Equipment for manufacturing three-dimensional object and powder feeding device thereof

A technology of three-dimensional object and powder feeding device, applied in the field of additive manufacturing, can solve the problems of insufficient powder feeding amount, underfilled powder, poor powder fluidity, etc., and achieve the effect of ensuring powder feeding stability and enhancing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to allow those skilled in the art to better understand and realize the technical solution of the present invention, further detailed description will be given below in conjunction with the accompanying drawings and specific embodiments.

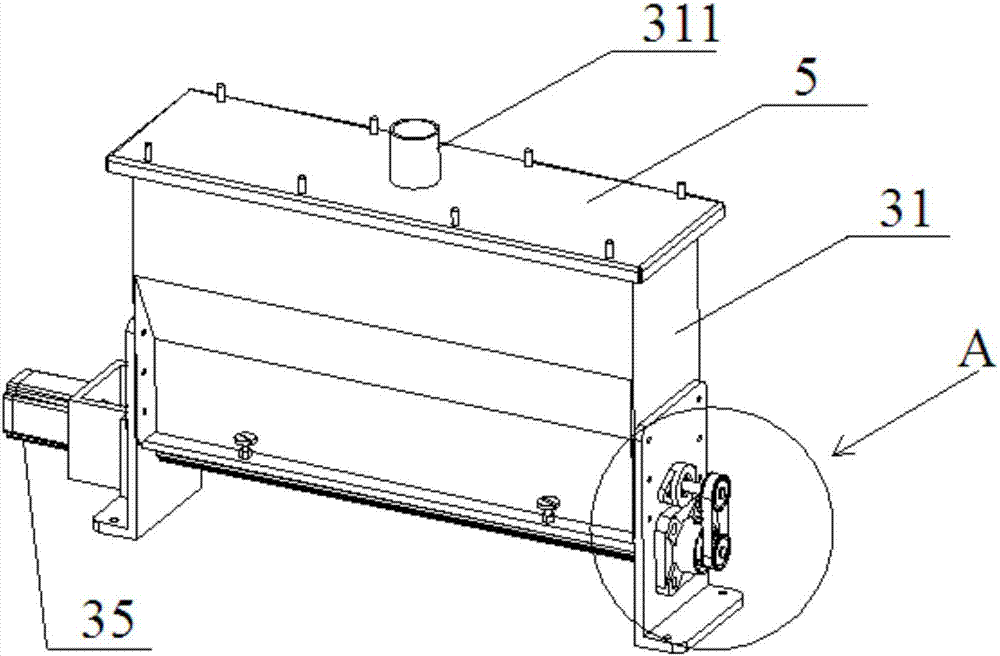

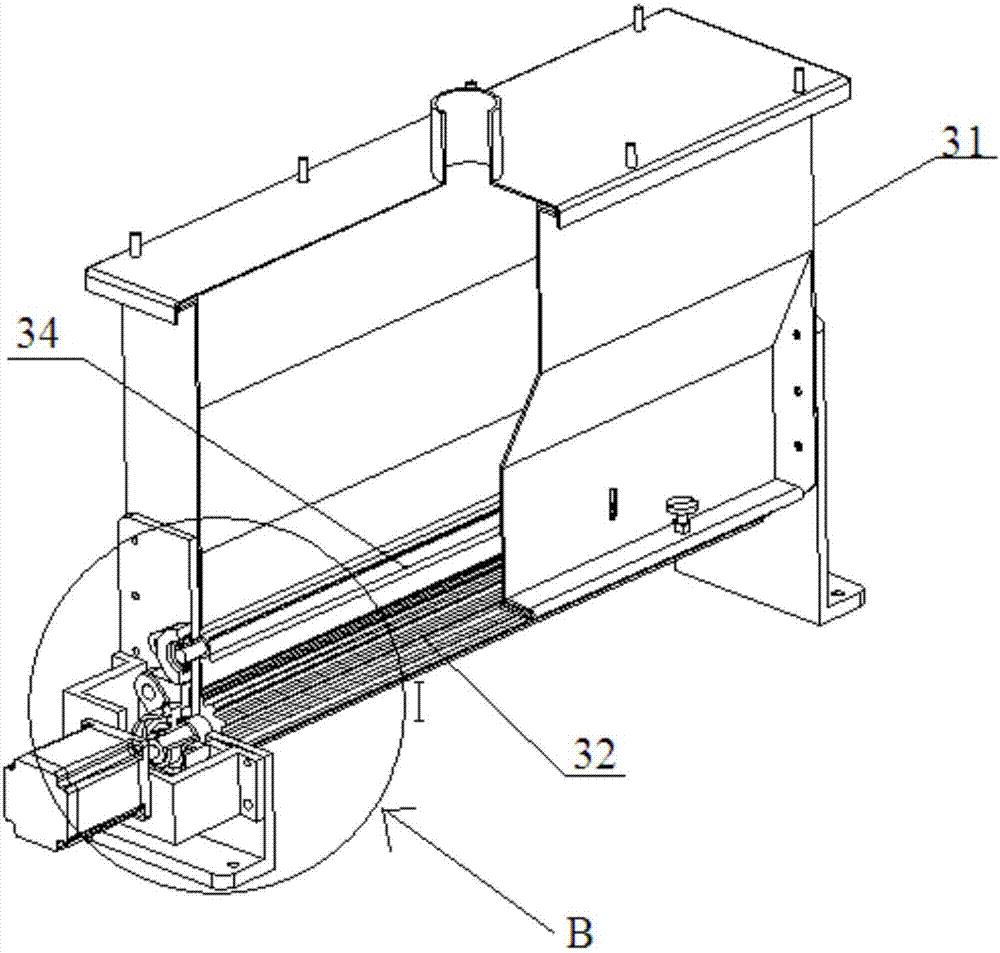

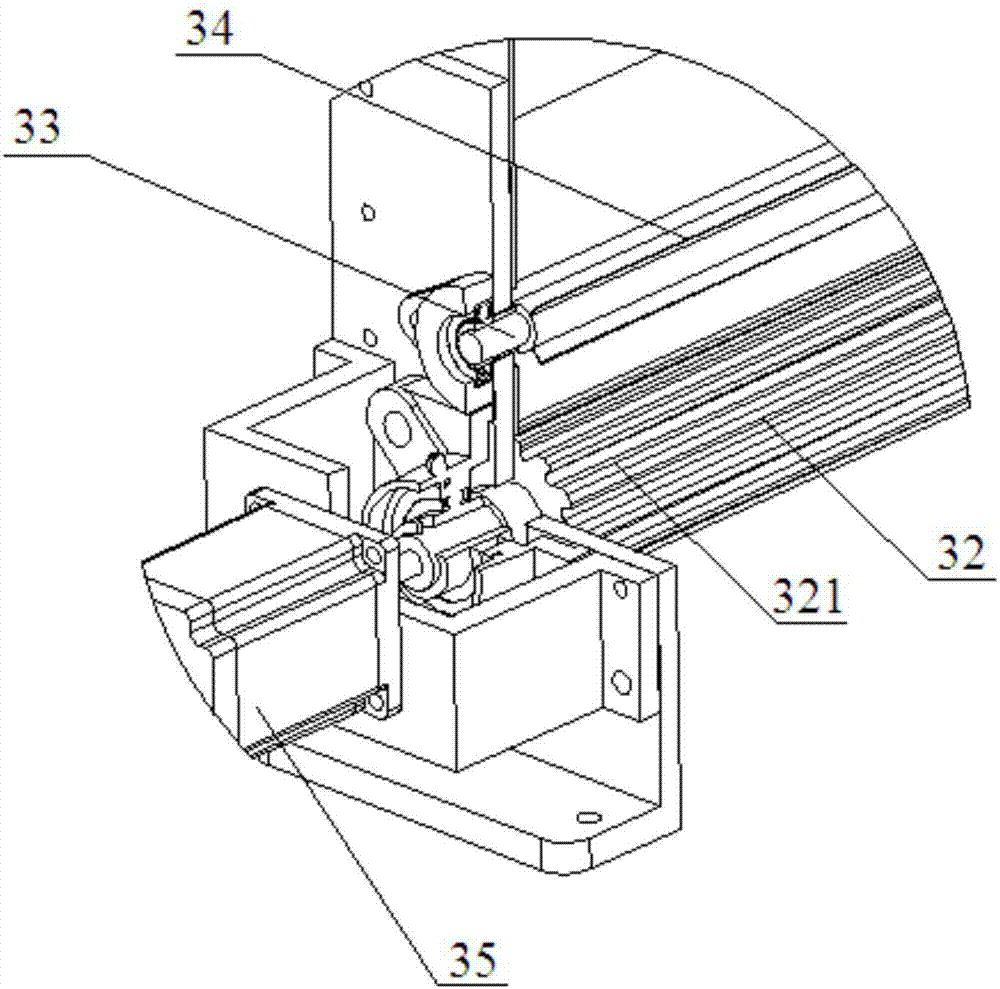

[0028] The invention provides a powder feeding device for manufacturing three-dimensional objects, which includes a powder feeding box with an opening at the bottom, a powder driver, a roller with several grooves, and a driving mechanism for driving the roller to rotate. The powder driver is set in the powder feeding box, and the roller is set at the bottom opening of the powder feeding box, and through the close cooperation with the bottom opening of the powder feeding box, the powder in the powder feeding box is more compact under the action of the powder driver. Smoothly enter the groove of the roller, and then fall from the groove through the rotation of the roller to achieve powder feeding.

[0029] The above-mentioned cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com