Biomass fuel with mildew-proof function

A biomass fuel and functional technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve problems such as easy mold, affecting combustion efficiency, and high ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A biomass fuel with anti-mold function, prepared from the following raw materials in parts by weight: 30-40 parts of camphor tree leaves, 20-30 parts of tea stems, 25-35 parts of bamboo charcoal powder, and 8-12 parts of attapulgite clay powder .

[0013] The preparation method of the biomass fuel with anti-mildew function as described above may further comprise the steps:

[0014] (1) Crush camphor leaves and tea stalks and pass through a 80-120 mesh sieve;

[0015] (2) Mix the crushed camphor leaves, tea stalks, bamboo charcoal powder and attapulgite clay powder evenly;

[0016] (3) Extruded by pellet machine.

Embodiment 2

[0018] A biomass fuel with anti-mold function is prepared from the following raw materials in parts by weight: 35 parts of camphor tree leaves, 25 parts of green tea stems, 30 parts of bamboo charcoal powder, and 10 parts of attapulgite clay powder.

[0019] The preparation method of the biomass fuel with anti-mildew function as described above may further comprise the steps:

[0020] (1) Crush camphor leaves and green tea stalks and pass through a 120-mesh sieve;

[0021] (2) Mix the crushed camphor leaves, tea stalks, bamboo charcoal powder and attapulgite clay powder evenly;

[0022] (3) Extruded by pellet machine.

Embodiment 3

[0024] A biomass fuel with anti-mold function is prepared from the following raw materials in parts by weight: 36 parts of camphor tree leaves, 24 parts of green tea stems, 29 parts of bamboo charcoal powder, and 12 parts of attapulgite clay powder.

[0025] The preparation method of the biomass fuel with anti-mildew function as described above may further comprise the steps:

[0026] (1) Crush camphor leaves and green tea stalks and pass through a 120-mesh sieve;

[0027] (2) Mix the crushed camphor leaves, tea stalks, bamboo charcoal powder and attapulgite clay powder evenly;

[0028] (3) Extruded by pellet machine.

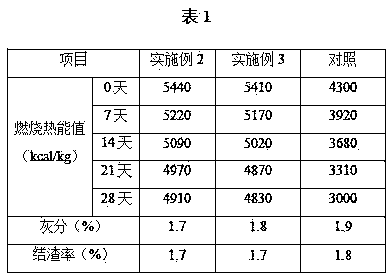

[0029] Taking the briquette obtained in Example 2-3 as a sample, compared with the commercially available briquette, the combustion performance was tested, and the above sample was placed in an 80% humidity environment, and some samples were taken out every 7 days for testing. The results are shown in the table 1:

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com