Poly-generation method employing coupling of biomass with livestock and poultry manure

A technology of livestock and poultry manure and polygeneration, which is applied in the field of comprehensive utilization of biomass and livestock and poultry manure, can solve the problems of different degrees of antibiotic absorption and utilization, soil, environment, air pollution, antibiotic abuse, etc., so as to improve soil variability. Effects of organic carbon content, improving ecological environment, and increasing soil carbon sinks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Combined preparation of electricity, heat, cold, biogas and organic fertilizer by using yellow stalks and chicken manure, including the following steps:

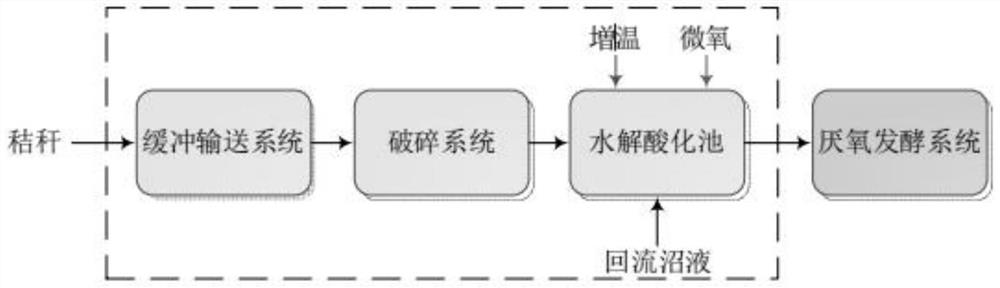

[0039] S1. Straw burning: crush the yellow storage straw to 1cm, put it into the acidification tank equipped with organic acid acetic acid bacteria, gram-negative bacilli, glucose oxidizing bacteria and Trichoderma for hydrolysis and acidification, and send it into direct-fired straw power generation water-cooled vibration Grate boiler, combustion power generation, while providing steam and heat for the preparation of bio-natural gas;

[0040] S2. Raw material pretreatment:

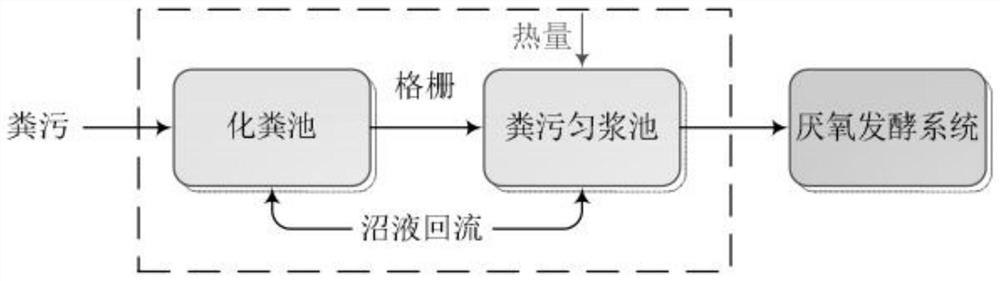

[0041] Livestock and poultry manure: chicken manure is mixed with reflux biogas slurry in the septic tank for septic homogenization treatment, the mixed septic flows through the mechanical grid, and then enters the manure homogenization tank for further homogenization, and is heated and hydrolyzed treatment, the hydrolysis temperature is 50°C, a...

Embodiment 2

[0050] Combined preparation of electricity, heat, cold, biogas and organic fertilizer by adopting silage straw and cow dung, including the following steps:

[0051] S1. Straw burning: crush the silage straw to 1cm, put it into the acidification tank equipped with organic acid acetic acid bacteria, gram-negative bacilli, glucose oxidizing bacteria and Trichoderma for hydrolysis and acidification, and send it to the direct-fired straw power generation water-cooled vibrating furnace Boiler row, combustion power generation, while providing steam and heat for the preparation of bio-natural gas;

[0052] S2. Raw material pretreatment:

[0053] Livestock and poultry manure: the cow manure is mixed with the return biogas slurry in the septic tank for septic homogenization treatment, the mixed septic flows through the mechanical grid, and then enters the manure homogenization tank for further homogenization, and is heated and hydrolyzed treatment, the hydrolysis temperature is 80°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com