Rising large inclination angle belt conveyor of common rubber belt

A technology of belt conveyors and conveyors, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as unsuitable for high-yield and high-efficiency material transportation, belt running speed limit, and increased manufacturing costs, etc., to achieve The effect of shortening the project construction period, reducing project and equipment cost, and reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and examples.

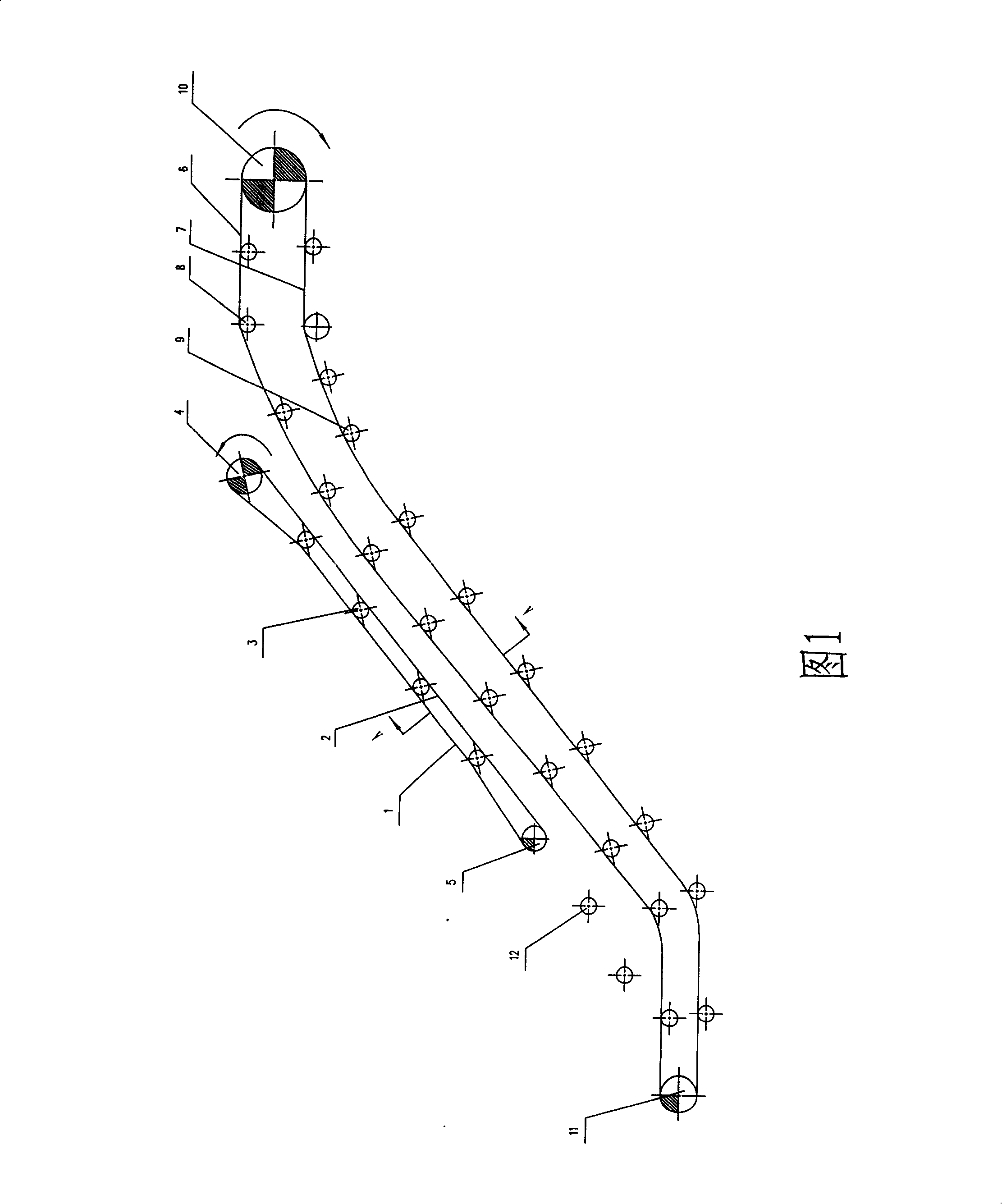

