Automatic high-efficient biomass granular fuel combustor

A technology of biomass pellets and burners, a kind of combustion equipment applied to boilers, in the field of automatic high-efficiency biomass pellet fuel burners, can solve the problems of thermal performance of combustion equipment, endangering the safety of combustion equipment, scaling and other problems, and achieve Novel structure, prevent slagging and improve combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

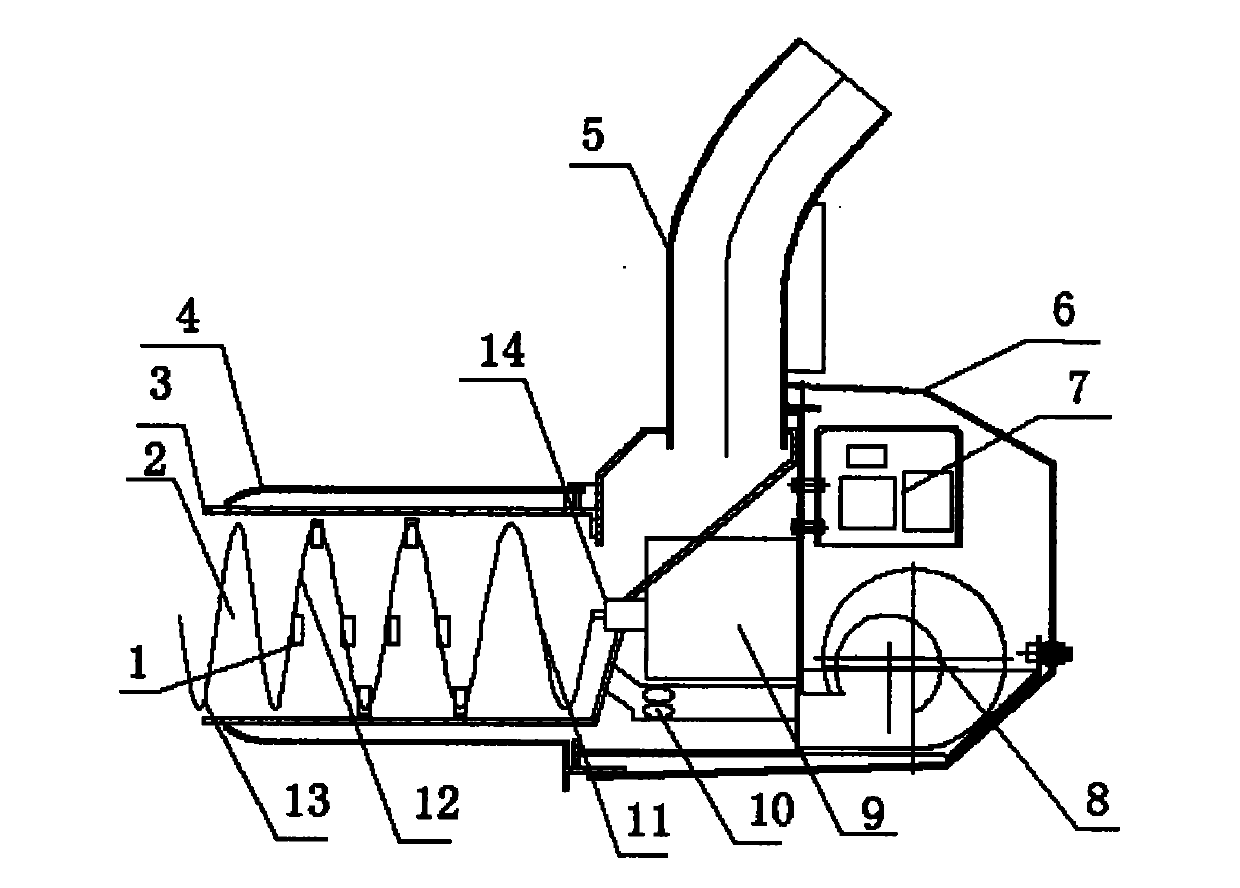

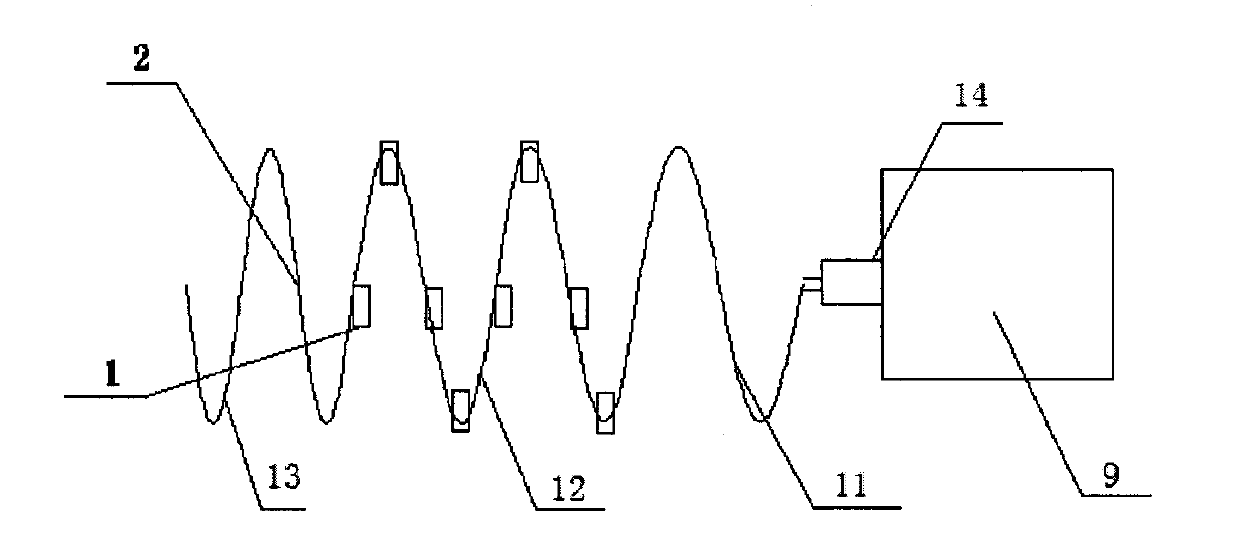

[0046] Example 1: Automatic high-efficiency biomass pellet fuel burner for the worst slagging

[0047] For raw materials such as corn stalks and Korean pine that contain relatively high Si elements and other alkali metal elements, the Si content is basically 25%, and the K element content is 10% to 15%. After combustion, the slagging is the most serious and the ash content is the most. The slag-breaking and dust-cleaning mechanism with an angle between the side of the tooth 1 and the spiral section is 90°, that is, the section of the slag-breaking tooth perpendicular to the spiral, such as Image 6 , in this device, the angle between the side of the slag breaking tooth 1 and the spiral section is 90°, the contact surface between the slag breaking tooth 1 and the combustion inner cylinder is the largest, the slag breaking effect is the best, and the resistance of the spiral transmission is also relatively large, so the power It consumes a lot.

Embodiment 2

