Camera cover machining clamp

A camera and fixture technology, used in manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve problems such as camera cover exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

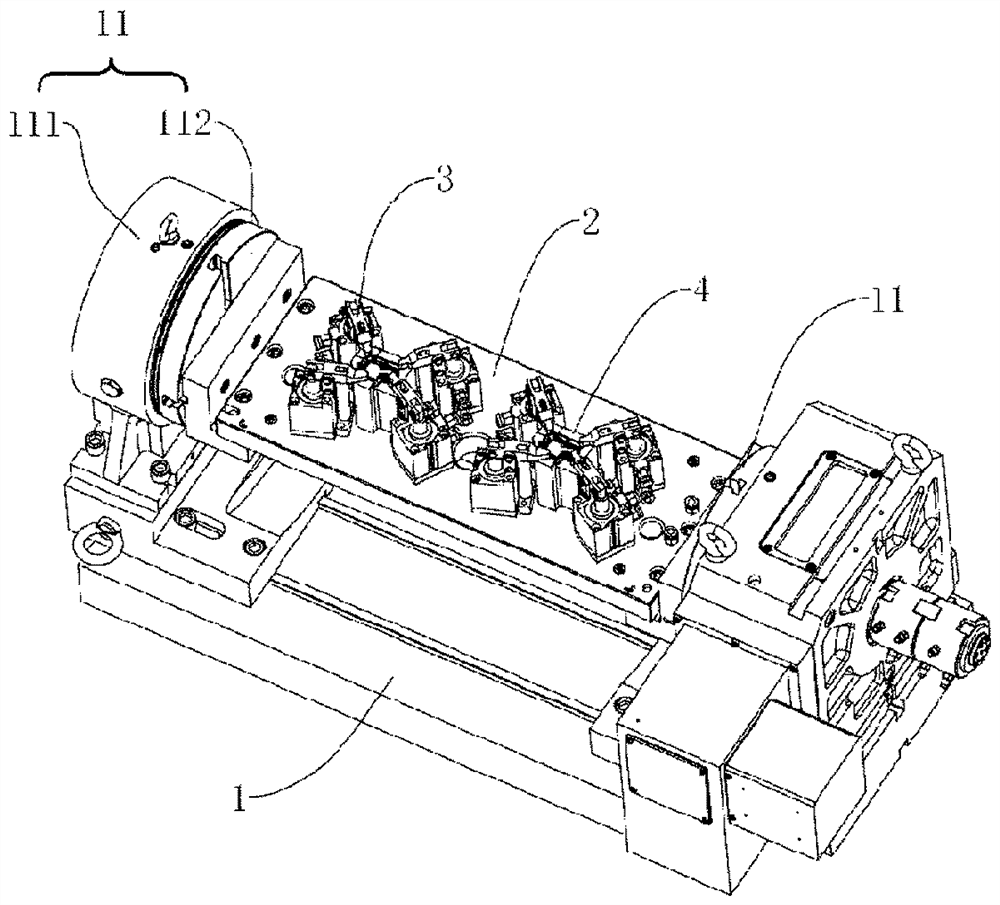

[0042] refer to figure 1 , the camera cover processing jig includes a machine table 1, a rotating seat 11, a driving mechanism, a support plate 2, a pressing assembly 3 and a positioning block 4, the rotating seat 11 is slidably connected with the machine table 1, and the rotating seat 11 includes a seat body 111 and a seat body 111 rotates the connected turntable 112, the turntable 11 is arranged at both ends of the support plate 2 and the turntable 112 and the support plate 2 are connected by bolts. The driving mechanism includes a motor, and the motor is used to drive a turntable 112 to rotate.

