System and method for aseptic filling of packages with liquid products

A technology of aseptic filling and packaging, which is applied in the direction of sterilization/aseptic filling operation, packaging, liquid treatment, etc., which can solve the problems that rigid containers cannot be used, are not suitable for filling devices, and are not suitable, so as to reduce equipment and filling costs, maximum safety, and increased utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

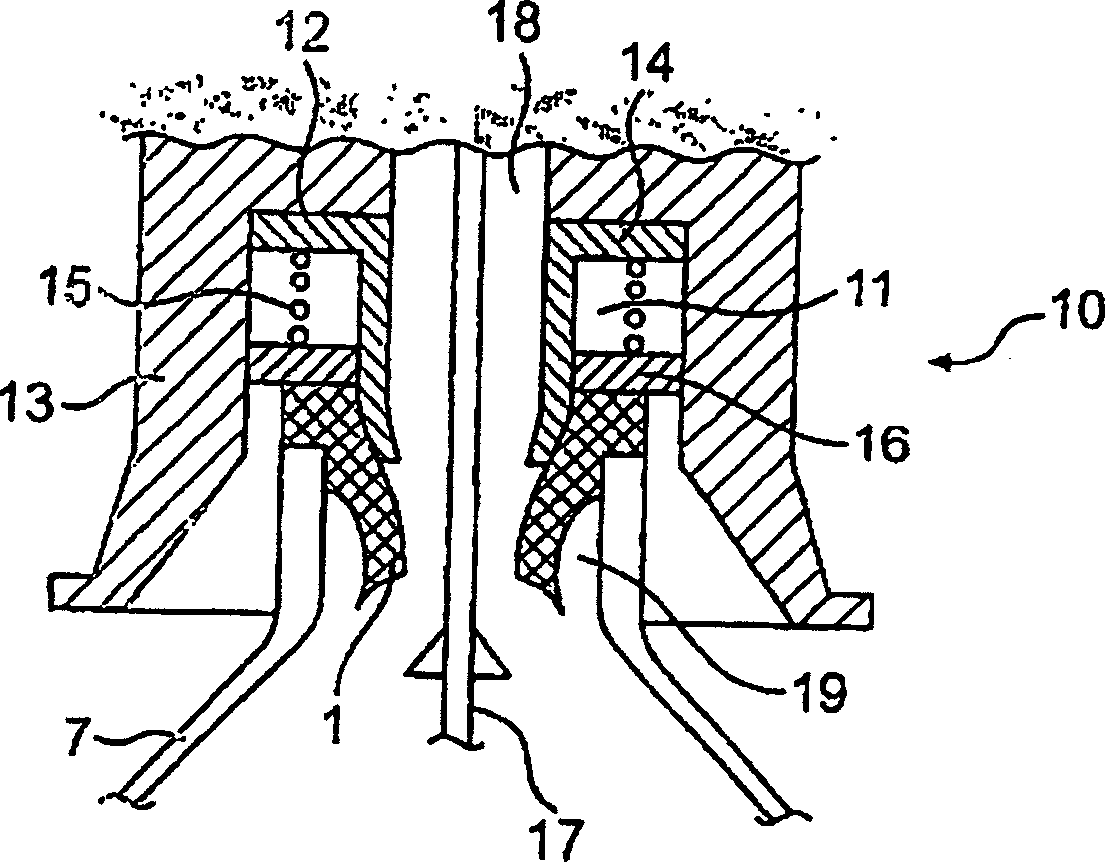

[0032] Although the following drawings and description illustrate one embodiment of the present invention in which the bottle is an aseptic filling container, those skilled in the art should understand that the principles of the present invention can be simply applied to the tank with the same advantageous results. And other containers.

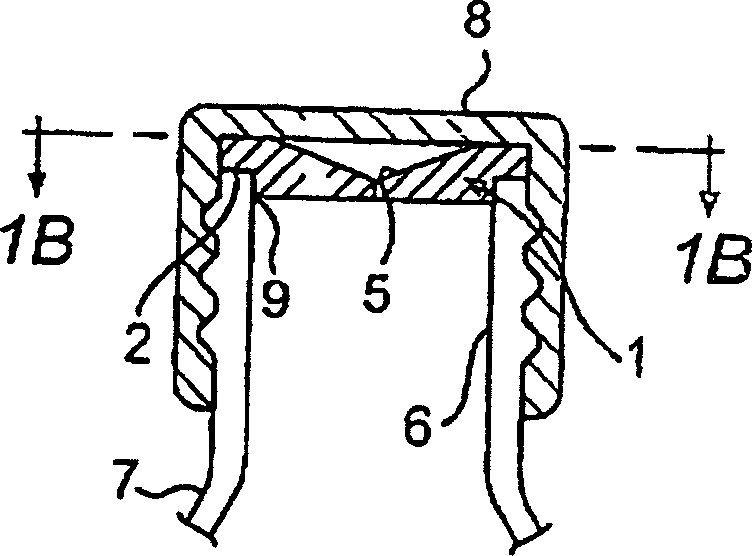

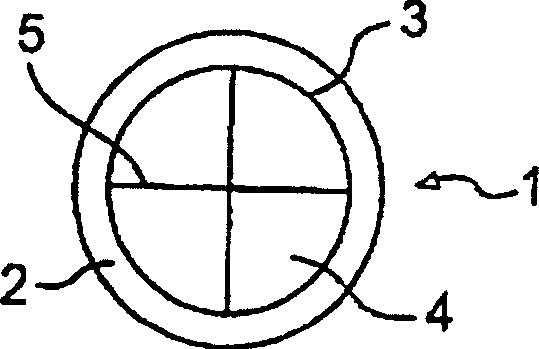

[0033] Figure 1 shows an embodiment of the film. The film 1 can be made of suitable flexible and product compatible materials, for example, made of a suitable grade of silicone rubber. In FIG. 1, the film 1 may have an outer edge 2 and an inner part 3 including a plurality of sectors 4. The sector 4 may be divided by a plurality of lips 5. The lips 5 may be designed to be combined with each other so as to be properly airtight. The film 1 can be installed on the opening 6 of the package 7.

[0034]In Figure 1, the package 7 is shown as a bottle, but similar principles can be applied to cans and other hollow packages. After filling, a cover 8 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com