A steel tube concrete column

A steel pipe concrete column and concrete technology, applied in the direction of columns, pillars, pier columns, etc., can solve the problems that the synergy between circular steel pipes and concrete is not well exerted, the bearing capacity has not been improved, and continuous cracking cannot be suppressed, etc. To achieve the effect of inhibiting continuous cracking, inhibiting cracking, and strengthening the effect of tightening the hoop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following specific examples are only explanations of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications without creative contribution to the present embodiment as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

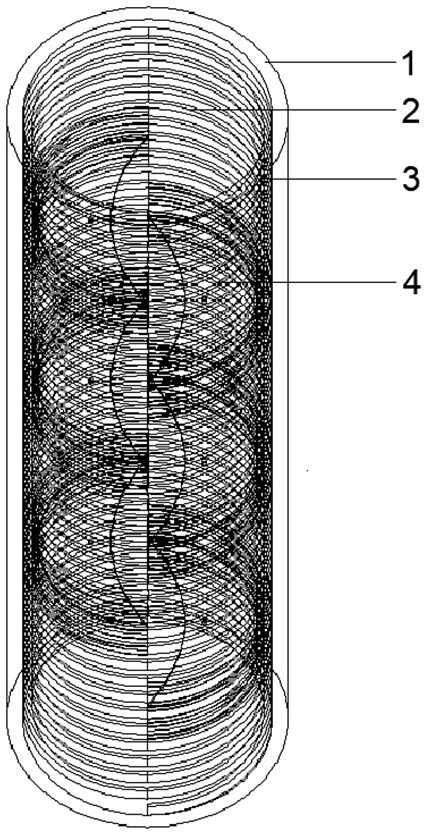

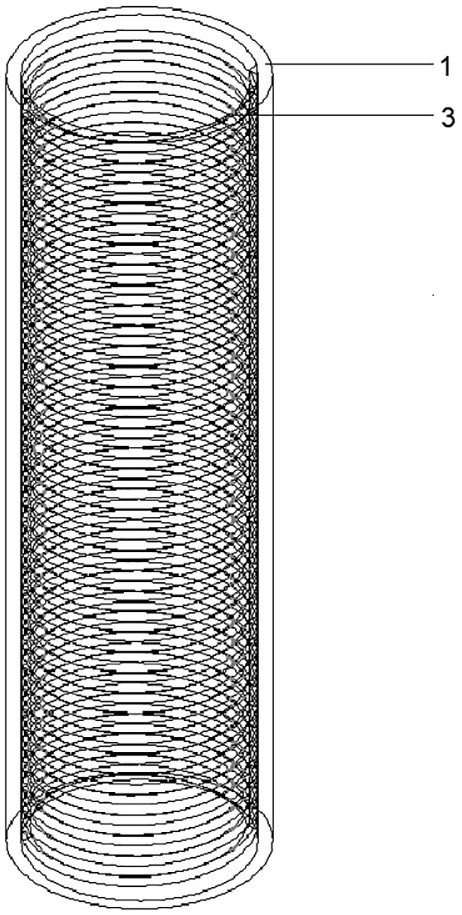

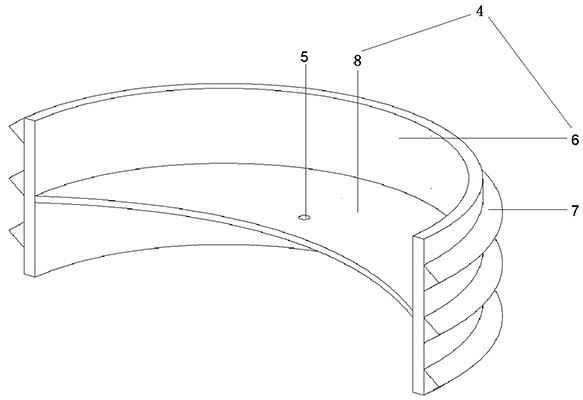

[0022] figure 1 The shown concrete-filled steel tube column is composed of steel tube 1 , stiffener 4 and concrete 2 . The inner side of the cross-section of the steel pipe 1 is circular, and the outer side of the cross-section can adopt other shapes. In this embodiment, a circular steel pipe with a round inner and outer cross-section is preferably used. The inner wall of the steel pipe 1 is provided with an internal thread 3 for the installation of the stiffener 4. Since the steel pipe concrete column is under great pressure during use, the strength of the threaded connection between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com