Film residue picker

A residual film pick-up and residual film technology, used in collectors, harvesters, agricultural machinery and implements, etc., can solve the problems affecting the work efficiency of residual film pickers, soil being bundled, and film shovel blockage, etc. Working range, convenient transportation, the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

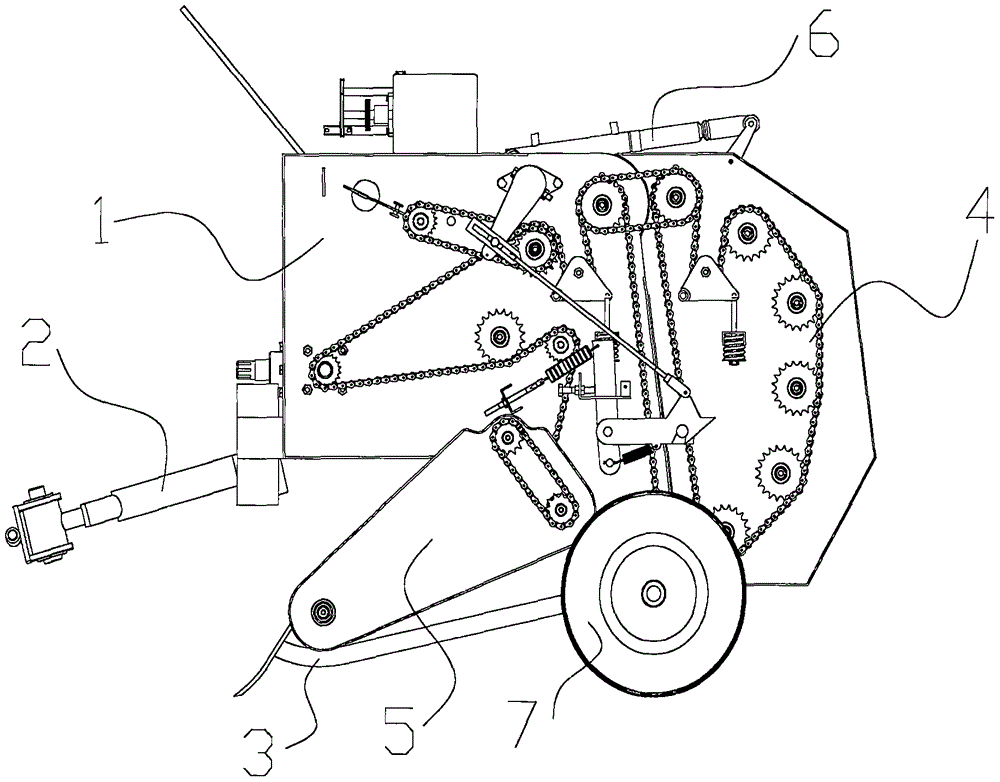

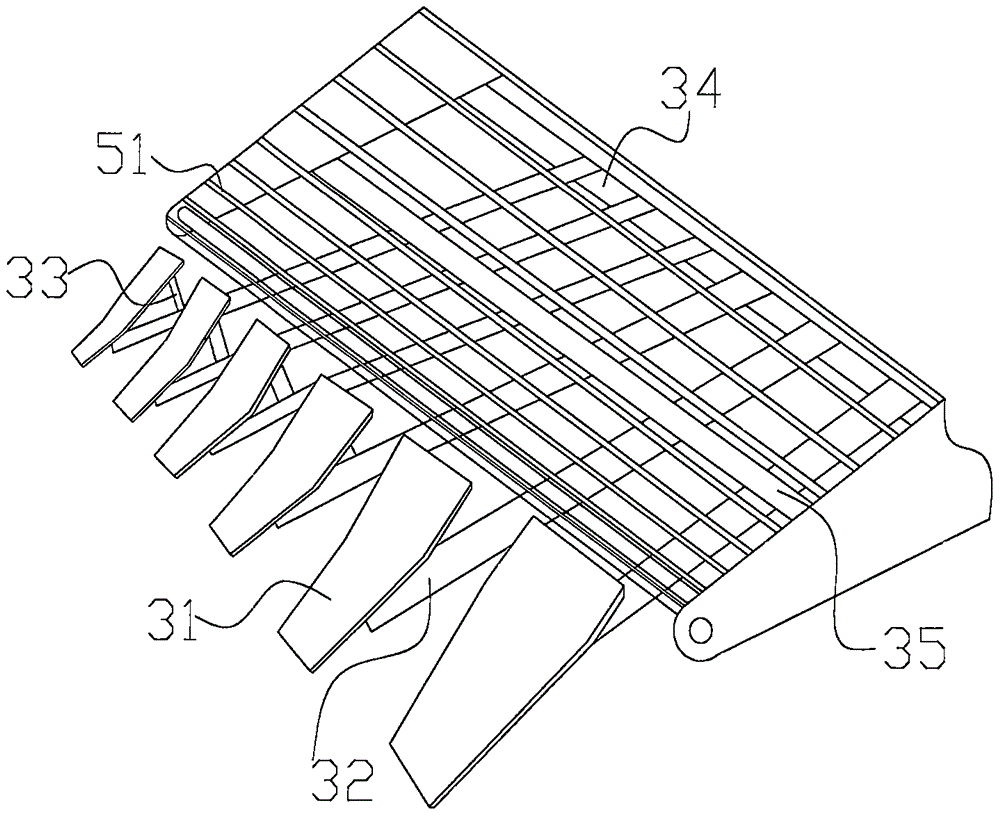

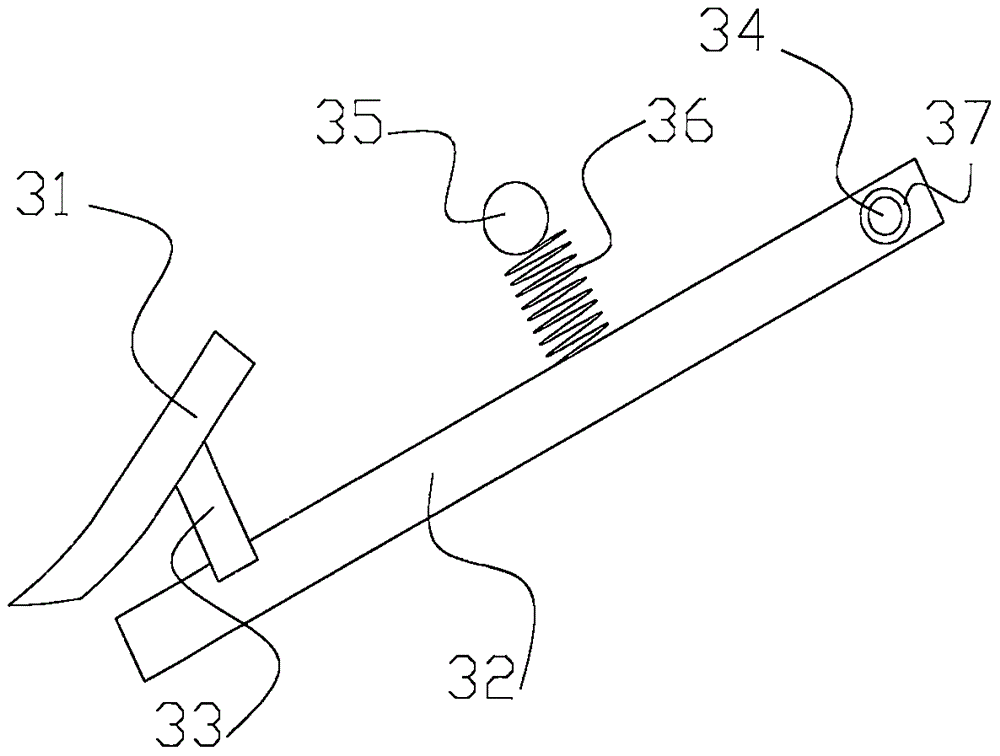

[0025] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a residual film picking machine includes a machine body 1, and the machine 1 is provided with a traction device 2, a film lifting device 3, a residual film conveying device and a walking device 7, and the residual film conveying device is a chain lifting device 5 , The film lifting device 3 is located at the front position of the chain lifting device 5, and the rear portion of the chain lifting device 5 is also provided with a bundling device 4, and the bundling device 4 is connected with a film unloading device 6; the structure of the above It is designed so that the residual film scooped up by the film lifting device 3 directly enters the chain elevator de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com