[0048] Example 2: Automatic high-efficiency biomass pellet fuel burner for severe slagging

[0049] In view of the fact that raw materials such as wheat straw and rice straw contain generally high Si elements and other alkali metal elements, and slagging is serious after combustion, a slag breaking and ash cleaning mechanism with an angle of 60° between the side of the slag breaking tooth 1 and the spiral section is used, such as Figure 7 , in this device, the angle between the side of the slag-breaking tooth 1 and the spiral section is 60°, the contact surface between the slag-breaking tooth 1 and the combustion inner cylinder is more, the slag-breaking effect is better, and the resistance of the spiral transmission is also small, so The power consumption is small, which is beneficial to the transmission of ash.

Embodiment 3

[0050] Embodiment 3: General automatic high-efficiency biomass pellet fuel burner for slagging

[0051] For cotton stalks, larch and other raw materials containing low Si elements and other alkali metal elements, less slagging and less ash after combustion, the slag breaking gear with an angle of 45° between the side of the slag breaking tooth 1 and the spiral section is adopted. Cleaning agencies, such as Figure 8 , in this device, the angle between the side of the slag-breaking tooth 1 and the spiral section is 45°, the contact surface between the slag-breaking tooth 1 and the combustion inner cylinder is small, and the slag-breaking effect is general, but the resistance of the spiral transmission is the smallest, so the power consumption Smaller, higher transmission speed of ash.

