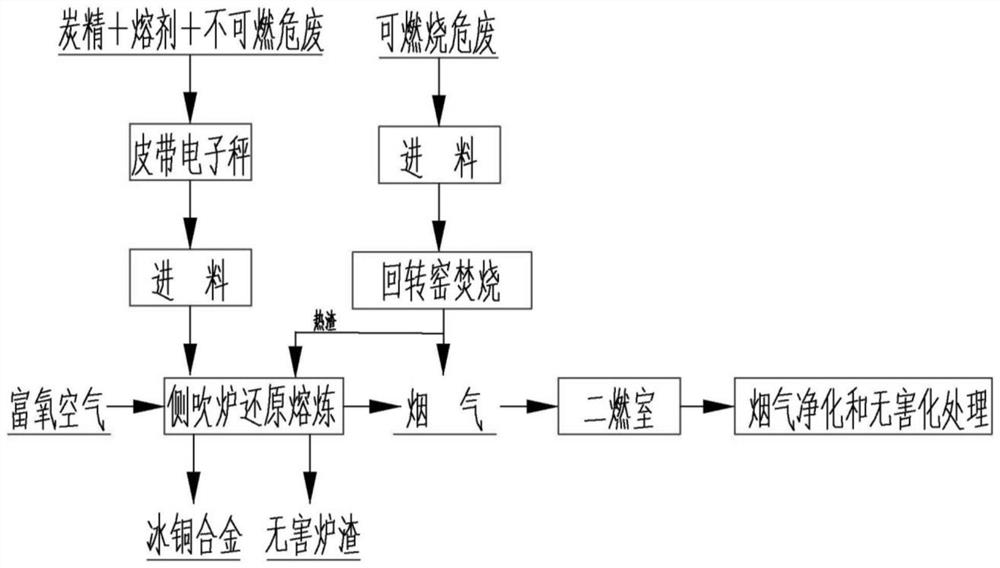

Process method and process device for cooperatively treating hazardous waste through rotary kiln incineration and side-blown converter reduction smelting

A technology of process method and process device, which is applied in the field of hazardous waste treatment and disposal, can solve the problems of large investment, short furnace life, and low recycling rate of hazardous waste resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0098] Example

[0099] Actual production verification

[0100] Zhanjiang City, Suxi County, the same environmental protection technology ship waste treatment center, using rotary kiln incineration and oxygen-rich shunt reduction smelting treatment hazardous waste, annual treatment is 40,000 tons, including HW03 (waste drug drug) 0.2 million tons, HW04 ( Pesticide waste) 01 million tons, HW06 (waste organic solvent and organic flux waste) 0.50,000 tons, HW11 (essential (steam residue) 0.7 million tons, HW12 (dye, coating waste), HW13 (organic resin Waste) 01 million tons, HW18 (incineration disposal residue waste) 0.7 million tons, HW37 (organophosphorus compound waste) 01 million tons, HW39 (phenolic waste) 0.03 million tons, HW40 (containing ether waste) 0.02 million tons, HW49 ( Other waste) is 10,000 tons.

[0101] First, the hazardous waste is brought into the rotary kiln and then incinerated, and the turning kiln is burned. The time of incineration is controlled at 1.5H to 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com