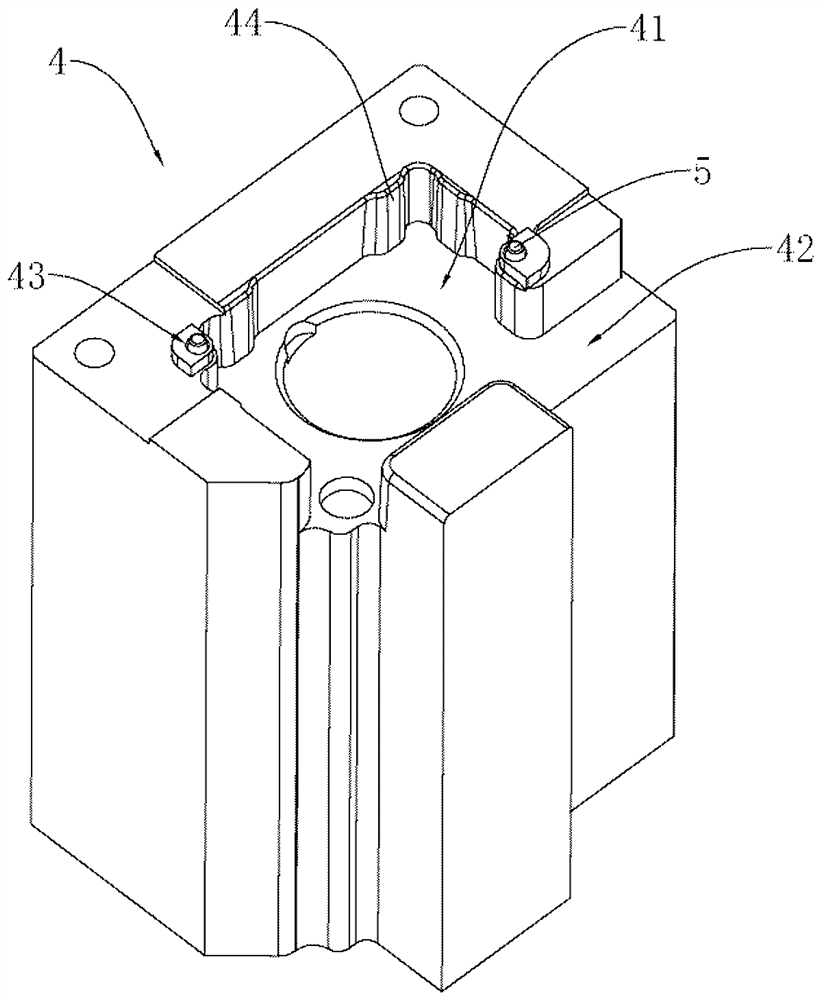

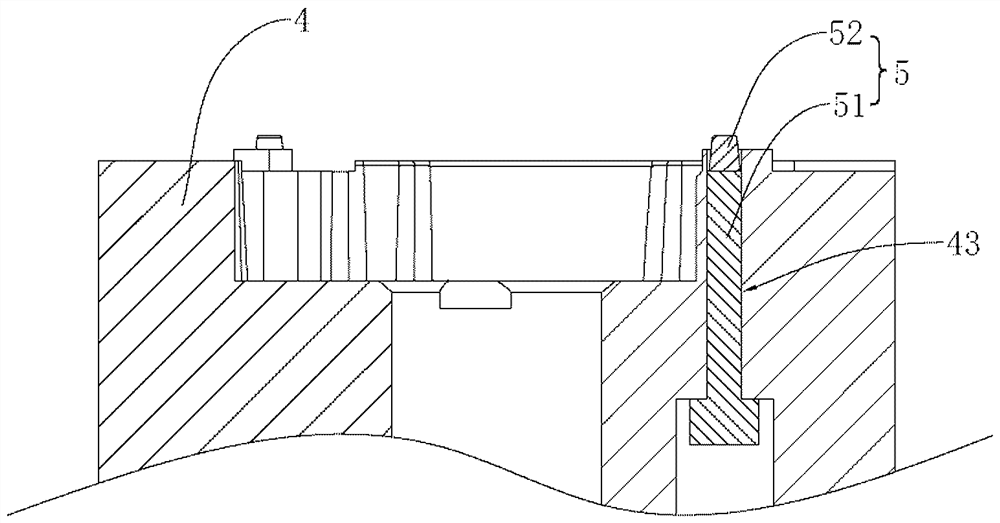

[0043] refer to figure 1 with figure 2 , the positioning block 4 is installed on the support plate 2 through bolts. In this embodiment, there are four groups of pressing components 3 and they are respectively located around the positioning block 4. The positioning block 4 is provided with a positioning cavity 41 for placing the camera cover. Positioning A limiting block 44 is a...

Embodiment 2

[0047] refer to Figure 5 with Image 6 The difference between this embodiment and Embodiment 1 is that the pressing assembly 3 includes a pressing plate 31 and an oil cylinder 32 for driving the pressing plate 31 up and down. The pressing plate 31 includes a plate body 312 and pressing teeth 313. The pressing teeth 313 are used to press the camera cover. The plate body 312 and the pressing teeth 313 are integrally formed. of the circumferential surface. The piston rod of the oil cylinder 32 is rotationally connected to the plate body 312 through a thrust roller bearing.

[0048] refer to Figure 5 with Image 6 , the drive assembly also includes a power part, the power part includes a rotating wheel 71, a motor and a reducer connected to the motor, the motor and the reducer form a power source 72 that drives the rotating wheel 71 to rotate. The rotating wheel 71 includes a circular plate 711 and vertical rods 712 arranged on the circular plate 711 . The circular plate 71...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com