Novel tab rubberizing device

A gluing device and lug technology, which is applied to electrical components, climate sustainability, non-aqueous electrolyte batteries, etc., can solve problems such as the discharge of defective products, affecting the yield rate, and the single gluing standard, so as to ensure the yield rate, The effect of reducing the probability of dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

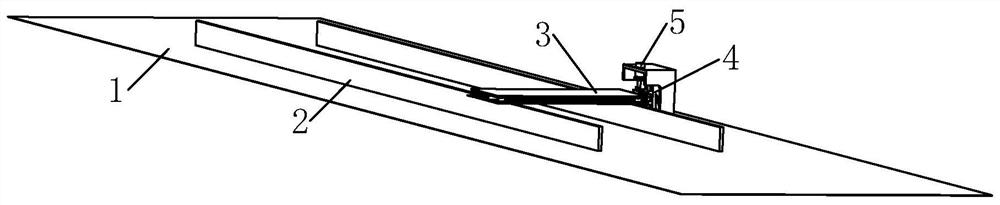

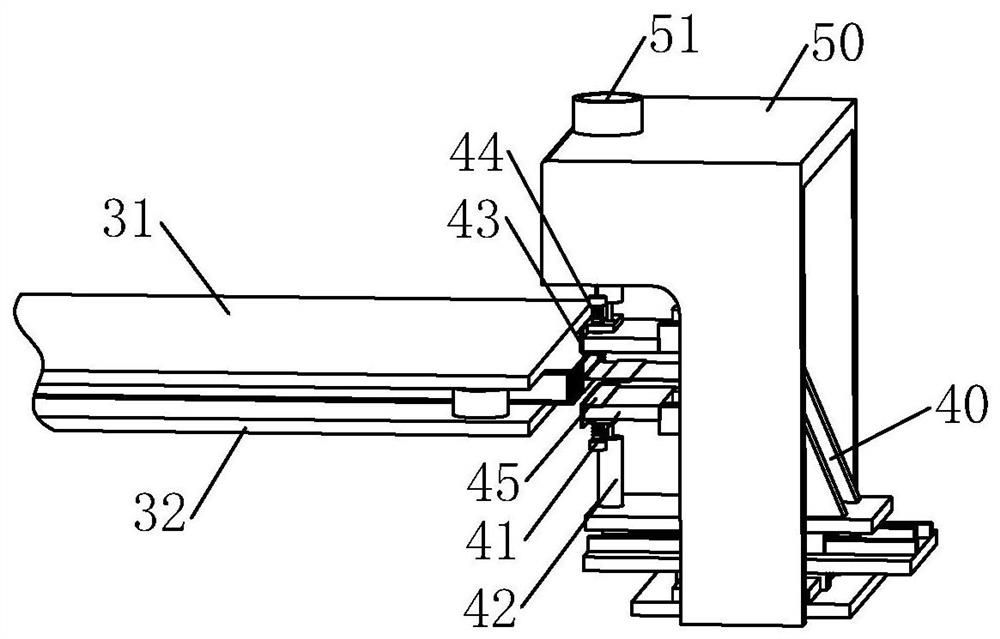

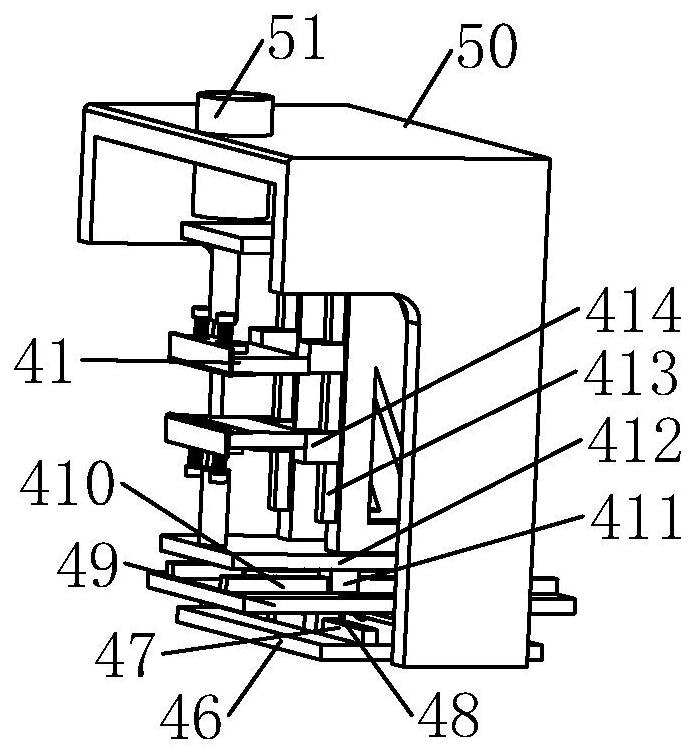

[0024] Example: such as Figure 1 to Figure 6 As shown, a new tab gluing device includes a substrate 1. In order to ensure the stability of the tab gluing device and the accuracy of gluing, the substrate 1 is usually arranged in a planar plate shape. The logistics line 2 for carrying and moving the lithium battery 6 is installed on the above-mentioned substrate 1. In order to further ensure the stability of the tab glue device, there are at least two logistics lines 2, and the two logistics lines 2 are arranged in parallel with each other. In order to ensure the accuracy of the gluing position, a detection mechanism 5 is provided on the top of the above-mentioned gluing mechanism 4, and the detection mechanism 5 includes a detection bracket. 50 and a CCD detector 51, the detection bracket 50 is arranged in an inverted "L" shape, and the CCD detector 51 is installed on the top of the detection bracket 50. In order to ensure the stability of the CCD detector 51 during the insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com