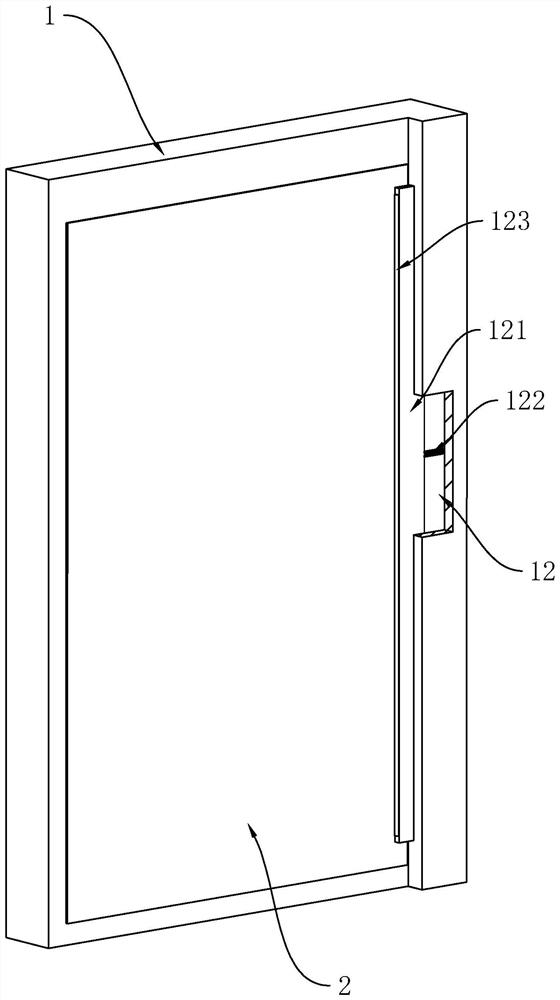

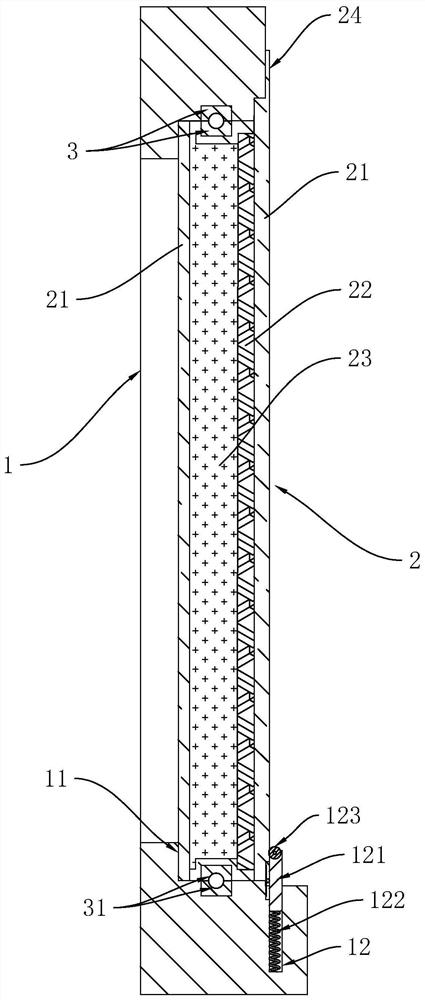

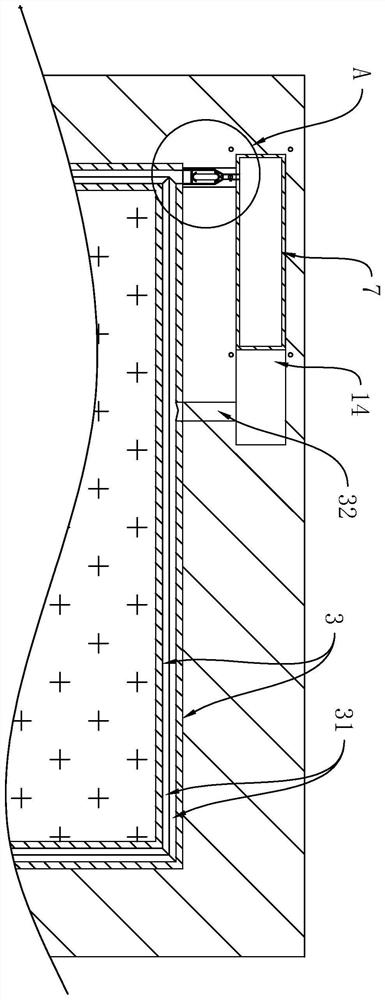

Fire escape door and its manufacturing process

A technology for access doors and door frames, which is applied in the field of fire doors, can solve problems such as dense smoke penetration, and achieve the effect of increasing fire resistance and facilitating replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0058] Embodiment 2: A manufacturing process of a fire escape door, comprising the following steps:

[0059] Step 1. Forming the parts of the door frame and door leaf, designing the drawings of each part according to the door frame and door leaf to be processed, and selecting steel plates to carry out shearing, stamping and bending according to the drawings of each part to form the molding of each part;

[0060] Step 2. Reinforce the parts of the door frame and door leaf, analyze the force of the door frame and door leaf to be processed when they are in use, and weld reinforcements for the main supports and parts with more stress. The reinforcements can be ribs or ribs;

[0061] Step 3, door frame assembly and welding, each part of the door frame is assembled and welded to form a door frame;

[0062] Step 4: The door leaf is filled with glued hot pressing, and the inside of the door leaf is filled with a fireproof board and an inorganic fireproof door core, and glued and hot p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com