Process and system thereof for forming upgraded lignite

A molding process, lignite technology, applied in the petroleum industry, solid fuel, fuel, etc., can solve the problems of poor system stability, low safety performance, environmental pollution, etc., achieve the simplification of the return process, save investment costs, and reduce dust pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

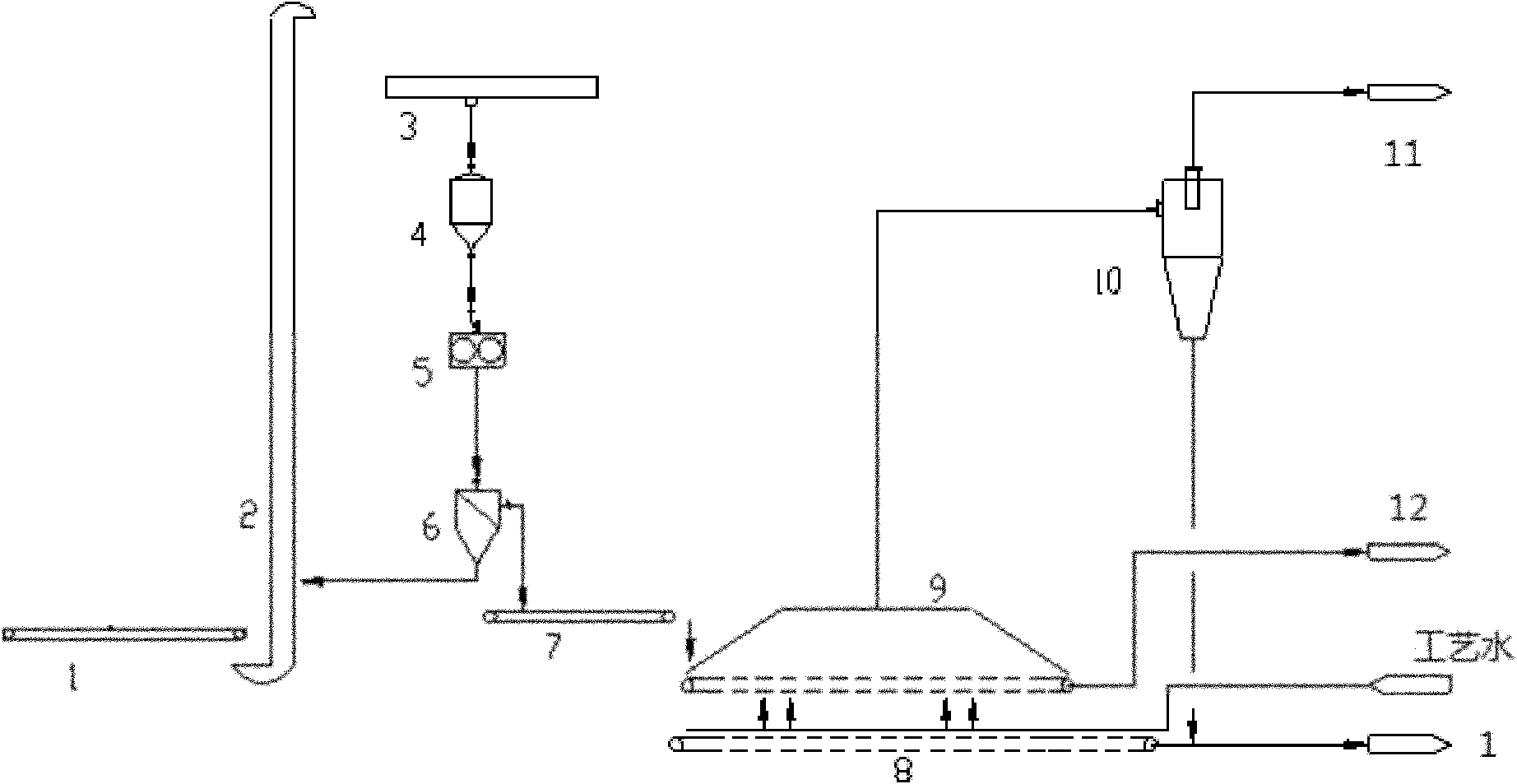

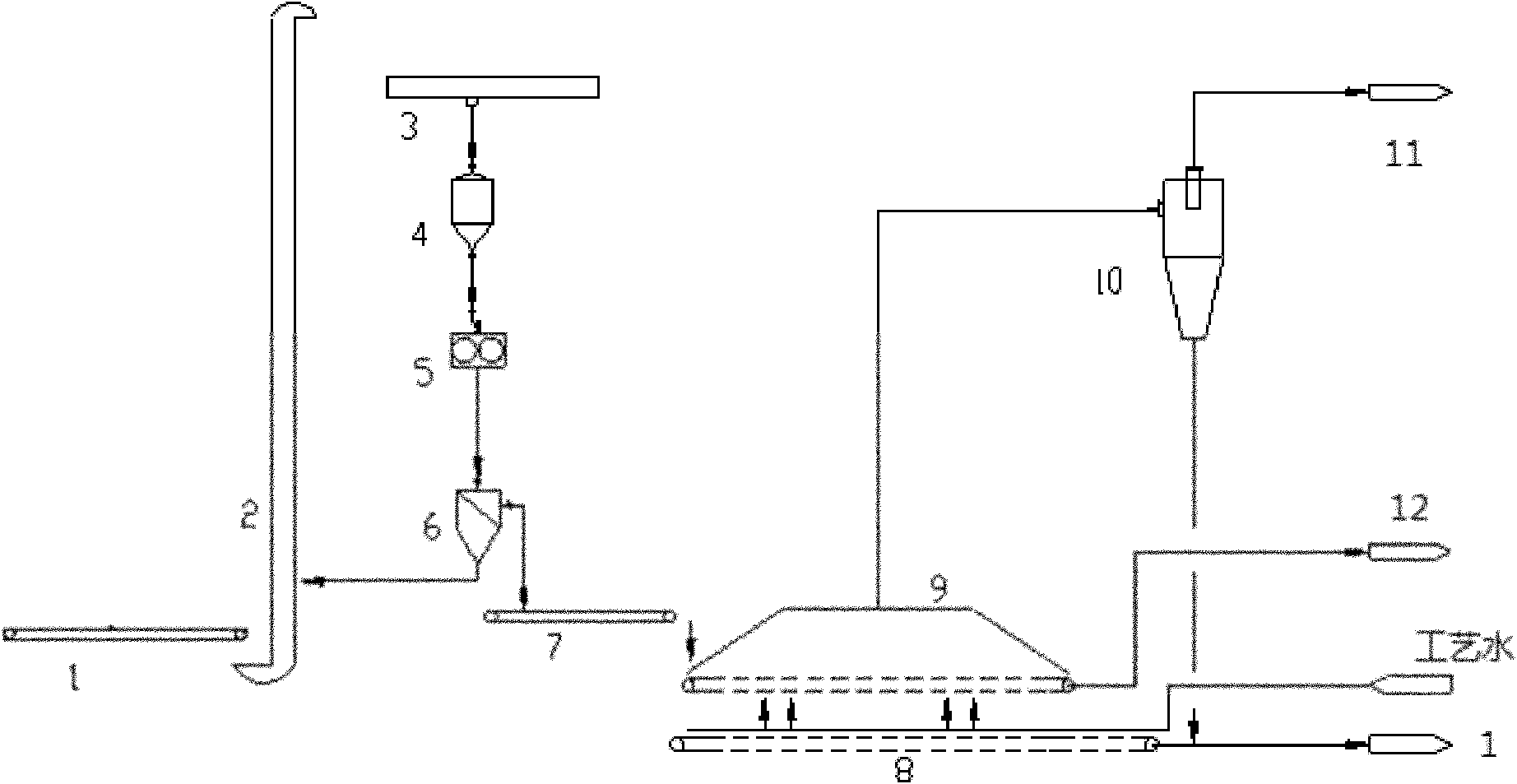

[0027] figure 1 Among them, the process of the present invention is:

[0028] 1) Send the lignite that meets the requirements of molding moisture content, temperature and particle size after drying, dehydration and quality upgrading into the molding device;

[0029] 2) The molding device extrudes lignite into coal molding, then screens the molding coal, and the qualified ones are transferred to the next step, and the unqualified ones are transferred to step 1);

[0030] 3) Qualified briquettes are air-cooled by air with water mist, and the cooled briquettes are sent into the finished product warehouse, and the coal powder / granules produced during cooling are sent back to step 1);

[0031] 4) The waste gas generated during cooling is collected and dedusted, then emptied or reused in other suitable sections, and the pulverized coal collected by the dedu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com