Method for improving combustion thermal efficiency of straw biomass carbon

A biochar and thermal efficiency technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of easy agglomeration and slagging, reduction of harmful gas emissions, etc., to achieve easy agglomeration and slagging, improved combustion thermal efficiency, The effect of accelerating the circulation of oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

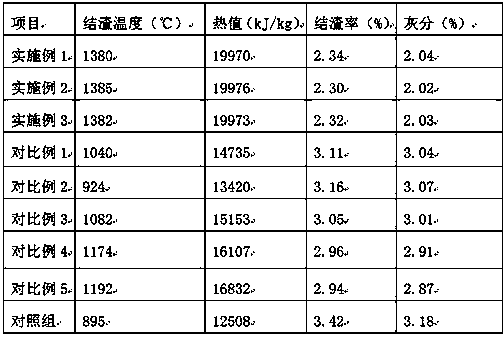

Examples

Embodiment 1

[0019] A method for improving the combustion thermal efficiency of straw-based biomass charcoal. In the production process of biomass charcoal fuel, the prepared sintering aid is mixed into the pretreated biomass straw, and the mixing amount is 1% of the mass of the biomass straw 0.074%, mixed in a high-speed mixer and pressed into blocks, placed in a high-temperature-resistant mica plate container, sent into a muffle furnace for heating, and carbonized. The preparation method of the sintering aid comprises the following steps:

[0020] (1) Weigh 300 grams of white mud powder and 40 grams of silicon nitride fine powder, place them in a vibrating mill and mix for 2 hours, add 2200 milliliters of sodium carbonate aqueous solution under stirring, add 0.45 grams of sodium lauryl sulfate after mixing , continuously stirred for 2 hours, stood still for 6 hours, then centrifuged at 3000 rpm for 30 minutes, poured off the supernatant liquid, and dried the solid precipitate in an oven a...

Embodiment 2

[0030] A method for improving the combustion thermal efficiency of straw-based biomass charcoal. In the production process of biomass charcoal fuel, the prepared sintering aid is mixed into the pretreated biomass straw, and the mixing amount is 1% of the mass of the biomass straw 0.075%, mixed in a high-speed mixer and pressed into blocks, placed in a high-temperature-resistant mica board container, heated in a muffle furnace, and carbonized. The preparation method of the sintering aid comprises the following steps:

[0031] (1) Weigh 305 grams of white clay powder and 42 grams of silicon nitride fine powder, place them in a vibration mill and mix for 2.5 hours, add 2250 milliliters of sodium carbonate aqueous solution under stirring, add 0.46 grams of sodium lauryl sulfate after mixing , continuously stirred for 2.5 hours, stood still for 7 hours, and then centrifuged at 3200 rpm for 35 minutes, poured off the supernatant liquid, and dried the solid precipitate in an oven at 1...

Embodiment 3

[0041] A method for improving the combustion thermal efficiency of straw-based biomass charcoal. In the production process of biomass charcoal fuel, the prepared sintering aid is mixed into the pretreated biomass straw, and the mixing amount is 1% of the mass of the biomass straw 0.076%, mixed in a high-speed mixer and pressed into blocks, placed in a high-temperature-resistant mica board container, sent into a muffle furnace for heating, and carbonized. The preparation method of the sintering aid comprises the following steps:

[0042] (1) Weigh 310 grams of white mud powder and 45 grams of silicon nitride fine powder, place them in a vibration mill and mix for 3 hours, add 2300 milliliters of sodium carbonate aqueous solution under stirring, add 0.47 grams of sodium lauryl sulfate after mixing , continuously stirred for 3 hours, stood still for 8 hours, then centrifuged at 3500 rpm for 40 minutes, poured off the supernatant liquid, and dried the solid precipitate in an oven a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com