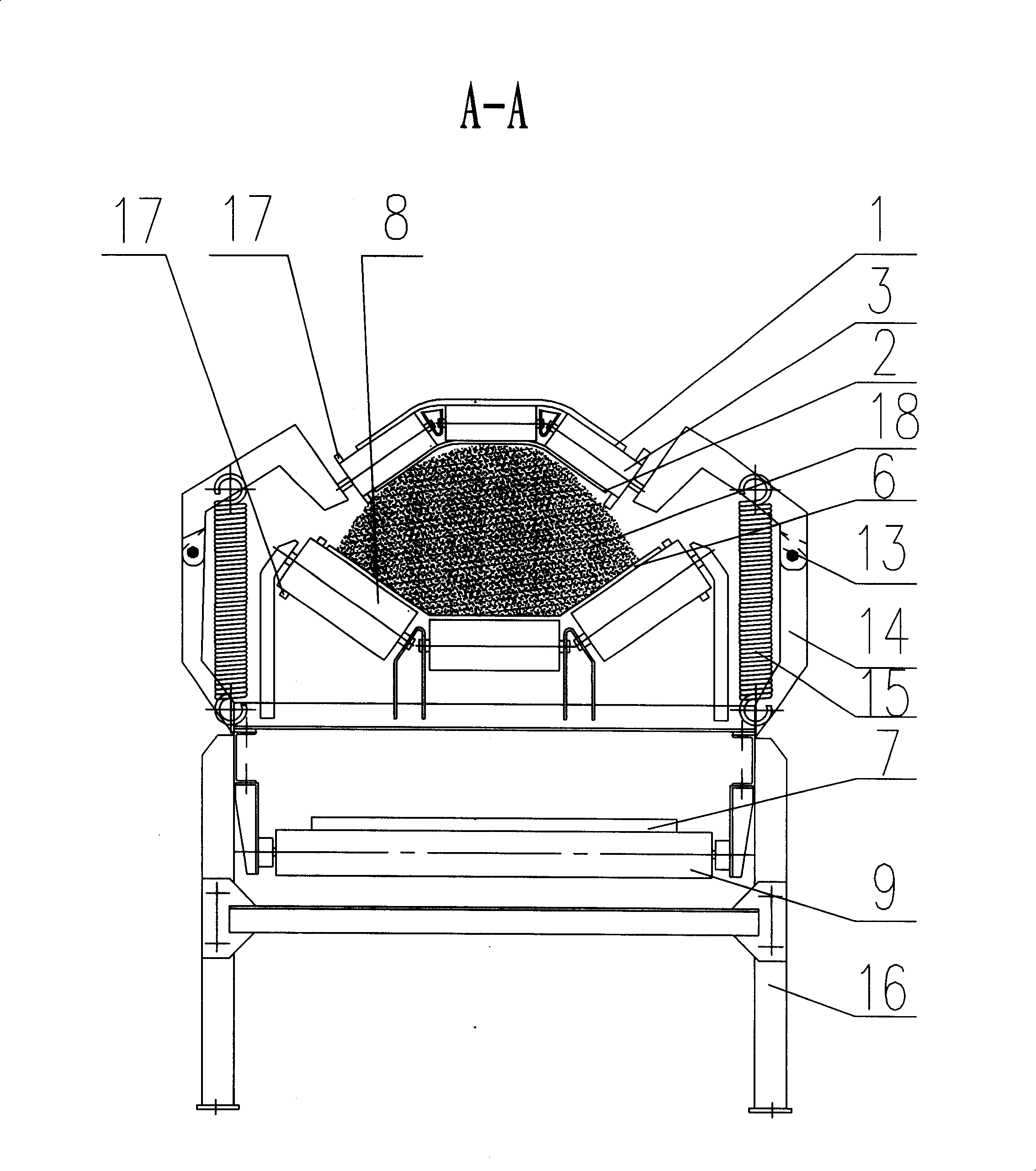

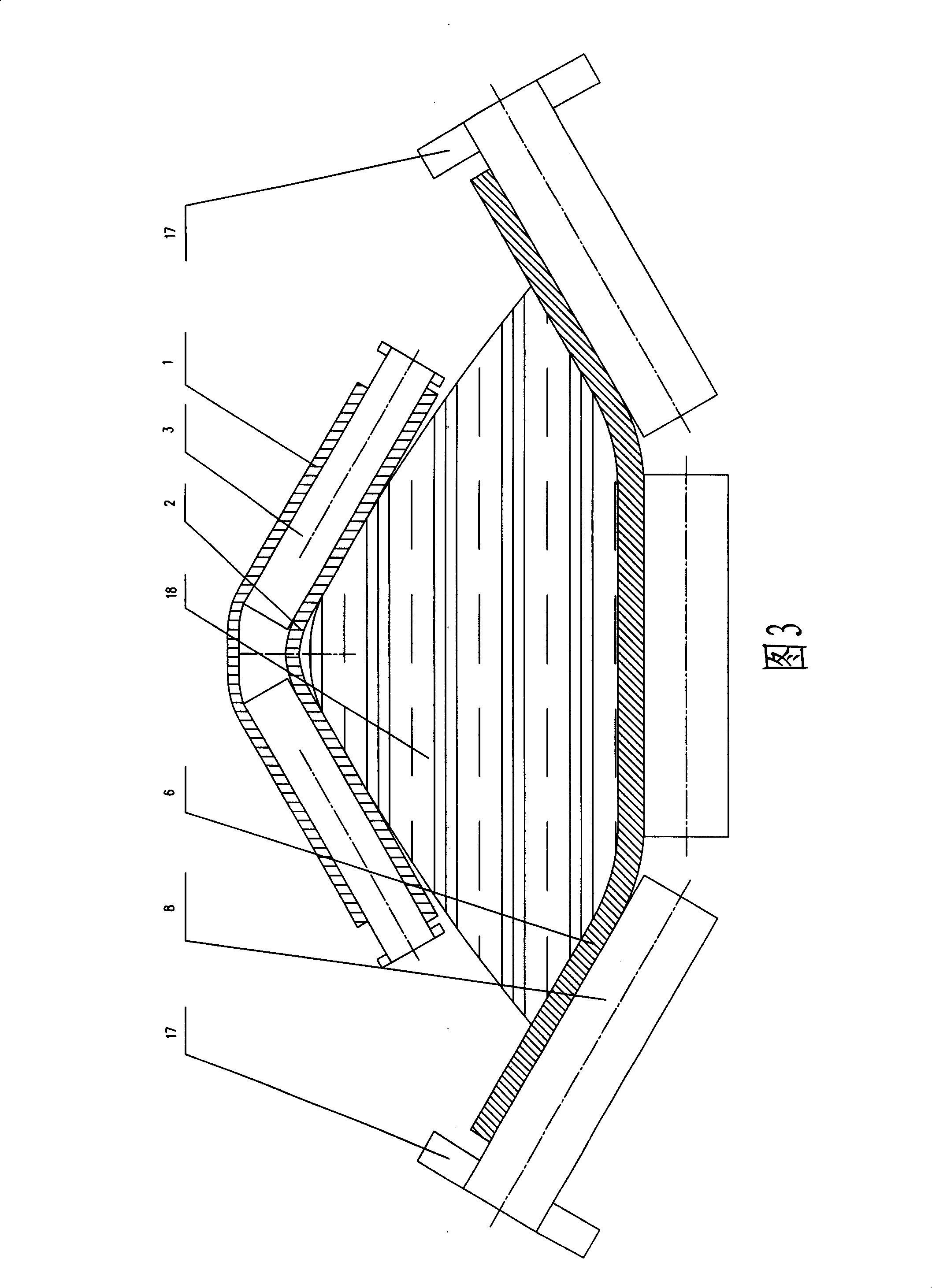

[0019] Fig. 1 is the front view of the present invention, in the figure 1 is the return pressure tape, 2 is the pressing pressure tape, 3 is the support roller of the pressure tape, 4 and 5 are respectively the drive roller and the redirecting roller of the pressure tape; 6 is the upper Conveyor carrying material belt with an inclination angle of +25°-60°, 7 is the return belt of the conveyor, 8 is the grooved roller of the conveyor, 9 is the flat roller of the conveyor, 10 and 11 are the driving rollers of the conveyor respectively With reversing drum, 12 is a power idler. figure 2 It is the A-A sectional view of FIG. 1 . In the figure, 1 is the return pressure belt, 2 is the pressing pressure belt, 3 is the supporting pressure belt idler (inverted groove shape), 6 is the conveyor material belt arranged at an upward inclination angle, 7 is the return bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com