Environment-friendly biomass fuel and preparation method thereof

A biomass fuel, environmental protection technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve problems such as physical and environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] An environmentally friendly biomass fuel, which is made from the following raw materials in parts by mass:

[0060] Calcium lignosulfonate 2g, peanut shell 20g, corn straw 30g, sawdust 10g, biomass charcoal powder 10g, iron oxide 0.2g, limestone powder 3g, soybean straw 30g, pine needle 10g, modified cotton straw 10g, cow dung 10g, 5g of cerium naphthenic acid salt, 11g of anti-coking additive, 0.4g of combustion accelerator, and 12g of binder.

[0061] Wherein, the anti-coking additive includes the following raw material components: 1 g of dolomite, 2 g of olivine, 2 g of colemanite and 6 g of chlorite.

[0062] The combustion promoting agent comprises the following raw material components: 0.1 g of sodium tartrate, 0.2 g of potassium citrate and 0.1 g of sodium fumarate.

[0063] The binder includes the following raw material components: 2 g of bentonite and 10 g of diatomite.

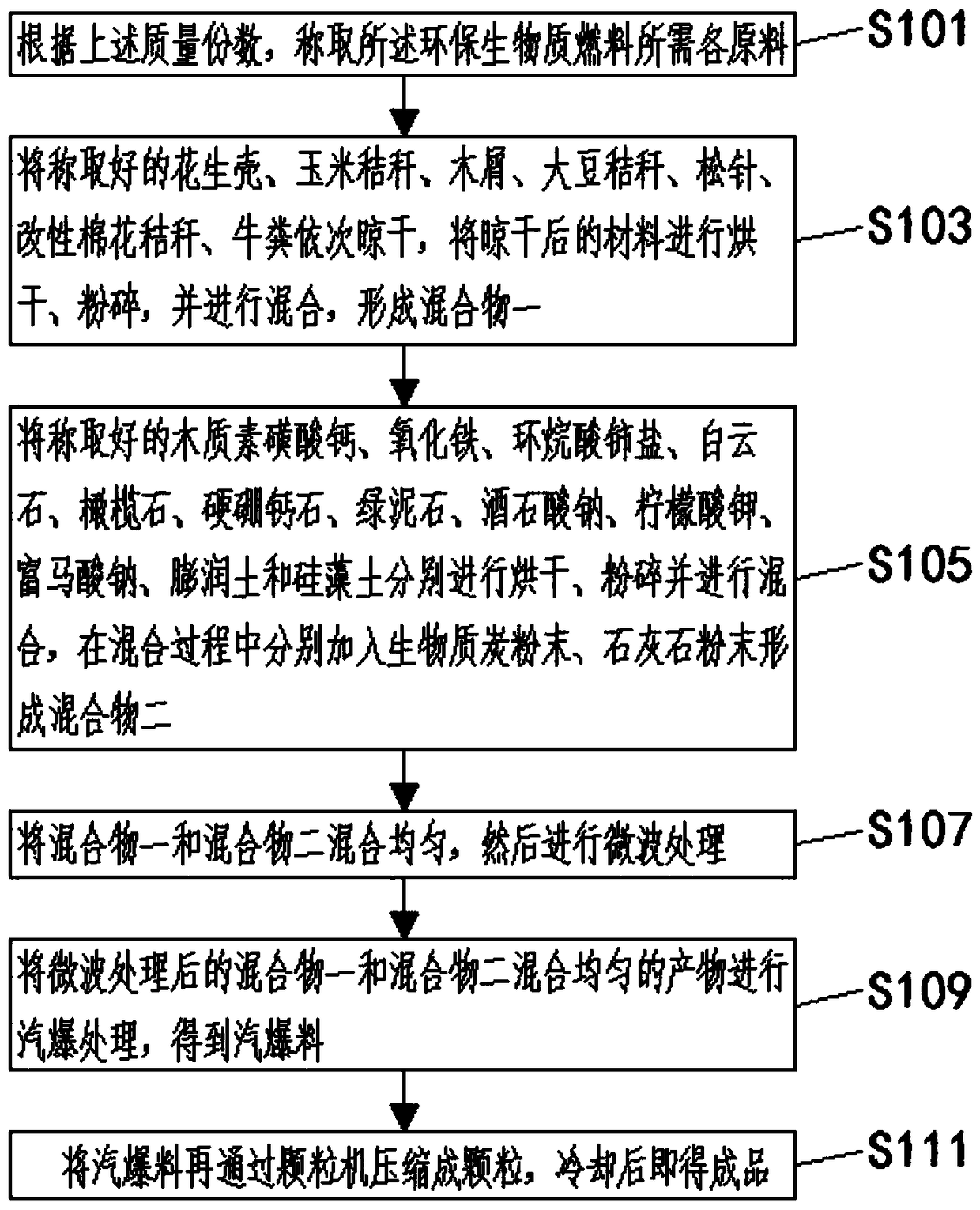

[0064] The preparation of the environment-friendly biomass fuel comprises the following ...

Embodiment 2

[0072] An environmentally friendly biomass fuel, which is made from the following raw materials in parts by mass:

[0073] Calcium lignosulfonate 3g, peanut shell 25g, corn straw 40g, sawdust 15g, biomass charcoal powder 15g, iron oxide 0.4g, limestone powder 5g, soybean straw 40g, pine needle 15g, modified cotton straw 13g, cow dung 18g, 6g of cerium naphthenate, 16g of anti-coking additive, 0.9g of combustion accelerator, and 15g of binder.

[0074] Wherein, the anti-coking additive includes the following raw material components: 2g of dolomite, 3g of olivine, 4g of colemanite and 7g of chlorite.

[0075] The combustion promoting agent comprises the following raw material components: 0.2 g of sodium tartrate, 0.3 g of potassium citrate and 0.2 g of sodium fumarate.

[0076] The binder includes the following raw material components: 4g of bentonite and 11g of diatomite.

[0077] The preparation of the environment-friendly biomass fuel comprises the following steps:

[0078...

Embodiment 3

[0085] Calcium lignosulfonate 4g, peanut shell 30g, corn straw 50g, sawdust 20g, biomass charcoal powder 20g, iron oxide 0.6g, limestone powder 7g, soybean straw 50g, pine needle 20g, modified cotton straw 16g, cow dung 25g, 7g of cerium naphthenate, 21g of anti-coking additive, 1.4g of combustion accelerator, and 18g of binder.

[0086] Wherein, the anti-coking additive includes the following raw material components: 3g of dolomite, 4g of olivine, 6g of colemanite and 8g of chlorite.

[0087] The combustion promoting agent comprises the following raw material components: 0.3 g of sodium tartrate, 0.4 g of potassium citrate and 0.3 g of sodium fumarate.

[0088] The binder includes the following raw material components: 6g of bentonite and 12g of diatomite.

[0089] The preparation of the environment-friendly biomass fuel comprises the following steps:

[0090] According to the above-mentioned mass parts, each raw material required for the environmentally friendly biomass fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com