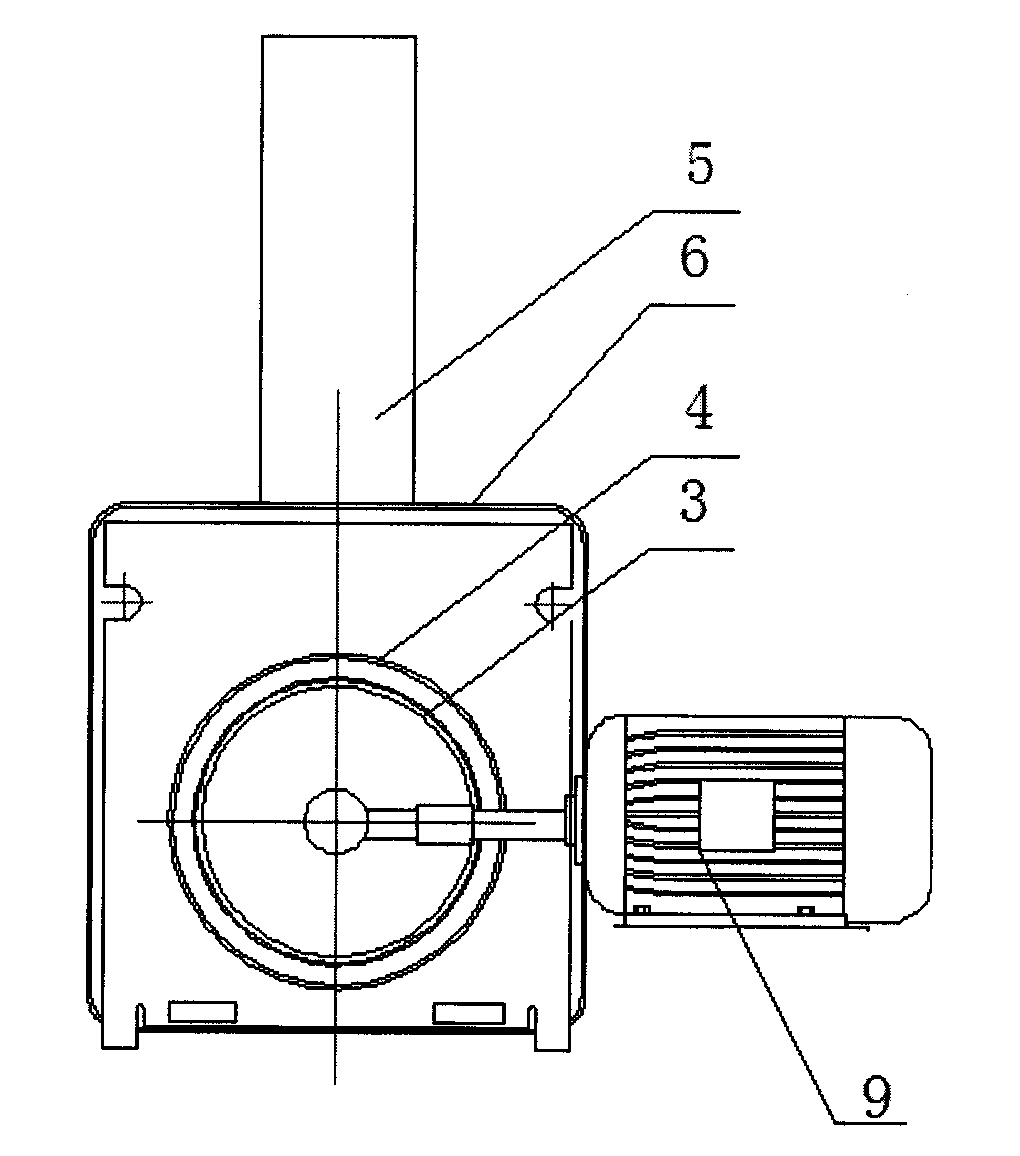

[0052] The automatic high-efficiency biomass pellet fuel burner of the present invention can be installed in various types of biomass boilers. During operation, the drop pipe 5 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com