Steel sheath type steel truss web node structure

A steel sheath and node technology, applied in bridge parts, bridges, buildings, etc., to achieve the effects of high bearing capacity and rigidity, simple operation and less welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

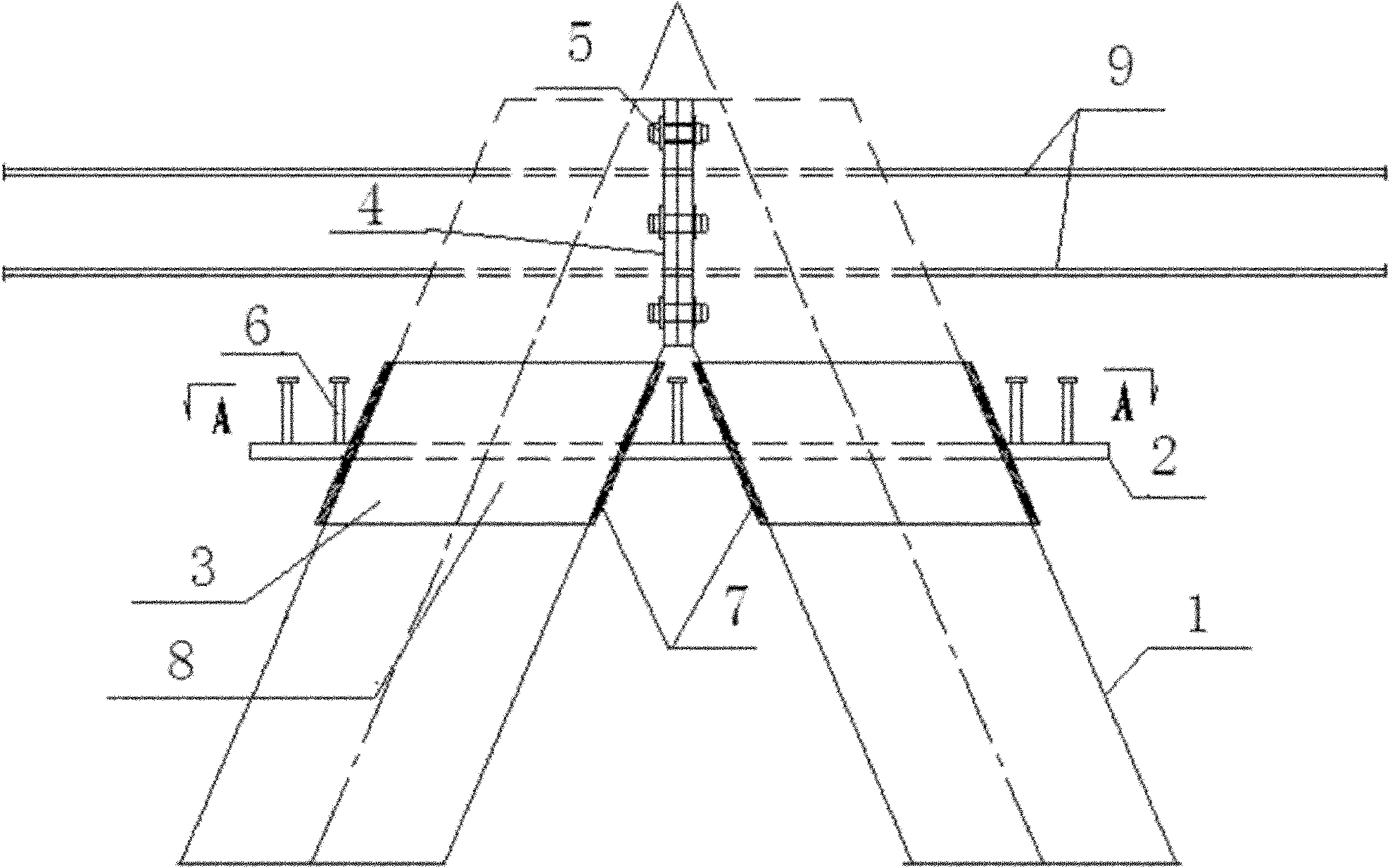

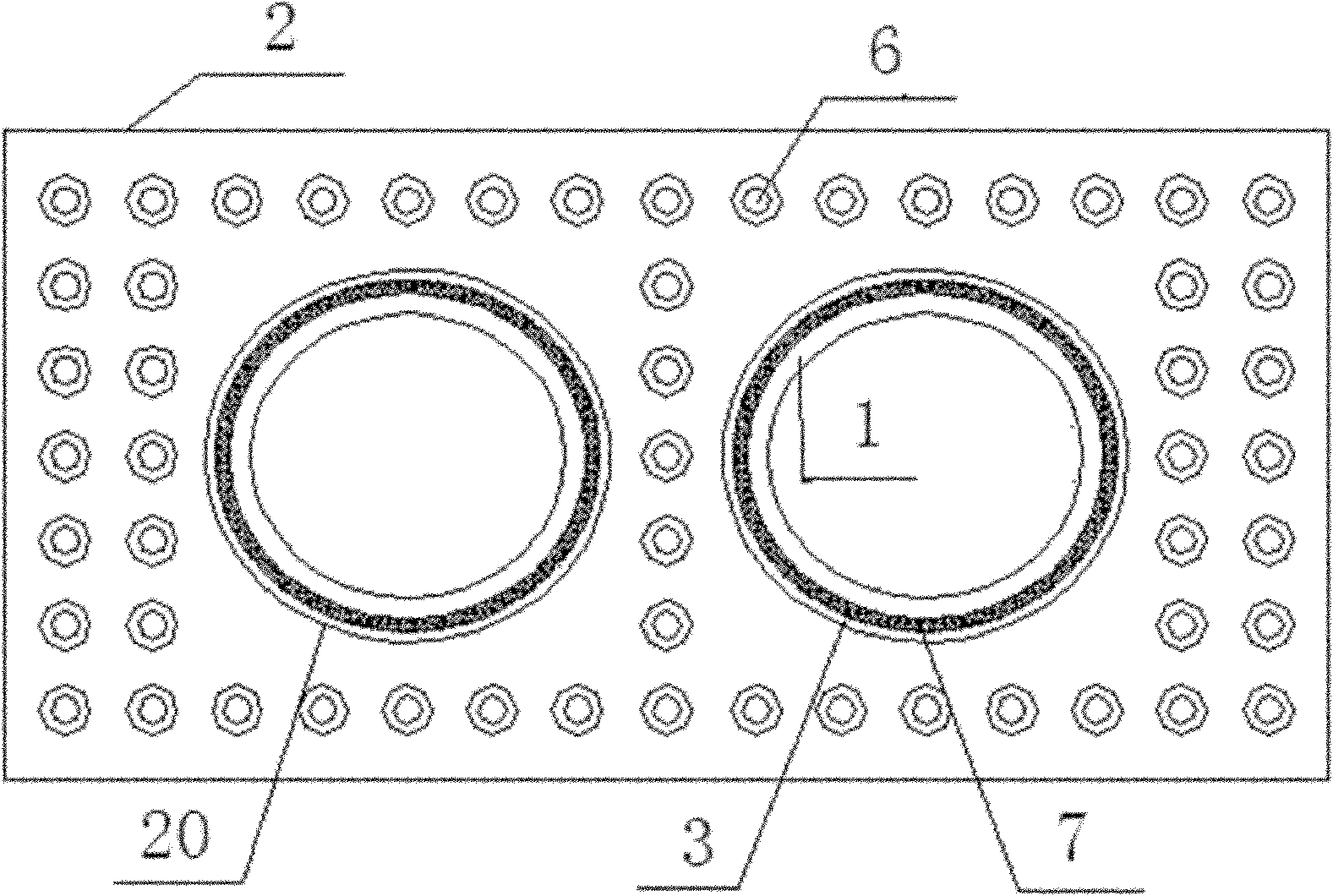

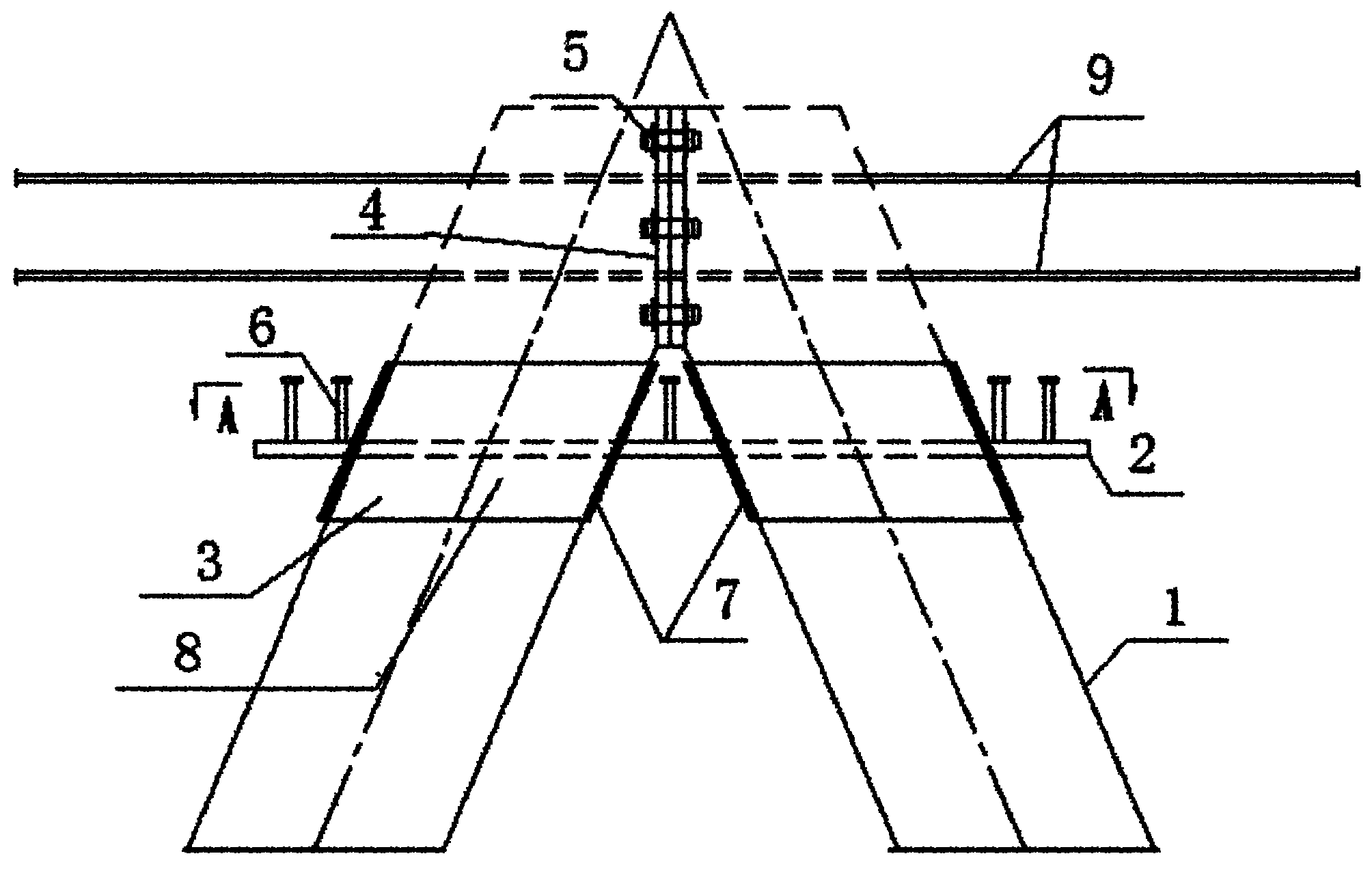

[0019] like figure 1 As shown, the steel sheath form truss web node structure, two truss web steel pipes 1, horizontal steel plate 2 and oblique steel sheath 3 are arranged at the node; the horizontal steel plate 2 is parallel to the top and bottom plates, and two truss web steel pipes 1 respectively into a diagonal steel sheath 3 on a horizontal steel plate. Fill epoxy mortar or high-flow cement mortar 7 between the inclined steel sheath 3 and the truss web steel pipe 1 to ensure compactness and adjust construction errors. The inner and outer sides 8 of the oblique steel sheath are roughened to reduce interface slippage. The truss-web steel pipes 1 embedded in the roof and floor concrete are set facing each other in a "herringbone" shape, and the intersections are respectively cut vertically, and the cut surfaces are respectively welded to the steel plate 4 for sealing. The steel plates 4 of the steel pipes are riveted together by ordinary bolts 5, so that the two truss we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com