Code-scanning rear-mounted logistics sorting system

A sorting system and rear-mounted technology, which is applied in sorting and other directions, can solve the problems of low efficiency, poor reliability, and low space utilization of the sorting line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

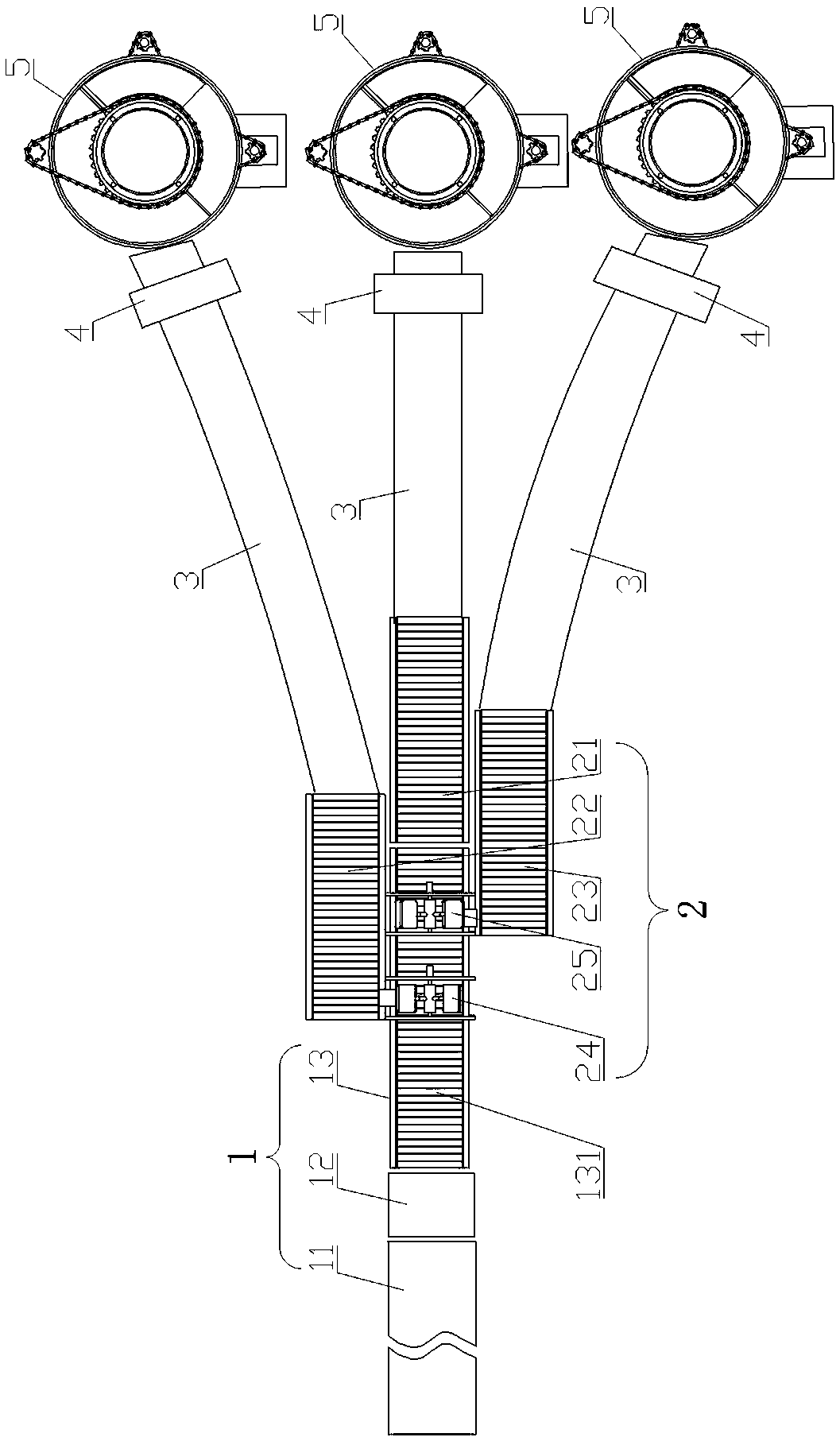

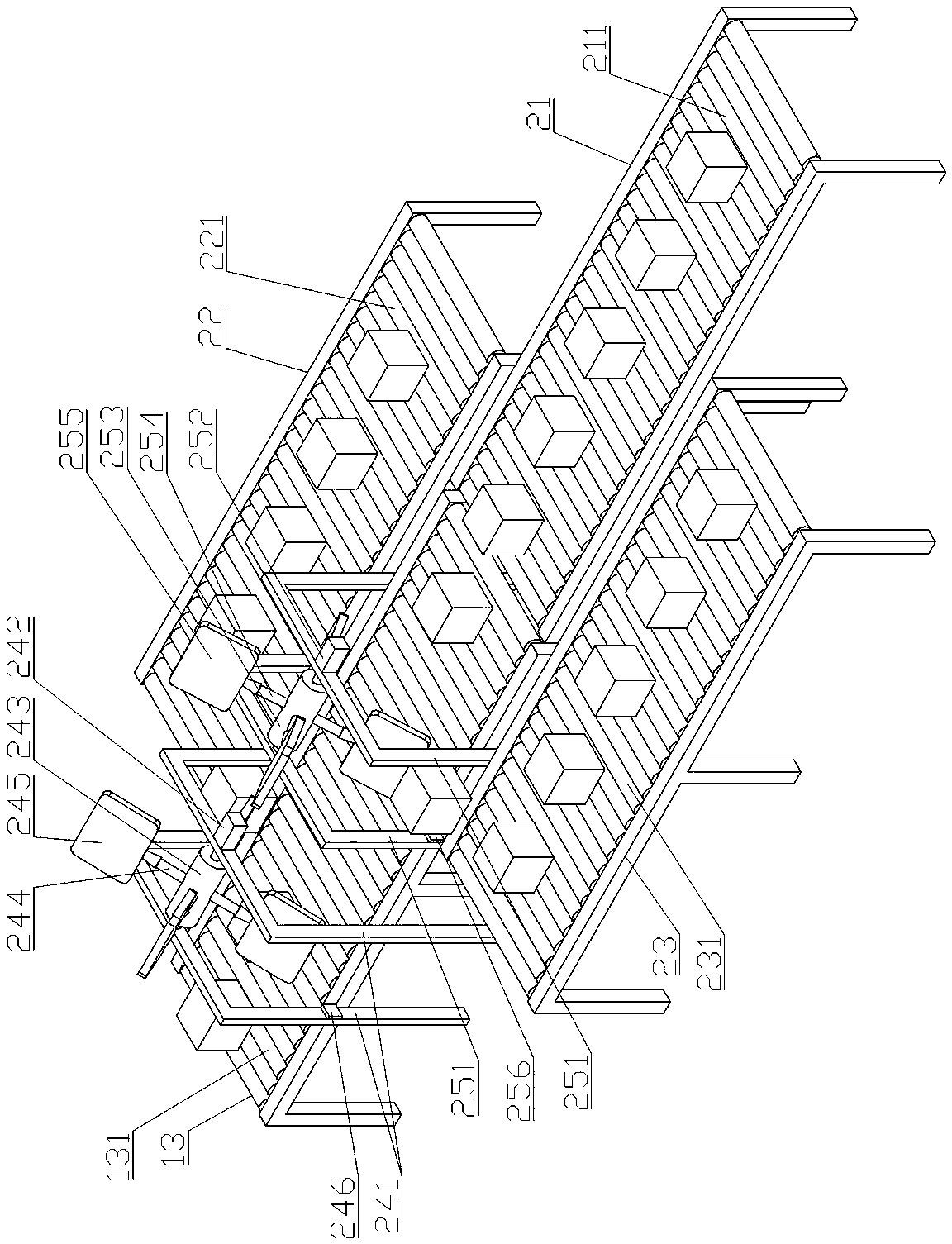

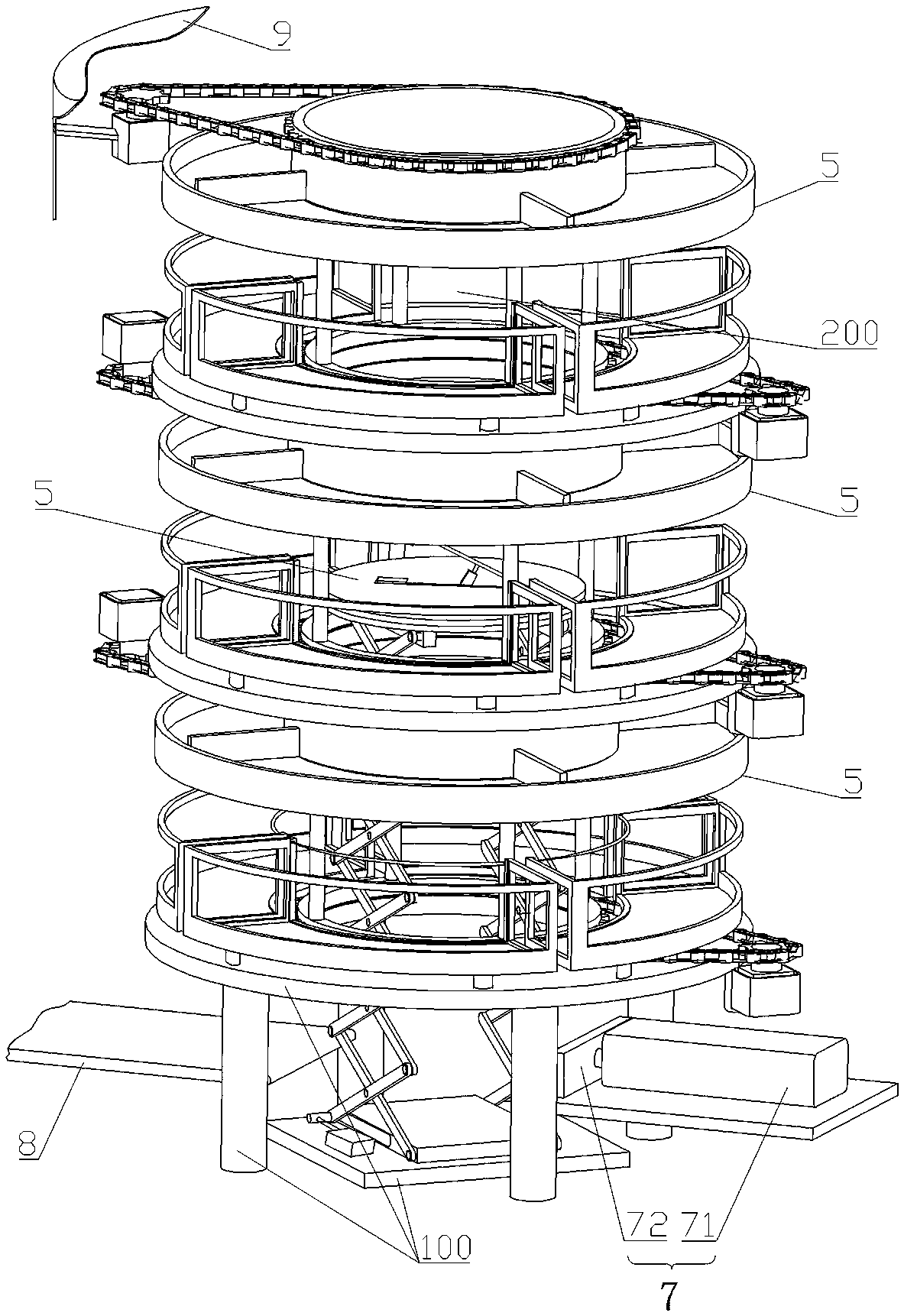

[0080] Such as Figure 1-14 As shown, the code-scanning rear-mounted logistics sorting system includes a picking and separating device 1, a three-way diverter 2, a diverting conveyor 3, a code-scanning device 4, a tower sorting device and a controller.

[0081] The picking and separating device 1 includes a conveyor A11 , a smooth separating plate 12 and a roller conveying device 13 which are arranged next to each other from front to back. The roller conveying device 13 includes a plurality of juxtaposed and horizontally arranged rollers and a roller driving mechanism (not shown) for driving all the rollers to rotate synchronously. The roller conveying mechanism is a chain transmission pair driven by a motor. All the rollers form a rolling transmission surface 131 at the upper end, the height of the rolling transmission surface 131 is not higher than the height of the upper surface of the smooth separation plate 12, and the height of the upper surface of the smooth separation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com