Device and method for adding copper balls or tin balls in electroplating line of printed board

A technology of adding devices and copper balls, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of copper balls/tin balls slipping and loss, cumbersome adding work, dissatisfaction with titanium baskets, etc., to achieve material saving, simple structure and low cost , Solve the effect of adding dissatisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

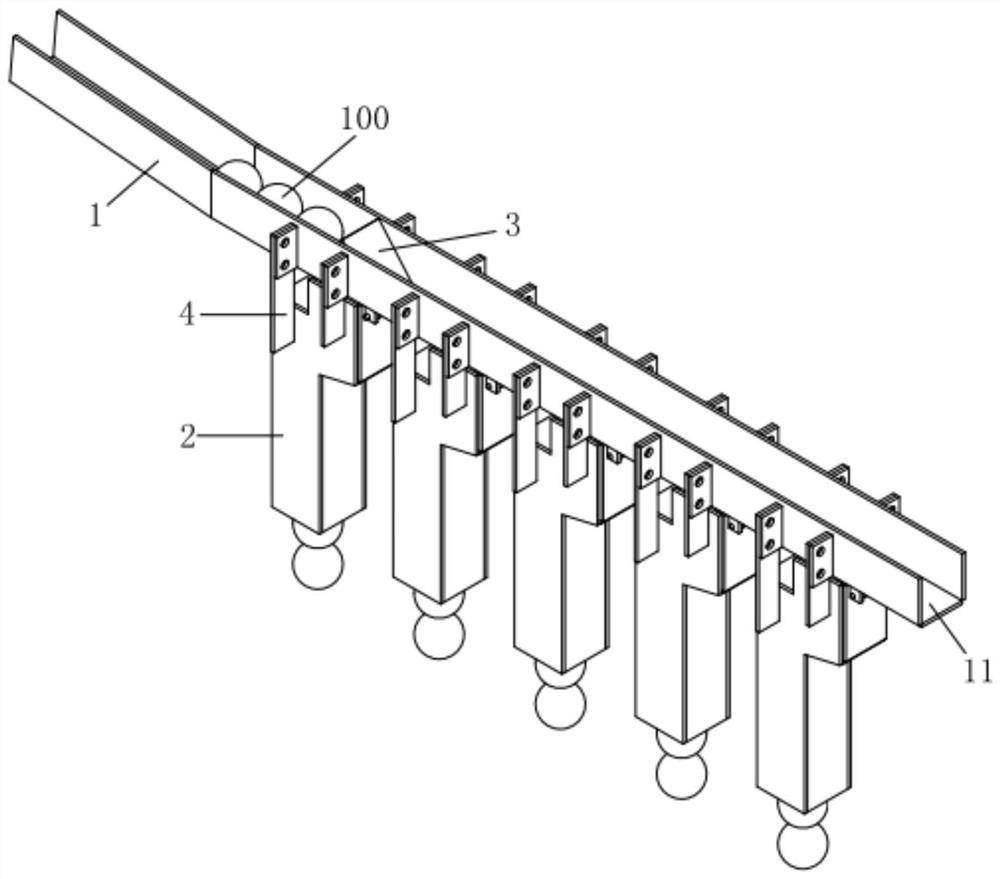

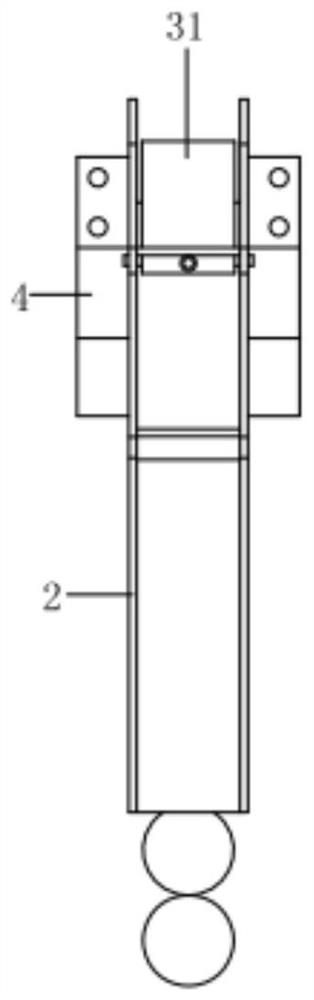

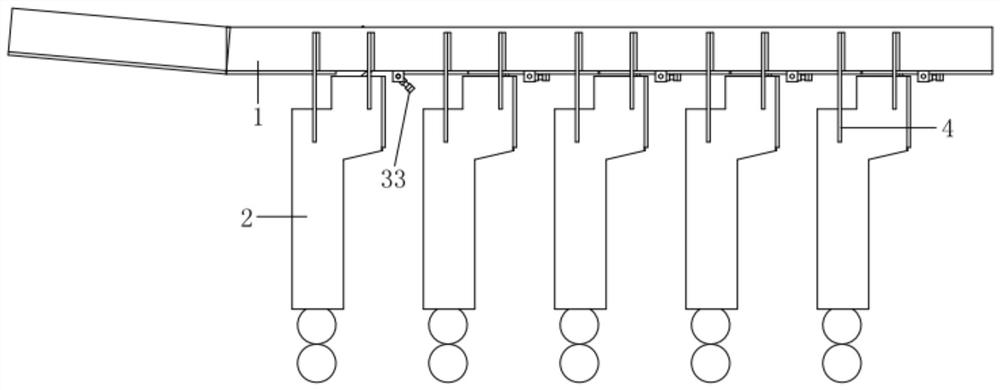

[0032] Such as Figure 1-6 As shown, a device for adding copper balls or tin balls in a printed board electroplating line shown in this embodiment includes an introduction slot 1 for introducing copper balls or tin balls 100, and a plurality of intervals are arranged in the introduction slot 1. Adding slots 2 arranged in sequence from front to back at the lower end and a plurality of turnover mechanisms 3 arranged on the rear side of adding slots 2 in one-to-one correspondence, that is, the number of the flipping mechanisms is consistent with that of the adding slots; The shape is U-shaped, and the inner side of the U-shape forms a U-shaped groove 11 through which the copper ball or tin ball is conveyed forward. The leading end of the lead-in groove is set obliquely, that is, a landslide is provided at the front end, so that the copper ball or tin ball is affected by gravity Convey forward along the landslide and U-shaped groove; the through-hole 21 for the copper ball or tin ...

Embodiment 2

[0042] The invention also discloses a method for adding copper balls or tin balls in the electroplating line of printed boards. The adding device as described in Embodiment 1 is used for adding, wherein, the lower end of each adding groove is connected with a titanium basket, and the adding The method includes the following steps:

[0043] a. Put the copper ball or tin ball from the lead-in end of the lead-in trough, so that the copper ball or tin ball is conveyed forward along the lead-in trough;

[0044] b. After the copper ball or tin ball reaches the position of the first adding slot, the flip mechanism automatically opens the opening under pressure so that the copper ball or tin ball falls into the adding slot and enters the corresponding titanium basket, and then the flip mechanism is in the position of the reset part Rotate upwards and reset under the action, so that the next copper ball or tin ball will fall into the adding slot again, and use the reset mechanism to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com