Green environment-friendly biomass pellet fuel

A biomass particle, green and environmental protection technology, applied in the direction of biofuel, waste fuel, fuel, etc., to achieve full combustion, improve oxygen capacity, and realize the effect of waste utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

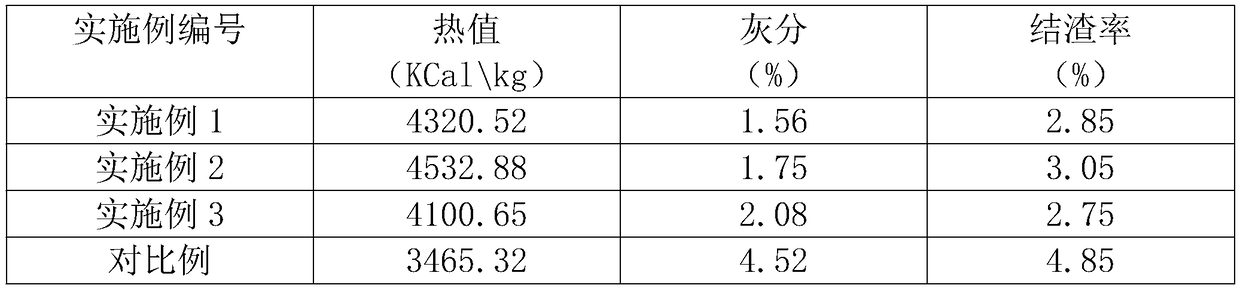

Examples

Embodiment 1

[0020] A green and environment-friendly biomass pellet fuel, which comprises the following raw materials in parts by weight: 60 parts of corn stalks, 33 parts of dead branches, 38 parts of aquatic plants, 2.5 parts of combustion enhancer, 35 parts of wheat straw, 30 parts of rice husks, 0.65 parts of leveling agent, 15 parts of wheat bran, 11 parts of catering waste, and 15 parts of sawdust.

[0021] The combustion aid is potassium nitrate.

[0022] 0.9 part by weight of accelerator is also included.

[0023] It also includes 0.35 parts by weight of potassium permanganate.

[0024] It is made by the following steps:

[0025] Step 1. Put corn stalks, dead branches, aquatic plants, wheat stalks, rice husks, wheat bran, catering waste, and sawdust into a molding machine to make a powder mixture;

[0026] Step 2. Put the powdery mixture prepared in step 1 in an autoclave, add a combustion aid and a leveling agent into the autoclave, adjust the pressure of the autoclave to 0.12M...

Embodiment 2

[0033] A green and environment-friendly biomass pellet fuel, which includes the following raw materials in parts by weight: 57 parts of corn stalks, 50 parts of dead branches, 35 parts of aquatic plants, 2.0 parts of combustion enhancer, 45 parts of wheat straw, 25 parts of rice husks, 0.45 parts of leveling agent, 20 parts of wheat bran, 8 parts of catering waste, and 10 parts of sawdust.

[0034] The combustion aid is potassium nitrate.

[0035] 2.5 parts by weight of accelerator are also included.

[0036] It also includes 0.18 parts by weight of potassium permanganate.

[0037] It is made by the following steps:

[0038] Step 1. Put corn stalks, dead branches, aquatic plants, wheat stalks, rice husks, wheat bran, catering waste, and sawdust into a molding machine to make a powder mixture;

[0039] Step 2. Put the powdery mixture prepared in step 1 in an autoclave, add a combustion aid and a leveling agent into the autoclave, adjust the pressure of the autoclave to 0.10M...

Embodiment 3

[0046]A green and environment-friendly biomass pellet fuel, which includes the following raw materials in parts by weight: 55 parts of corn stalks, 40 parts of dead branches, 40 parts of aquatic plants, 1.2 parts of combustion enhancer, 40 parts of wheat straw, 35 parts of rice husks, 0.33 parts of leveling agent, 17 parts of wheat bran, 13 parts of catering waste, and 5 parts of sawdust.

[0047] The combustion aid is potassium nitrate.

[0048] 1.5 parts by weight of accelerator are also included.

[0049] It also includes 0.42 parts by weight of potassium permanganate.

[0050] It is made by the following steps:

[0051] Step 1. Put corn stalks, dead branches, aquatic plants, wheat stalks, rice husks, wheat bran, catering waste, and sawdust into a molding machine to make a powder mixture;

[0052] Step 2. Put the powdery mixture prepared in step 1 in an autoclave, add a combustion aid and a leveling agent into the autoclave, adjust the pressure of the autoclave to 0.08Mp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com