Microlens array, pixel island 3D display device and preparation method thereof

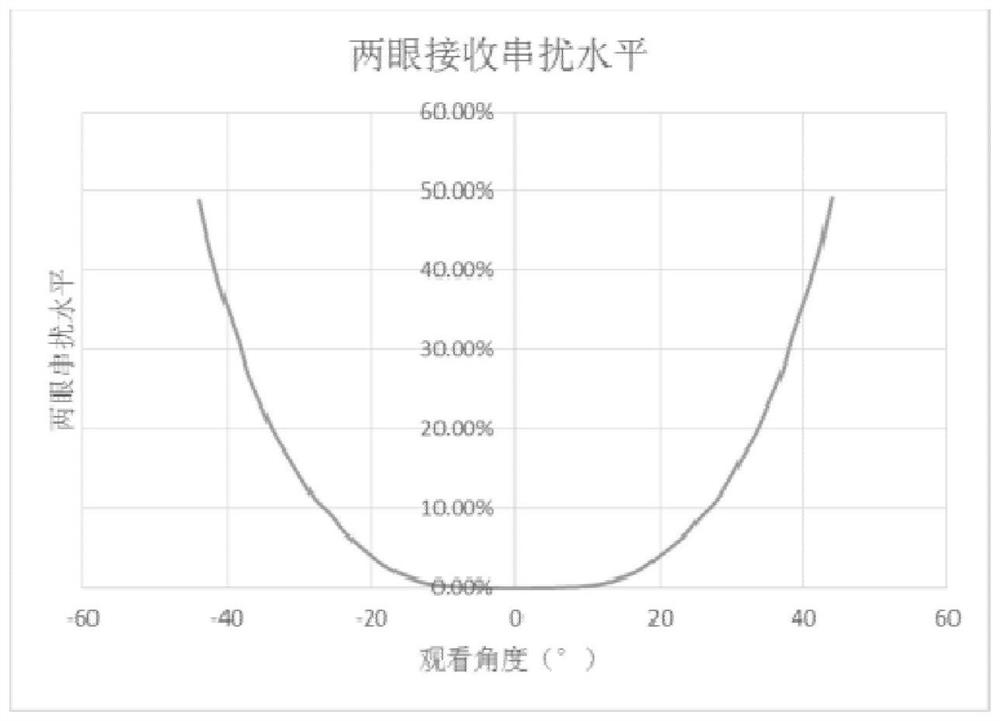

A technology of microlens array and lens array, applied in the field of 3D display, can solve the problems of light field 3D image crosstalk and moiré change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In order to solve the above technical problems, such as Figure 7-Figure 9 As shown, the present application provides a microlens 5 array, including: a first driving electrode 1, a liquid crystal film 2, a second driving electrode 3 and an organic medium layer 4 that are sequentially stacked along the light emitting direction of the display screen 6, preferably , the first driving electrode 1 and the second driving electrode 3 are arranged in a continuous structure, wherein the first driving electrode 1 and the second driving electrode 3 cover all sub-pixels 7; in a specific embodiment, the The outside of the lens 5 array structure is also wrapped with a flat layer 11; the organic medium layer 4 is provided with a lens 5 array structure, wherein the lens shape shown in this embodiment is not limited to the spherical shape shown in the figure, but also It can also be applied to cylindrical lenses, and the shape of the lens is not limited in this embodiment; under the act...

Embodiment 2

[0070] Compared with the array of microlenses 5 provided in Embodiment 1, the array of microlenses 5 proposed in this embodiment has the following differences: Figure 10 and Figure 11 As shown, one of the first driving electrode 1 and the second driving electrode 3 is set as a subdivision electrode, and the other is set as a continuous structure. In a specific embodiment, as Figure 10 As shown, the first driving electrode 1 is configured as a continuous structure, and the second driving electrode 3 is configured as a subdivided electrode. Preferably, the subdivided electrodes correspond to a plurality of sub-pixels 7 one by one; specifically, the scheme of the first embodiment is adopted After many experiments, the voltage difference required for each sub-pixel 7 is determined, and then the second driving electrode 3 shown in Embodiment 1 is refined, so that the second driving electrode 3 corresponding to each sub-pixel 7 Apply the required voltage difference; when it is n...

Embodiment 3

[0077] Compared with the array of microlenses 5 provided in Embodiment 1, the array of microlenses 5 proposed in this embodiment has the following differences: Figure 13 As shown, the first driving electrode 1 and the second driving electrode 3 are both configured as subdivision electrodes.

[0078]According to an embodiment of the present invention, the subdivision electrodes correspond to a plurality of sub-pixels 7 one-to-one. Of course, each sub-electrode in the subdivision electrodes corresponds to a plurality of sub-pixels 7. Of course, a one-to-many arrangement The corresponding resolution is lower than the resolution corresponding to the one-to-many setting method. In actual use, it is preferable to adopt a one-to-one correspondence between multiple sub-electrodes in the subdivision electrodes and the sub-pixels 7. On the one hand, the resolution can be guaranteed, and on the other hand, On the one hand, precise control of each sub-pixel 7 can also be realized. To sum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com