Multifunctional automatic gap filling machine

A caulking machine and multi-functional technology, applied in the field of machinery, can solve the problems of long time-consuming, bulky equipment, inconvenient operation, etc., and achieve the effect of convenient operation and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

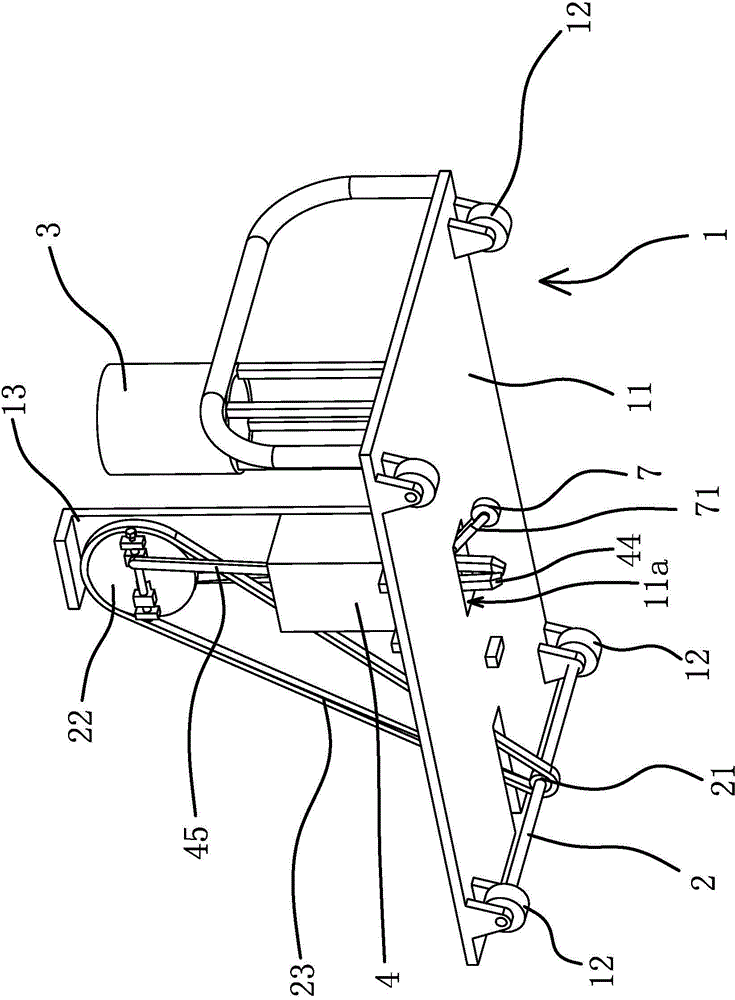

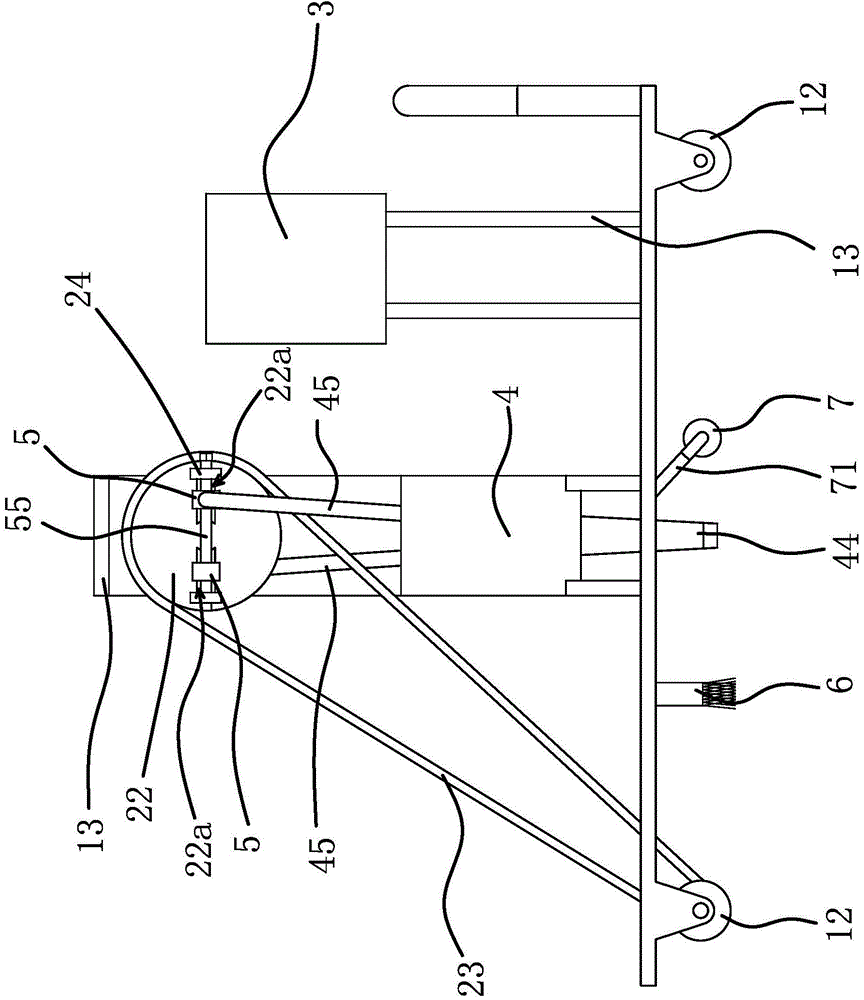

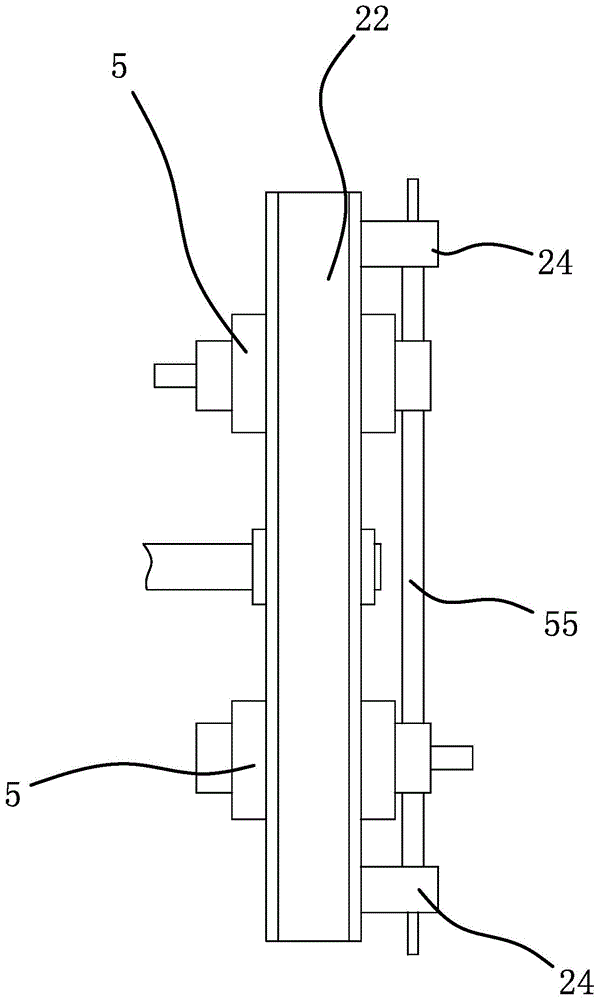

[0024] This example Figure 1 to Figure 5 As shown, the multifunctional automatic caulking machine includes a trolley 1, a caulking cylinder 4 fixed on the trolley 1 and a storage tank 3, the storage cylinder 3 is located above the caulking cylinder 4, and the material storage cylinder 3 is unloaded The opening is connected with a feeding conduit 31, and the trolley 1 includes a base plate 11, a wheel 12 arranged on the base plate 11 and a fixed frame 13 fixed on the base plate 11, the base plate 11 is provided with a through hole 11a, and the wheels 12 are connected with a rotating shaft 2. The axis line of the rotating shaft 2 is in line with the center line of the wheel 12. The driving pulley 21 is fixed on the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com