Rice husk-straw biomass particle

A technology of biomass pellets and rice husks, applied in biofuels, waste fuels, solid fuels, etc., can solve the problems of regional, seasonal structural excess, weakened traditional utilization functions of straw, and unused straw resources. Low ash slagging rate, safe use and less combustion pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

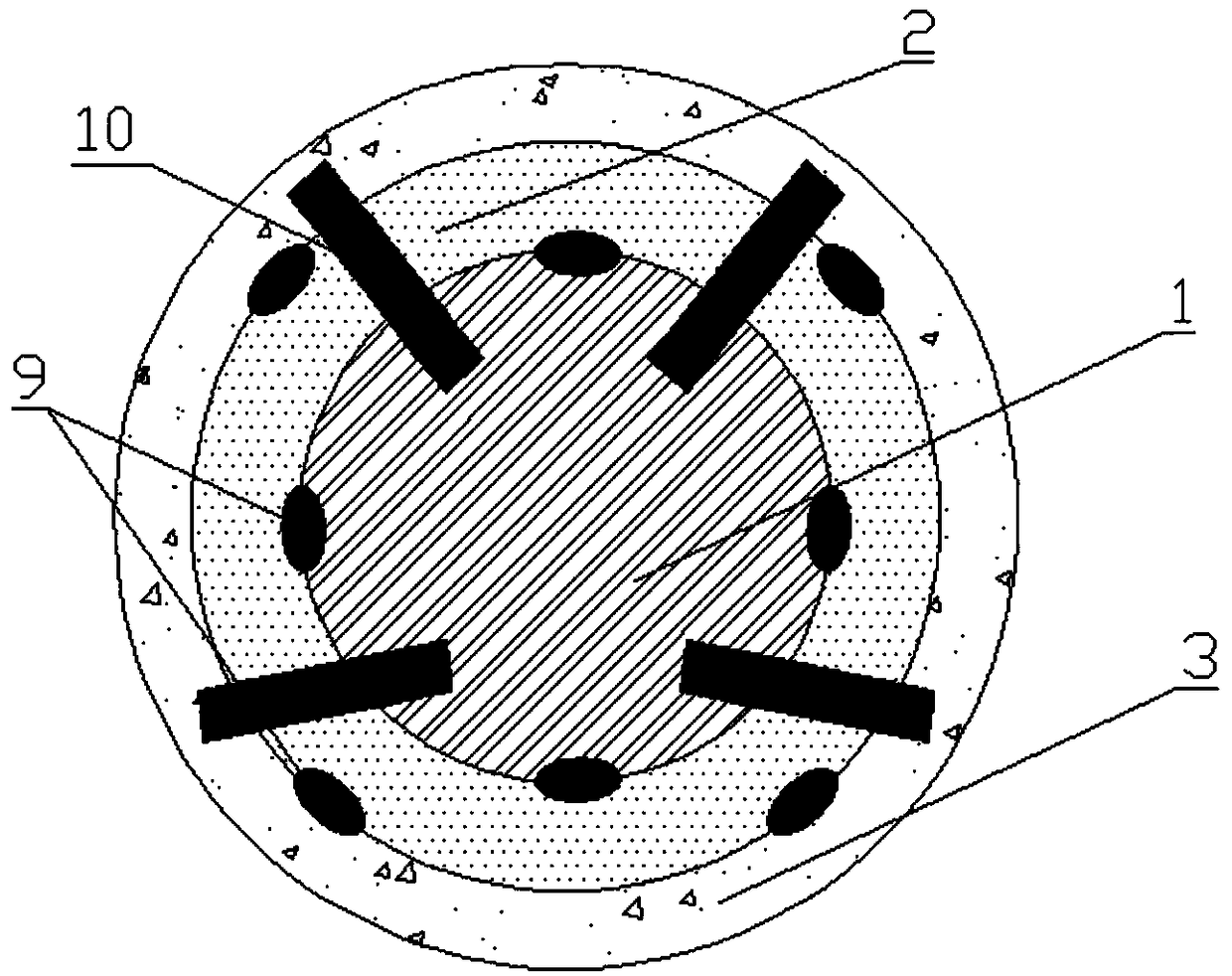

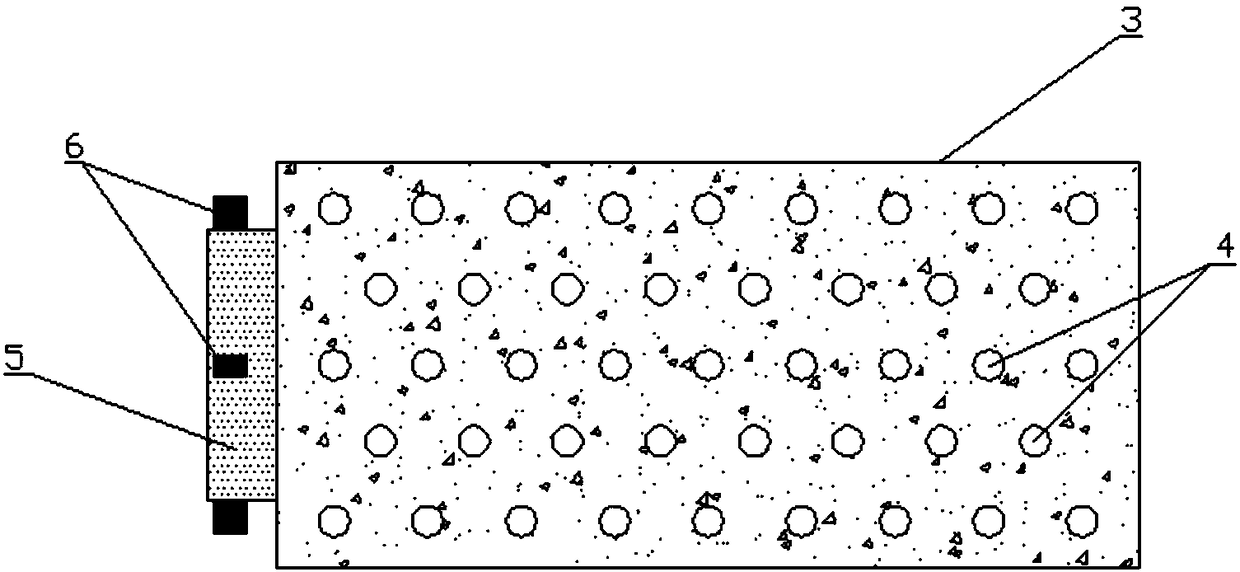

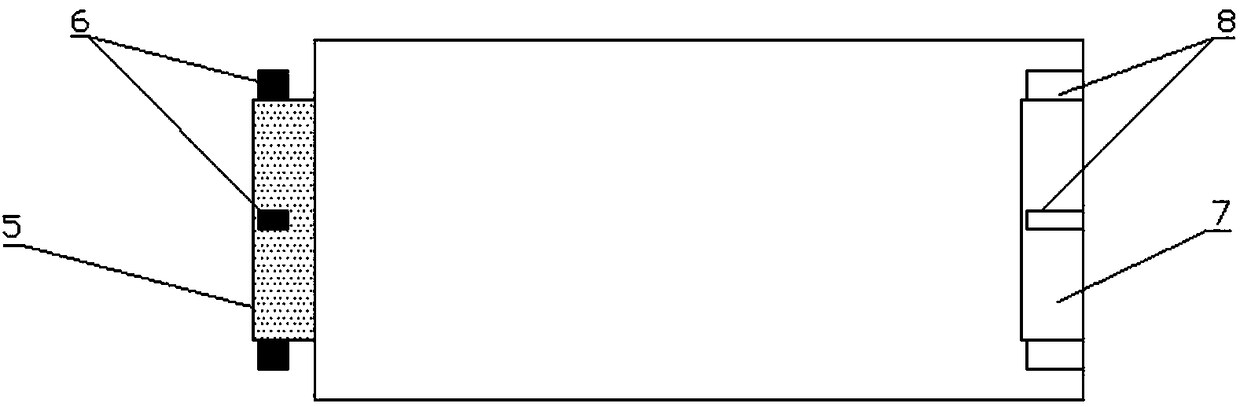

[0020] see Figure 1-3 As shown, the present invention provides a technical solution: a rice husk and straw biomass particle, the biomass particle includes a composite core layer 1, a rice husk layer 2, and a straw layer 3, and the surface layer of the biomass particle is set as straw Layer 3, the inner layer of the straw layer 3 is set as a rice husk layer 2, the inner layer of the rice husk layer 2 is set as a composite core layer 1, and the two ends of the biomass particles are respectively provided with connecting protrusions 5 and A connection groove 7, a connection plug 6 is provided on the connection protrusion 5, a connection socket 8 is opened on the connection groove 7, and a through hole 4 is opened on the surface of the biomass.

[0021] Further, an adhesive 9 is provided between the composite core layer 1 and the rice husk layer 2 and between the rice husk layer 2 and the straw layer 3 .

[0022] Further, reinforcing ribs 10 are installed inside the biomass parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com