Biomass solid forming fuel additive

A solid molding fuel and additive technology, applied in the direction of solid fuel, fuel, petroleum industry, etc., can solve the problems of easy slagging of biomass solid molding fuel, low fuel utilization and combustion efficiency, corrosion of combustion equipment, etc., to increase additional value, increase utilization, and reduce corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

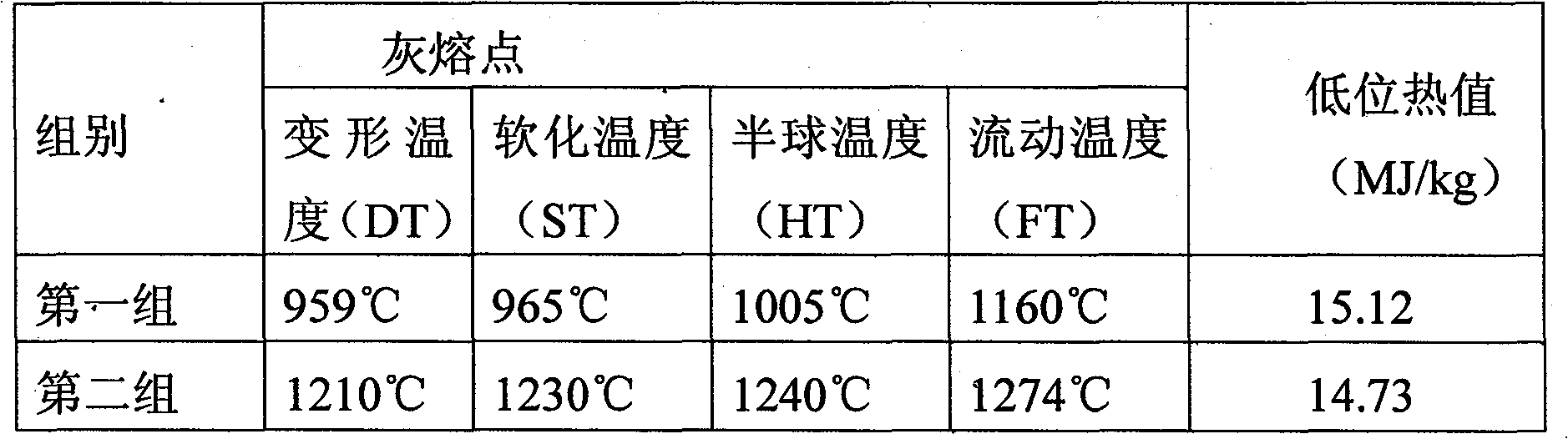

[0011] Specific embodiment 1: In this embodiment, the biomass solid molding fuel additive consists of 20% to 30% Al by weight percentage 2 o 3 , 15% to 30% Fe 2 o 3 It is mixed with 40% to 65% kaolin.

[0012] During the straw burning process, the biomass solid briquette fuel additive in this embodiment can react with alkali metal salts and chlorides to generate high melting point substances, thereby achieving the effect of improving the ash melting point and making the ash melting characteristics of the straw biomass solid briquette fuel close to medium coal.

[0013] Due to the addition of the biomass solid molding fuel additive in this embodiment, the ash melting point of the straw biomass solid molding fuel has been significantly improved, so it can also be co-fired with garbage and coal for power generation and heat supply, which broadens the scope of straw biomass solid molding. Fuel usage range.

