Biomass particles with high combustion rate

A technology of biomass particles and combustion rate, which is applied in the direction of biofuels, fuels, solid fuels, etc., to achieve the effects of wide sources, increased calorific value per unit volume, and good combustibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

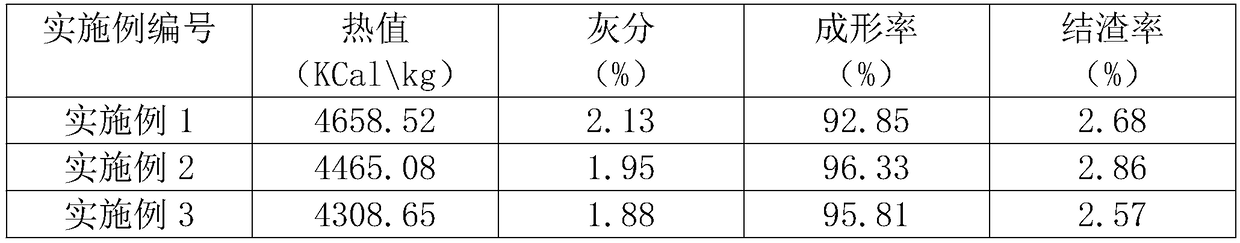

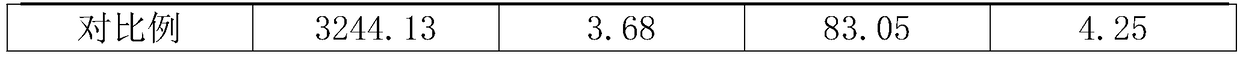

Embodiment 1

[0018] A biomass particle with a high combustion rate, which includes the following raw materials in parts by weight: 25 parts of corn stalks, 40 parts of soybean stalks, 20 parts of rice husks, 9 parts of poultry manure, 12 parts of Bupleurum dregs, and Radix Radix 16 parts of slag, 0.12 parts of ammonium perchlorate, and 5 parts of paraffin.

[0019] It also includes 0.65 parts by weight of an initiator.

[0020] The initiator is one or a combination of two or more of benzoyl peroxide, hydrogen peroxide, and tert-butyl hydroperoxide.

[0021] It is made by the following steps:

[0022] Step 1. Put corn stalks, soybean stalks, rice husks, poultry manure, bupleurum dregs, and isatis root dregs into a molding machine to make a powdery mixture;

[0023] Step 2, put the powdery mixture prepared in step 1 in an autoclave, and add ammonium perchlorate and paraffin to the autoclave, adjust the pressure of the autoclave to 0.11Mpa, the temperature to 36°C, and stir evenly to obtain...

Embodiment 2

[0029] A biomass particle with a high combustion rate, which includes the following raw materials in parts by weight: 35 parts of corn stalks, 45 parts of soybean stalks, 12 parts of rice husks, 12 parts of poultry manure, 15 parts of Bupleurum dregs, and Radix Radix 10 parts of slag, 0.14 parts of ammonium perchlorate, and 7 parts of paraffin.

[0030] It also includes 0.33 parts by weight of an initiator.

[0031] The initiator is one or a combination of two or more of benzoyl peroxide, hydrogen peroxide, and tert-butyl hydroperoxide.

[0032] It is made by the following steps:

[0033] Step 1. Put corn stalks, soybean stalks, rice husks, poultry manure, bupleurum dregs, and isatis root dregs into a molding machine to make a powdery mixture;

[0034] Step 2, placing the powdered mixture obtained in step 1 in an autoclave, and adding ammonium perchlorate, paraffin, and sodium nitrite in parts by weight to the autoclave, and the sodium nitrite is decomposed into oxygen by he...

Embodiment 3

[0040] A biomass granule with a high combustion rate, which includes the following raw materials in parts by weight: 40 parts of corn stalks, 35 parts of soybean stalks, 15 parts of rice husks, 15 parts of poultry manure, 10 parts of Bupleurum dregs, and Radix Radix 13 parts of slag, 0.16 parts of ammonium perchlorate, and 2 parts of paraffin.

[0041] It also includes 0.42 parts by weight of an initiator.

[0042] The initiator is one or a combination of two or more of benzoyl peroxide, hydrogen peroxide, and tert-butyl hydroperoxide.

[0043] It is made by the following steps:

[0044] Step 1. Put corn stalks, soybean stalks, rice husks, poultry manure, bupleurum dregs, and isatis root dregs into a molding machine to make a powdery mixture;

[0045] Step 2, put the powdery mixture prepared in step 1 in an autoclave, and add ammonium perchlorate and paraffin to the autoclave, adjust the pressure of the autoclave to 0.16Mpa, the temperature to 33°C, and stir evenly to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com