Biomass fuel

A biomass fuel, mass ratio technology, applied in the direction of biofuels, waste fuels, fuels, etc., can solve the problems of fuel calorific value and anti-slagging performance to be improved, to improve the microscopic appearance and surface energy, easy to adsorb and Reaction, the effect of reducing the slagging rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

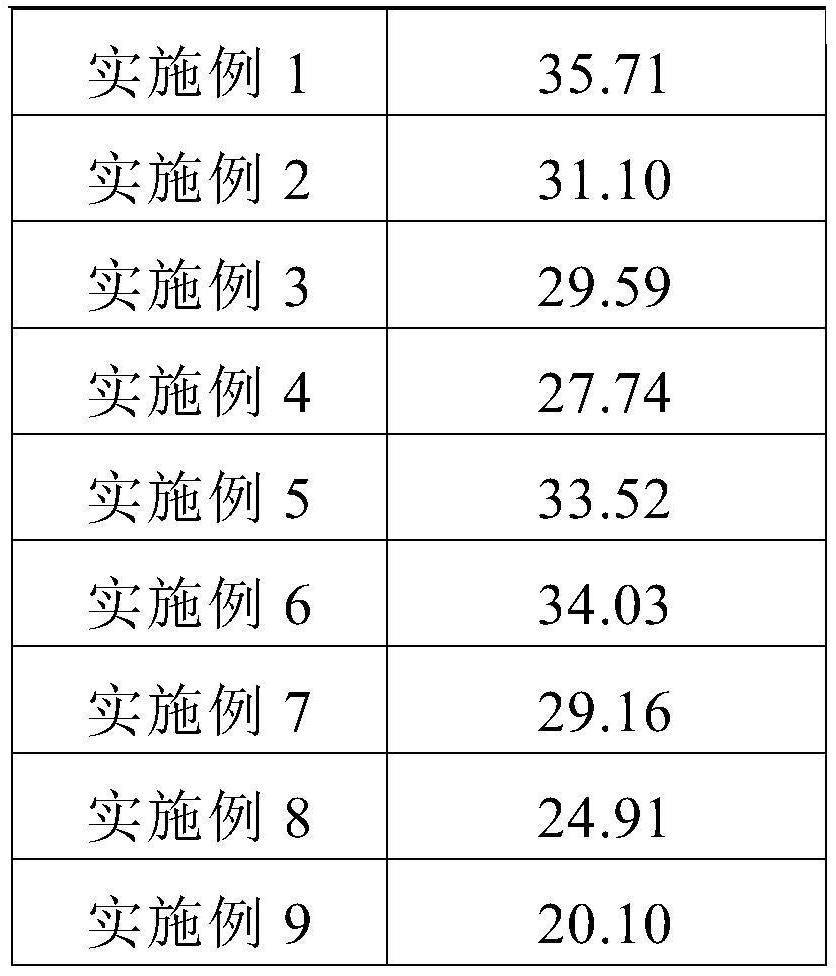

Examples

Embodiment 1

[0046] A method for preparing biomass fuel, comprising the following steps:

[0047] Z1 crushes crop straw residues and dries them to obtain residue powder;

[0048] Z2 Mix the residue powder and anti-slagging agent, then press and cut to obtain granular biomass fuel.

[0049] In the Z1 process: the crop stalk residue is a mixture of bagasse, sorghum stalk, cassava residue, and corn stalk in a mass ratio of 1:1:1:1; the drying temperature is 75°C, and the drying time is 3h; the fiber length of the residue powder is ≤7mm.

[0050] In the Z2 process: the mass ratio of the residue powder to the anti-slagging agent is 19:1; the pressure of the pressing is 13MPa, and the holding time is 35min; the size of the biomass fuel is 2mm×2mm× 2mm.

[0051] The preparation method of described anti-slagging agent is:

[0052] E1 adopts two sizes of alumina grinding balls to dry-grind the ore through a planetary ball mill to obtain ore powder;

[0053] E2 washes the ore powder obtained by...

Embodiment 2

[0061] It is basically the same as Example 1, except that the wetting agent is polyoxyethylene sorbitan laurate.

Embodiment 3

[0063] It is basically the same as Example 1, except that the wetting agent is polyethylene glycol diacrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com