through a drum screening machine to remove bulk materials to obtain qualified cypress sawdust with a particle size of ≤3mm;

[0043] Step 2, send the qualified cypress sawdust into the mixing hopper through the raw material hoist, mix according to the ratio of cypress sawdust: cypress shavings=2.5:1, the cypress shavings have a water content of 10%, a diameter of 15mm, and a thickness of 1.5mm;

[0044] Step 3. Send the mixed material obtained after mixing into a rotary dryer for one-time drying. The air supply temperature of the combustion furnace of the rotary dryer is 130° C., and the moisture content of the dried material is 12%;

[0045] Step 4. The dried mixed material is sent to the return fan through the rotary sieve for ventilation and cooling, and the temperature is lowered to 40°C. At the same time, the metal particles in the ...

Embodiment 2

[0051] Step 1, sieve the cypress sawdust with a water content of 45% through a drum screening machine to remove bulk materials to obtain qualified cypress sawdust with a particle size of ≤3mm;

[0052] Step 2. Send the qualified cypress sawdust into the mixing hopper through the raw material hoist, and mix according to the ratio of cypress sawdust: cypress shavings = 2.5:1. The cypress shavings have a water content of 12%, a diameter of 14mm, and a thickness of 1.5mm. ;

[0053] Step 3. Send the mixed material obtained after mixing into a rotary dryer for one-time drying. The air supply temperature of the combustion furnace of the rotary dryer is 125° C., and the moisture content of the dried material is 10%;

[0054] Step 4. The dried mixed material is sent to the return fan through the rotary sieve for ventilation and cooling, and the temperature is lowered to 40°C. At the same time, the metal particles in the mixed material are absorbed by the permanent magnet cylinder;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com