specific Embodiment approach 2

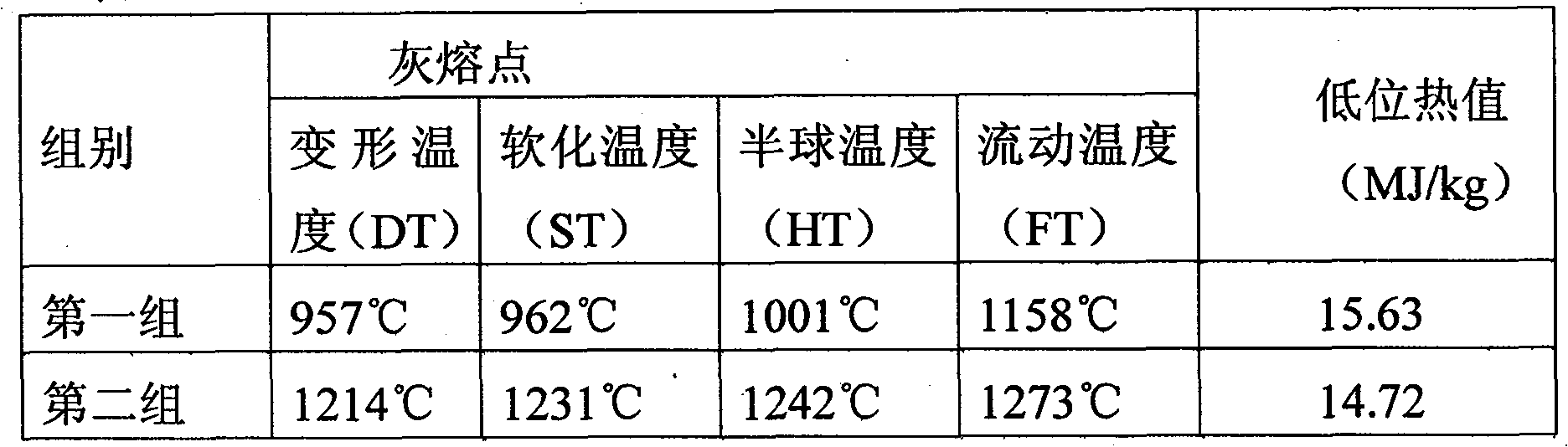

[0014] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the biomass solid molding fuel additive consists of 22% to 28% Al by weight percentage 2 o 3 , 17% to 28% Fe 2 o 3 It is mixed with 44% to 61% kaolin. Others are the same as the first embodiment.

specific Embodiment approach 3

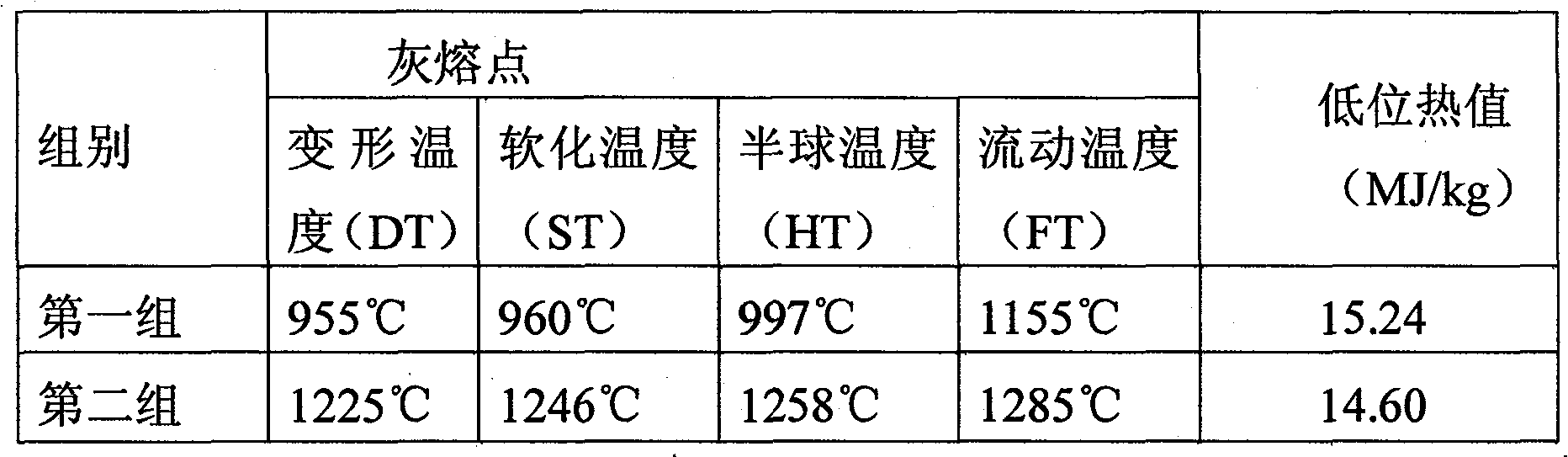

[0015] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the biomass solid molding fuel additive is made of 25% Al by weight percentage 2 o 3 , 20% Fe 2 o 3 And 55% kaolin mixed composition. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| combustion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com